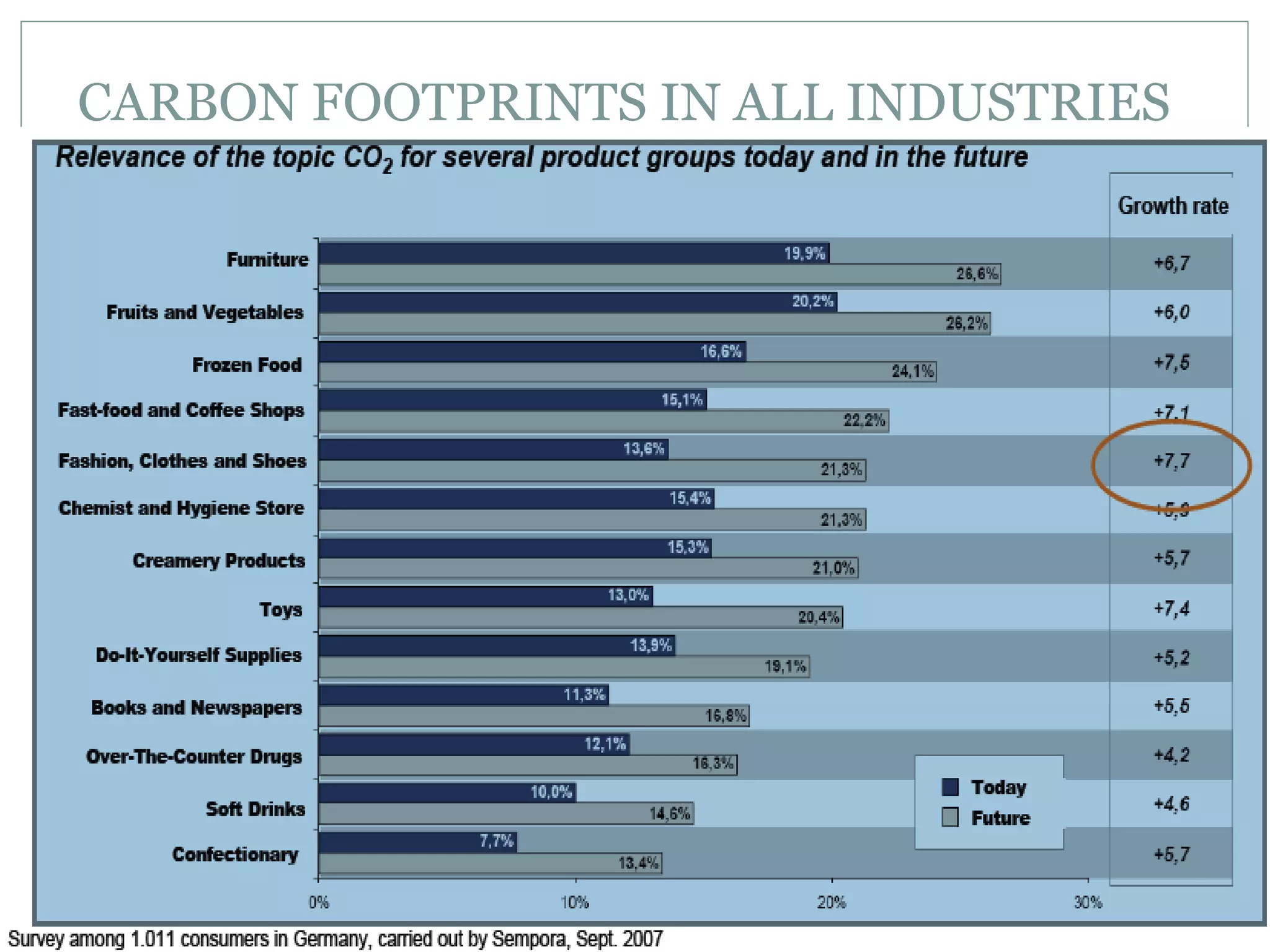

