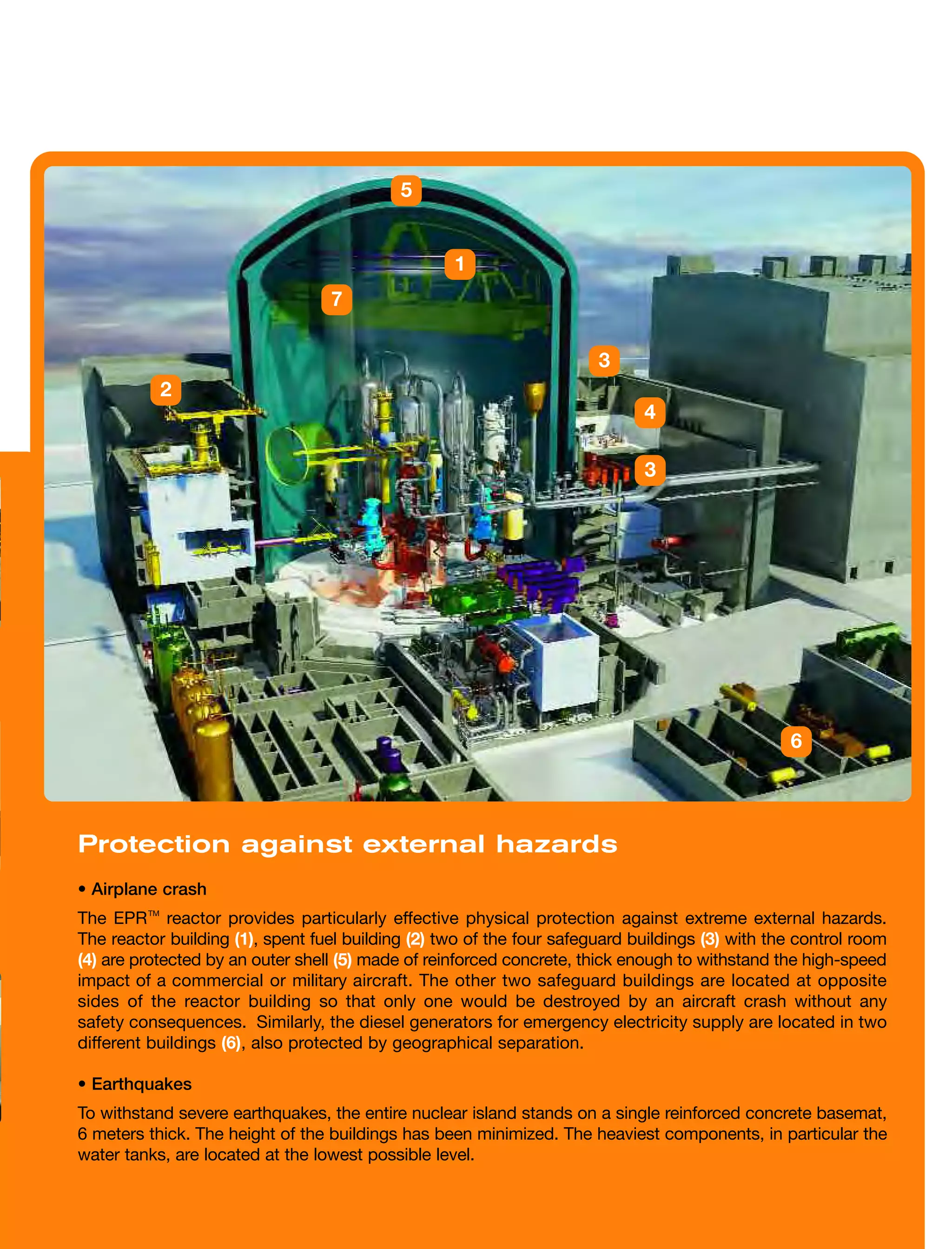

The document discusses the advantages of the EPR nuclear reactor design from AREVA, highlighting its safety, economic competitiveness, and environmental friendliness. The EPR design builds on decades of nuclear experience and incorporates multiple layers of redundancy and safety systems to prevent core meltdowns. It offers high power output, efficiency, and availability to reduce generation costs compared to gas plants. The EPR also provides operating flexibility and can meet different fuel and power needs while minimizing environmental impact over its lifetime.