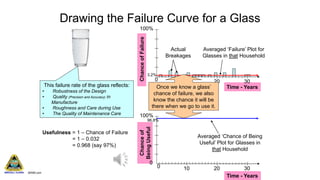

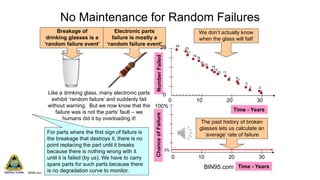

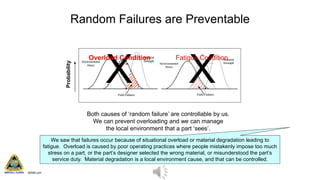

The document discusses the critical factors influencing the reliability of equipment, including design control, manufacturing precision, operational practices, and maintenance. It emphasizes that without addressing all these factors collectively, achieving high reliability in operations is unlikely. The text also explores measuring reliability through failure rates and the chance of failure, using the example of glasses to illustrate these concepts.