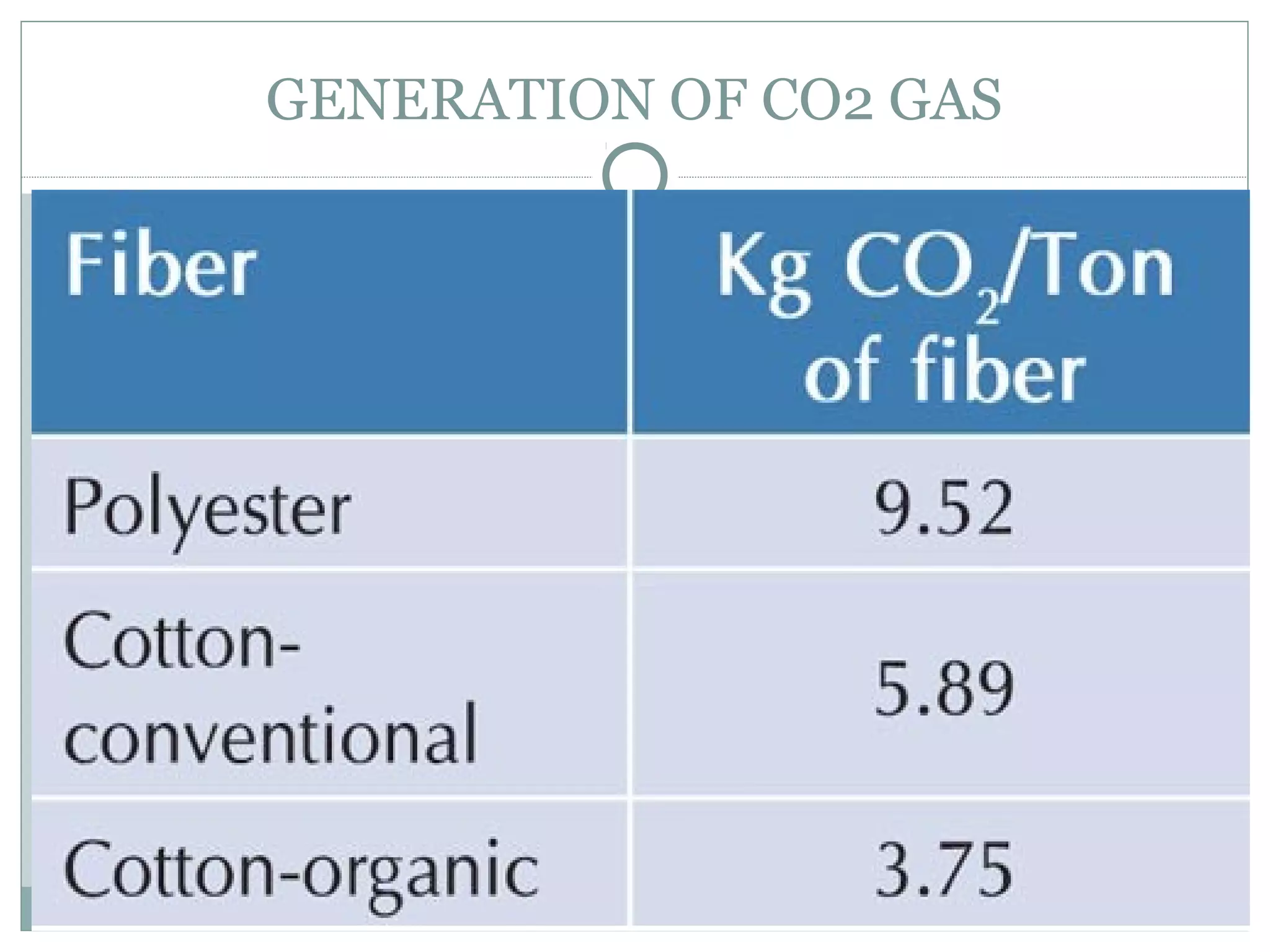

