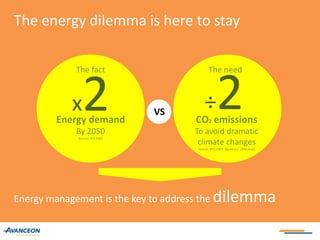

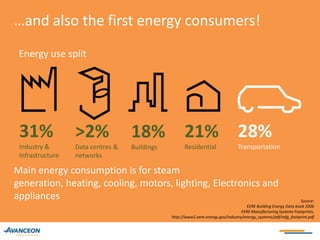

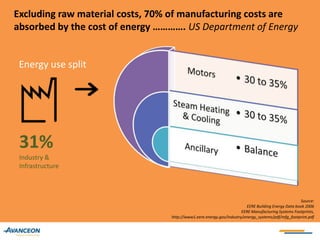

1) The document discusses the growing global energy demand and CO2 emissions challenge, noting that world energy consumption has risen 45% since 1980 and is projected to increase 70% more by 2030, driven largely by emerging markets.

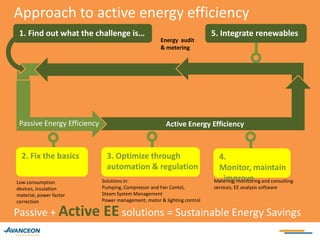

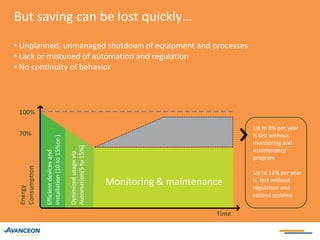

2) It argues that energy management through optimization of existing infrastructure can achieve 30% global energy savings and proposes focusing first on optimizing processes, buildings, and equipment which can deliver fastest impact within 1-5 years.

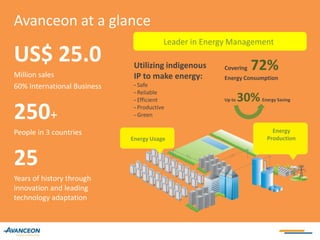

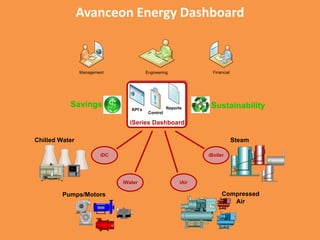

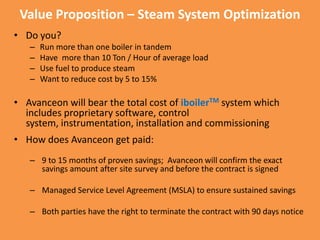

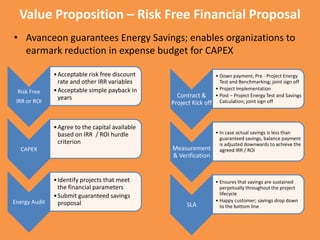

3) The company, Avanceon, provides integrated energy efficiency solutions including monitoring, automation, and optimization of steam, water, air, and power systems aimed at delivering guaranteed energy savings of 5-15% for industrial and commercial clients.