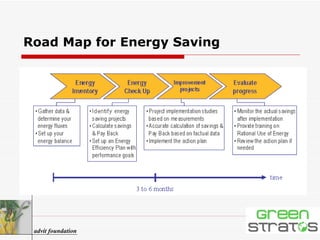

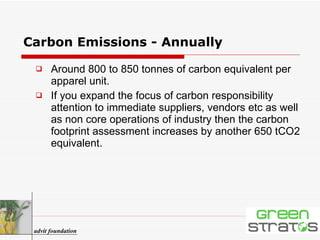

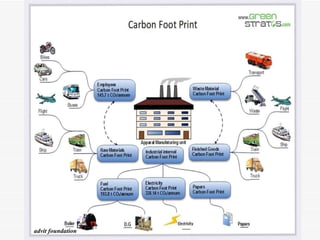

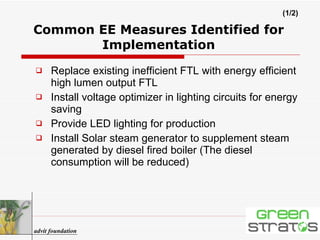

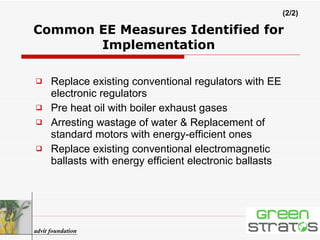

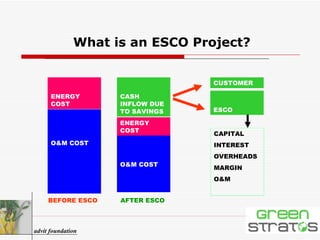

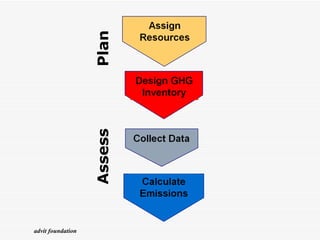

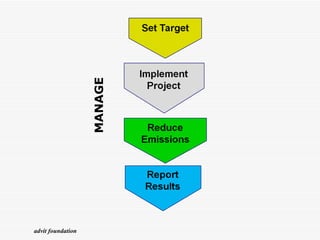

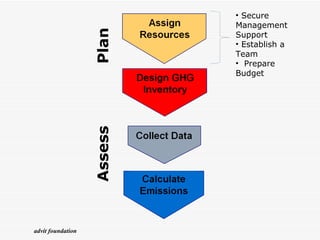

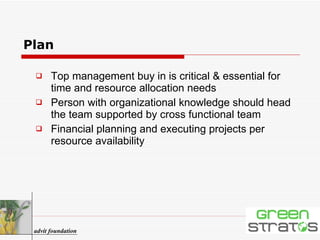

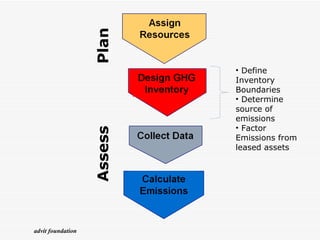

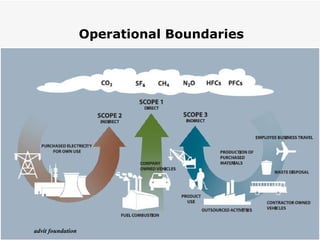

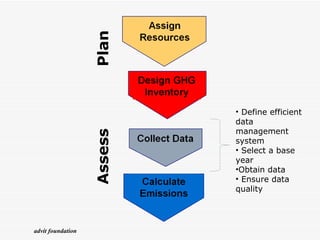

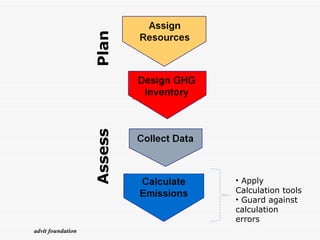

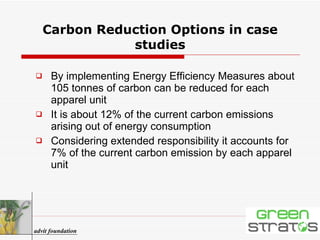

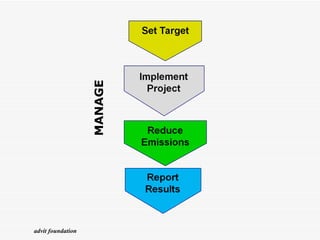

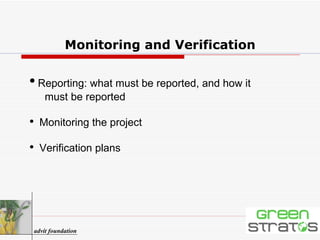

The document discusses strategies for mainstreaming energy efficiency and reducing carbon emissions in the Indian apparel industry. It provides an overview of baseline energy consumption and carbon emissions for a typical apparel manufacturing unit. Common energy efficiency measures are identified that could save on average 4.6 lakh units of electricity annually for each unit, reducing costs by 19 lakhs rupees annually after investing 40 lakhs rupees. Implementing energy efficiency and using an ESCO model could reduce carbon emissions from each unit by around 105 tonnes or 7% of current emissions annually. Monitoring and verification plans are needed to track performance and ensure savings.

![Base Line Energy Consumption Overall on an average about 5.6 lakh units of power is procured by each apparel unit. On an average about 1.2 lakh litres of diesel is being used. In monetary terms per manufacturing unit about Rs. 26 lakhs of power bill & Rs. 40 lakh rupees of diesel consumption. advit foundation Samit Jain [email_address]](https://image.slidesharecdn.com/advitfoundation-energyefficiency-100701035922-phpapp01/85/Advit-Foundation-Energy-Efficiency-6-320.jpg)

![Advit Foundation 610A, Udyog Vihar, Phase V Gurgaon, Haryana Email: [email_address] www.advit.org THANK YOU advit foundation](https://image.slidesharecdn.com/advitfoundation-energyefficiency-100701035922-phpapp01/85/Advit-Foundation-Energy-Efficiency-38-320.jpg)