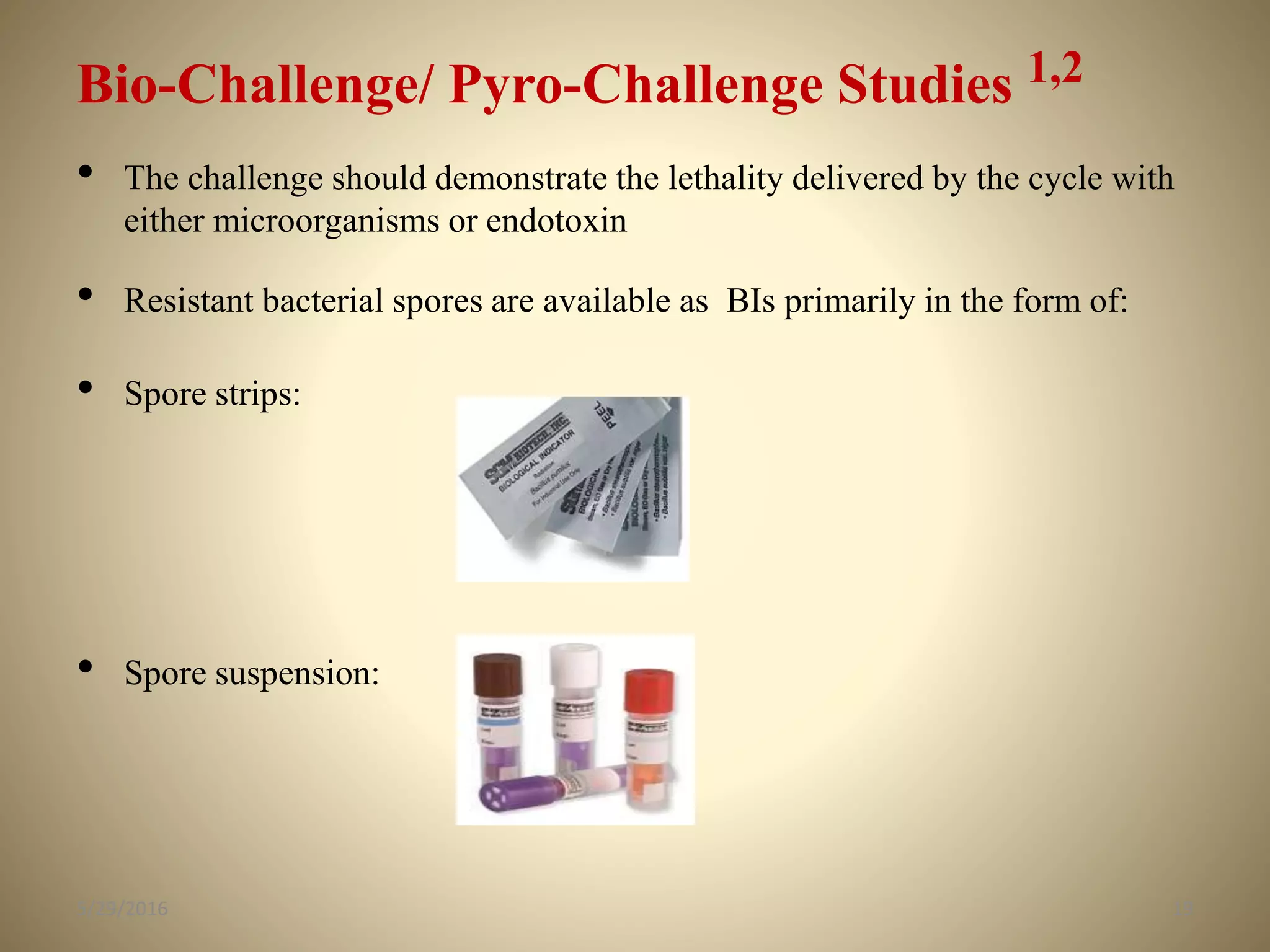

The document outlines the equipment validation process for hot air ovens in pharmaceutical settings, detailing its importance for ensuring compliance and efficacy in sterilization. It covers types of dry heat sterilizers, validation approaches including design, installation, operational, and performance qualifications, as well as ongoing monitoring and documentation requirements. The conclusion emphasizes the necessity of thorough validation as a means to guarantee that equipment meets predefined operational standards.

![EQUIPMENT VALIDATION :

HOT AIR OVEN

5/29/2016 1

Mr. Sagar Kishor Savale

[Department of Pharmaceutics]

avengersagar16@gmail.com

2015-2016

Department of Pharmacy (Pharmaceutics) | Sagar savale](https://image.slidesharecdn.com/equipmentsvalidation-160529055136/75/EQUIPMENT-VALIDATION-HOT-AIR-OVEN-1-2048.jpg)