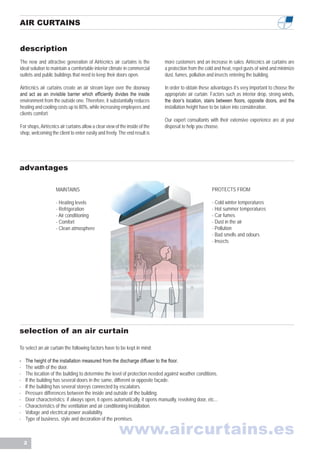

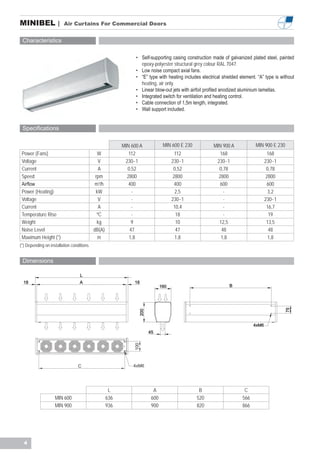

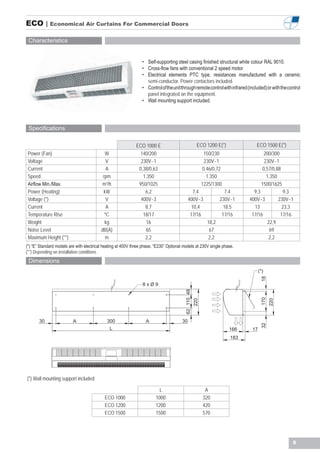

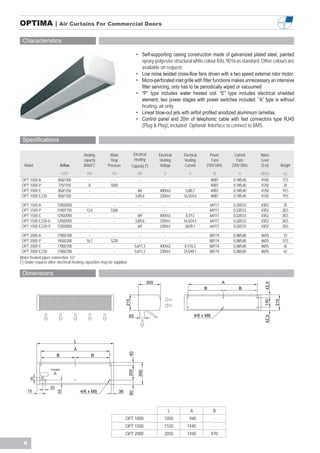

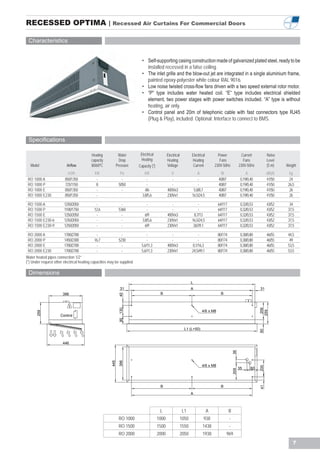

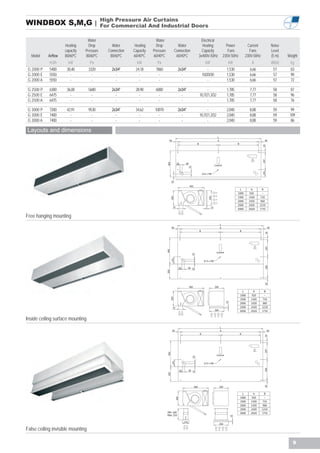

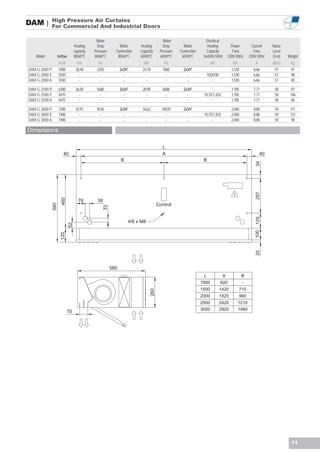

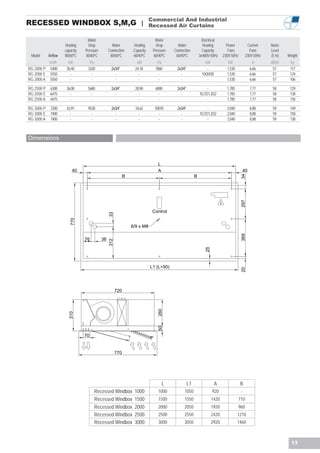

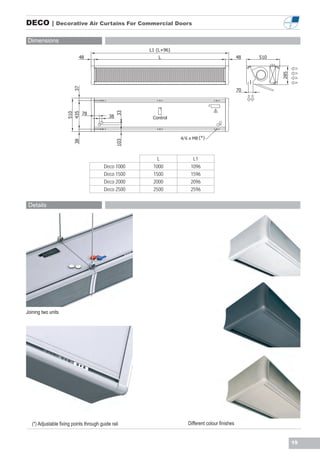

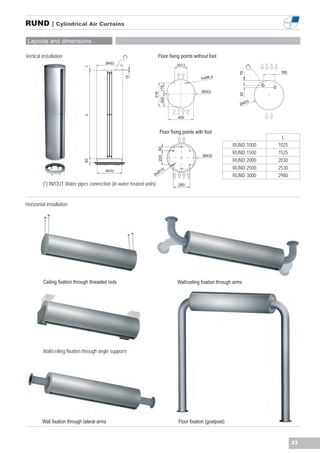

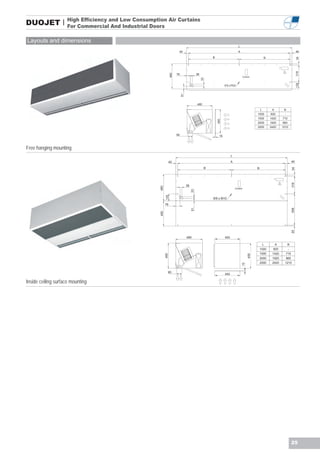

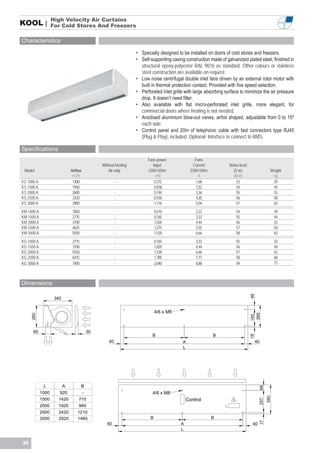

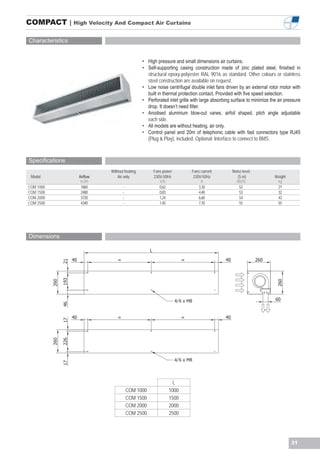

