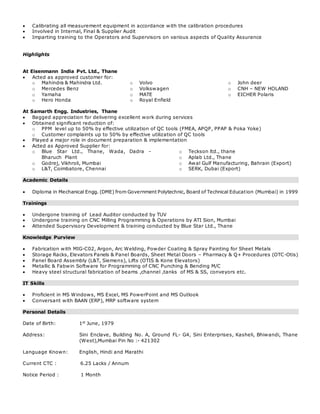

Lalit Kumar is seeking a senior level quality control role preferably in Mumbai. He has over 15 years of experience in quality control, supplier management, and team management. He is proficient in quality assurance processes, coordinating with departments, managing suppliers, and ensuring compliance with standards. Lalit Kumar also has experience in root cause analysis, communication, problem solving, and using quality tools. He is looking for a quality control role where he can apply his experience in project management, quality monitoring systems, auditing, and achieving quality targets.