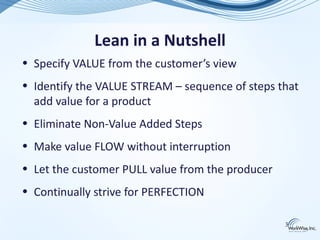

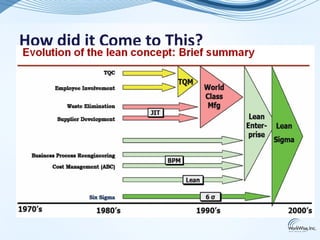

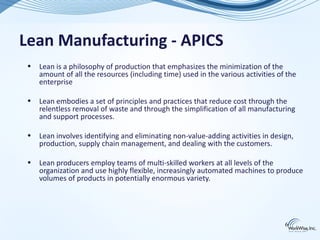

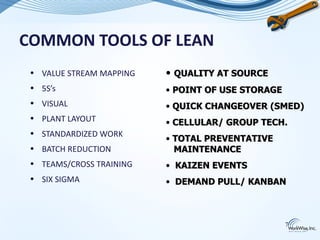

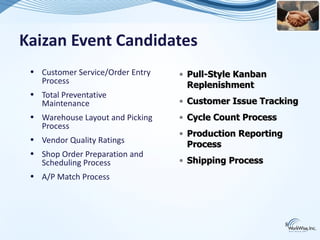

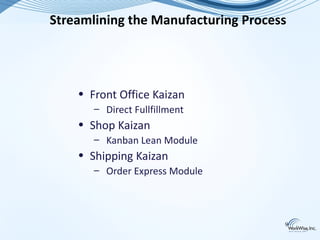

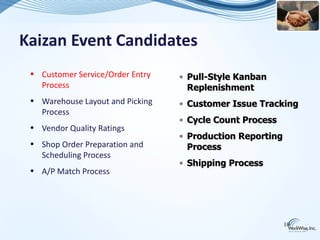

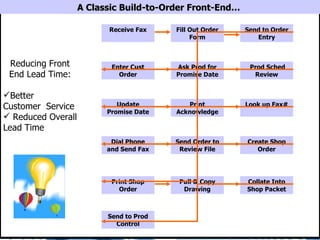

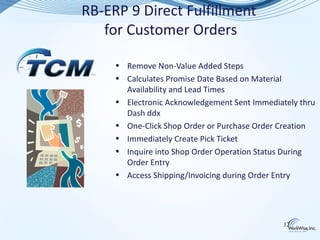

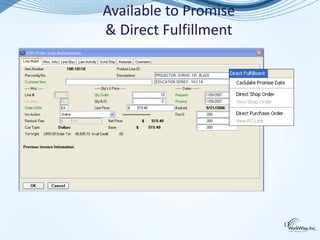

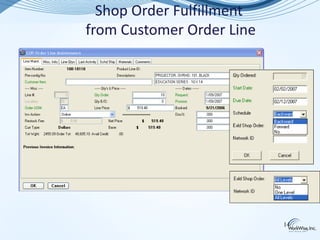

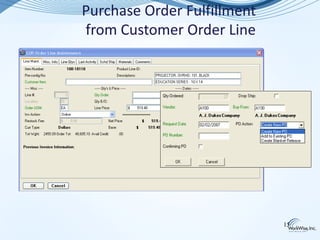

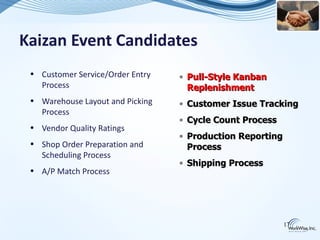

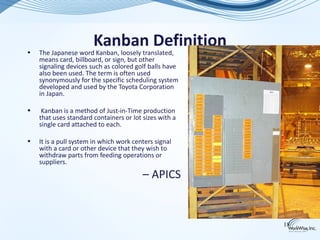

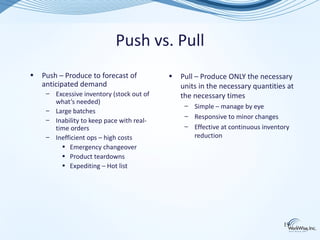

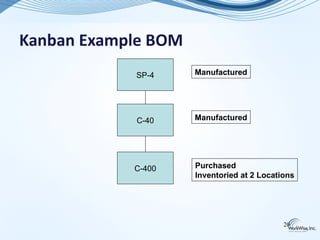

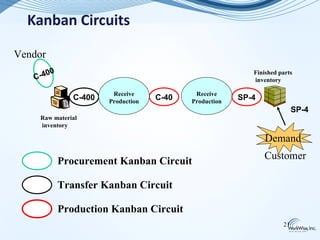

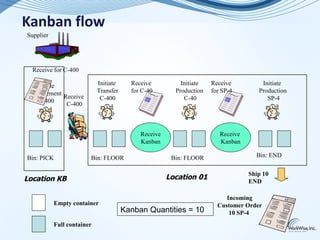

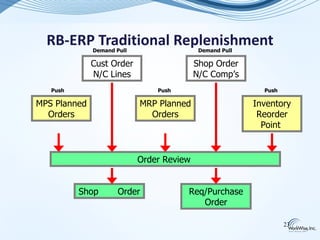

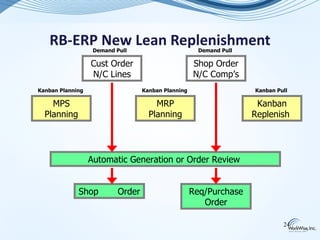

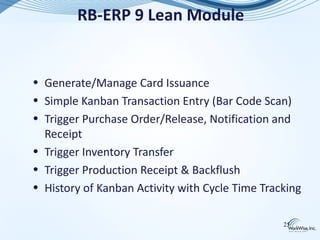

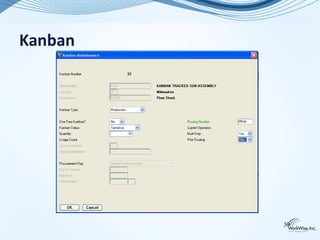

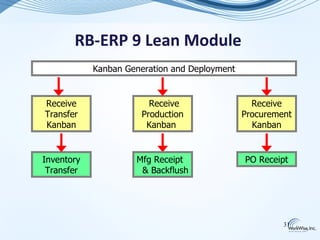

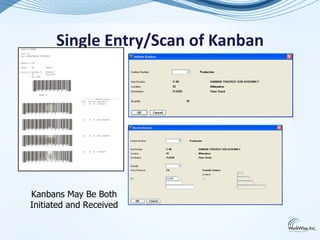

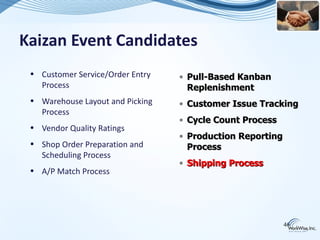

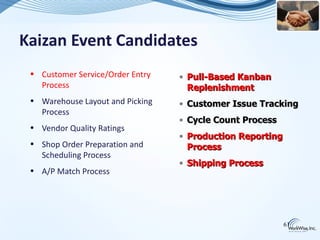

The document discusses how lean manufacturing principles like Kanban can help streamline the manufacturing process. It provides examples of how WorkWise & RB-ERP software can eliminate non-value added steps in processes like order entry, production, and shipping through features like direct order fulfillment and pull-based Kanban replenishment. The document also outlines common lean tools and gives examples of how a manufacturer implemented lean to reduce lead times and improve customer service.