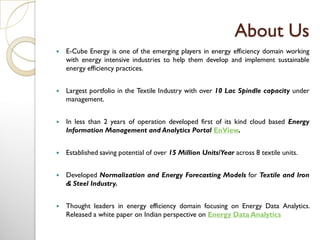

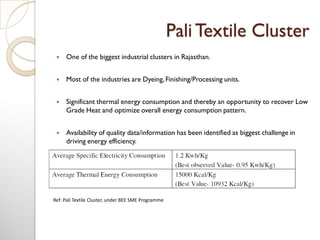

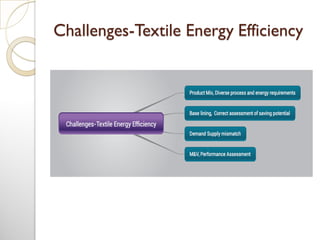

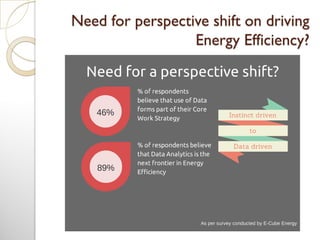

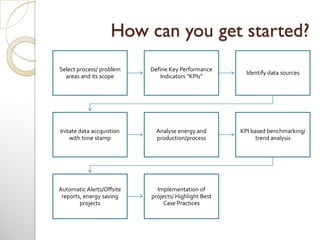

This document discusses how data analytics can help foster energy efficiency, specifically in the textile industry. It provides examples of how E-Cube Energy has used data analytics to optimize processes, normalize energy usage based on production and establish energy savings baselines. Key points made include:

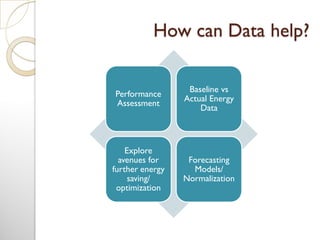

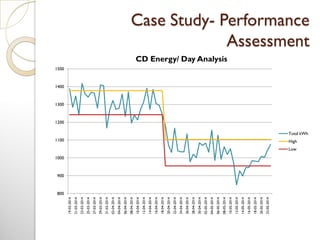

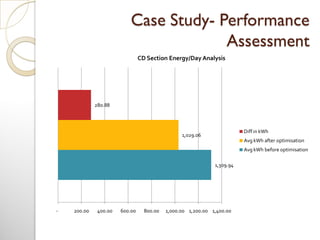

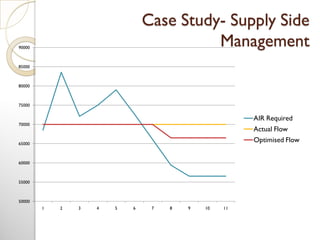

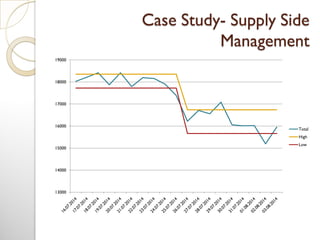

- E-Cube has established 15 million units/year in energy savings across textile clients through performance assessment, forecasting models and supply side optimization.

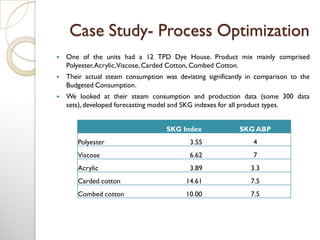

- Case studies show how analyzing steam consumption and production data helped optimize a dyeing process and attribute savings to specific factors like product mix changes.

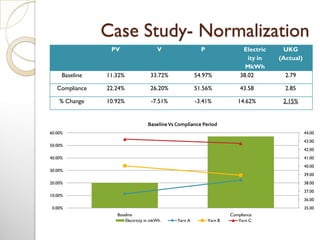

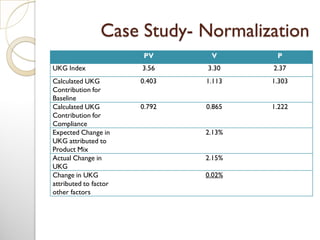

- Normalizing energy usage based on production helped verify over 2% savings from optimization projects at one textile mill.

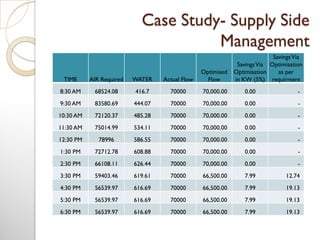

- Analyzing water and air