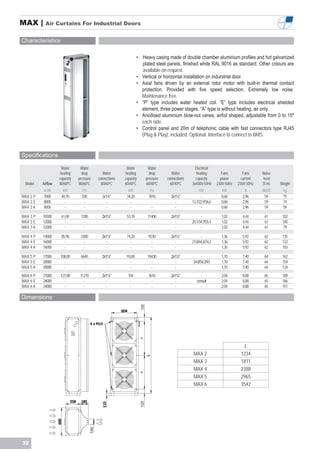

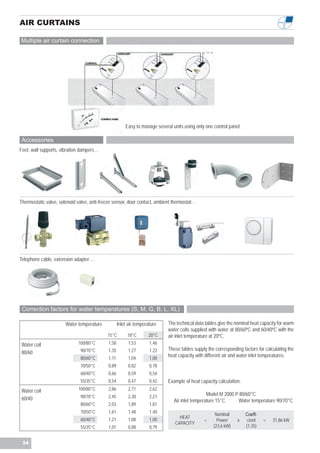

The document describes airtècnics air curtains, which are designed to maintain a comfortable indoor climate, reduce energy costs, and protect against external elements such as cold, heat, dust, and insects. It emphasizes the importance of selecting the appropriate air curtain based on various factors like building height, door width, and environmental conditions. The document also details specifications and applications for different models of air curtains suitable for various commercial settings.