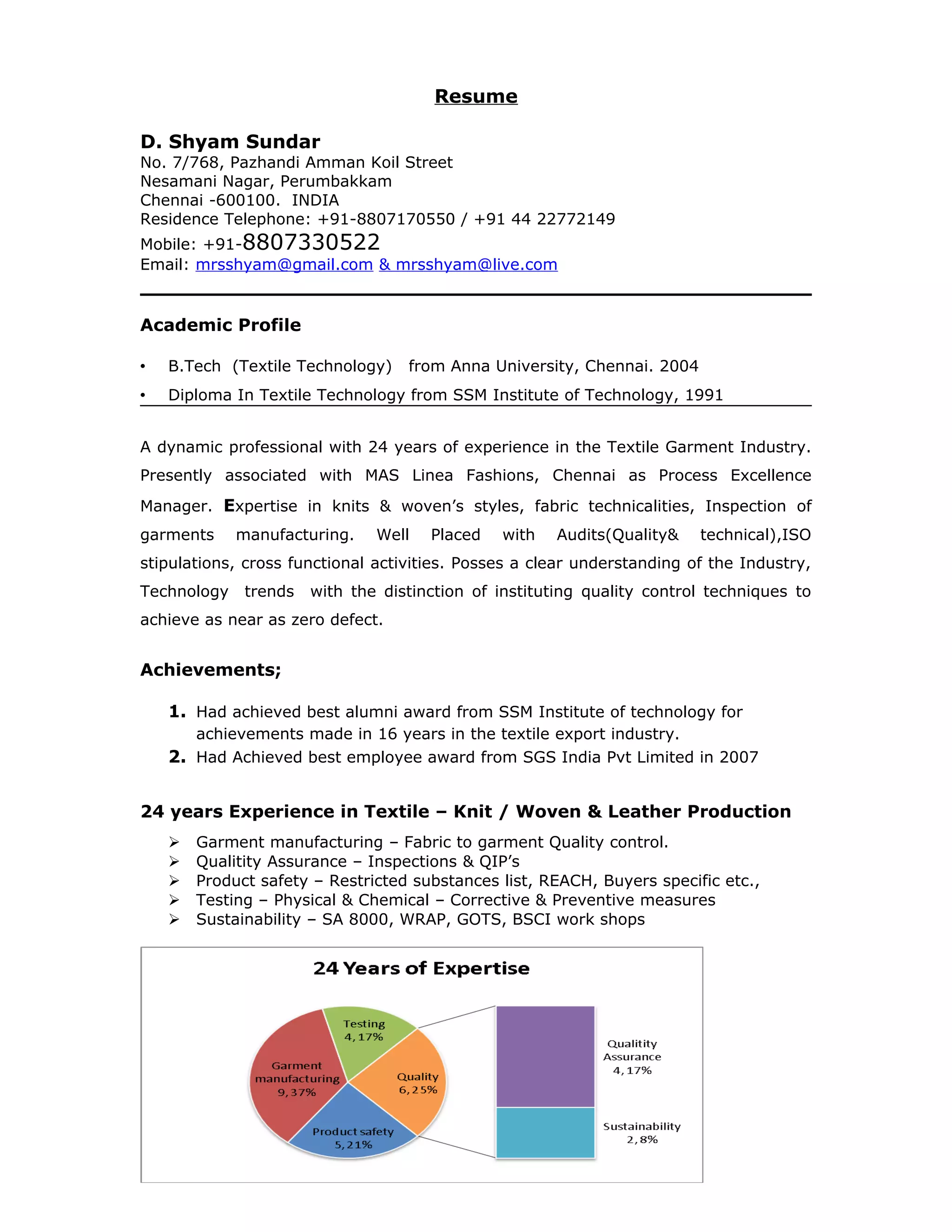

The document is a resume for D. Shyam Sundar. It summarizes his educational qualifications and over 24 years of experience in textiles and garment manufacturing in roles focused on quality assurance and product safety. It details his most recent roles as Process Excellence Manager at MAS Linea Fashions India and prior experience as Technical Manager at Jupiter Knitting Company and in product safety roles at C&A Sourcing International and S.Oliver.