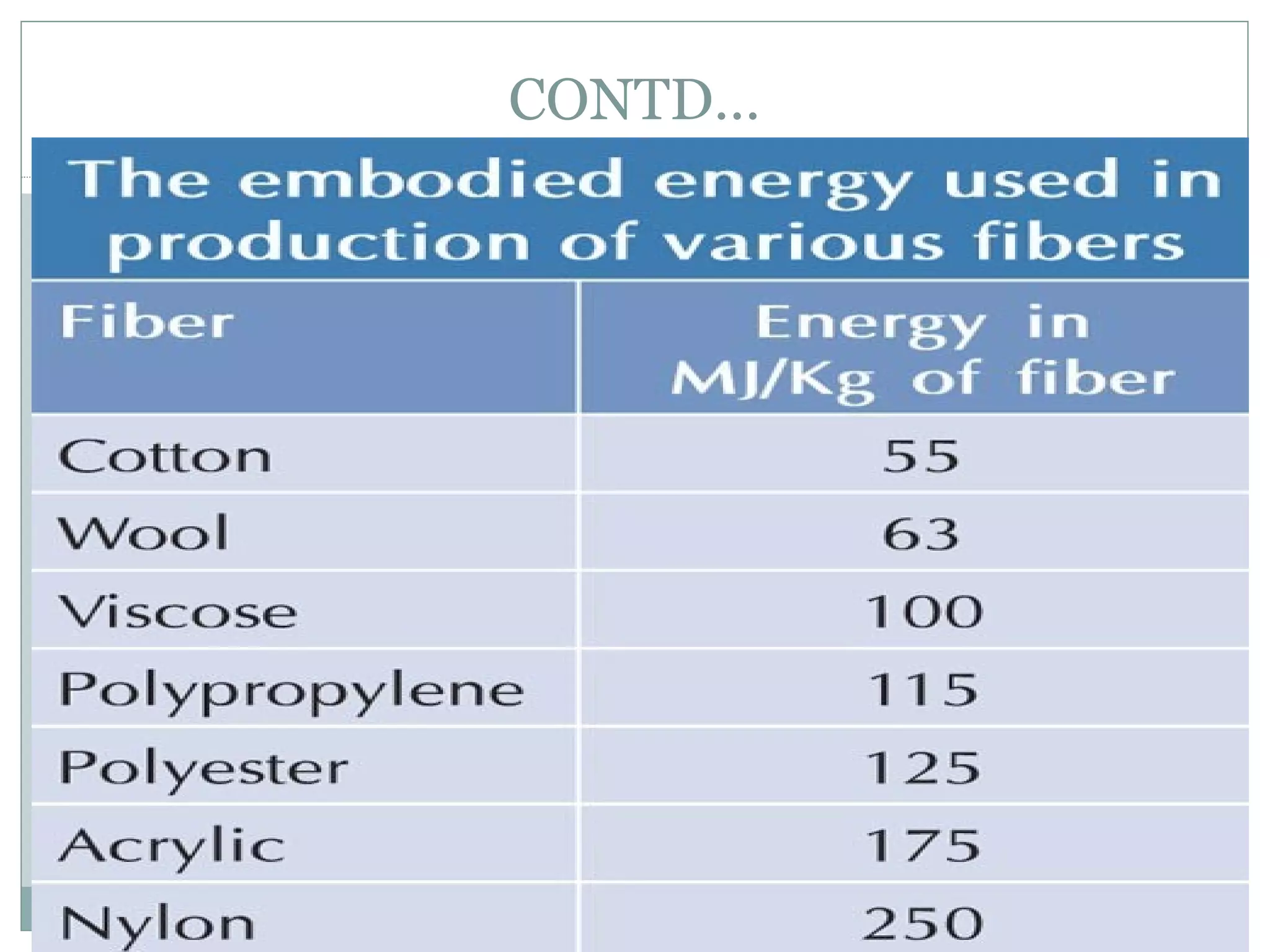

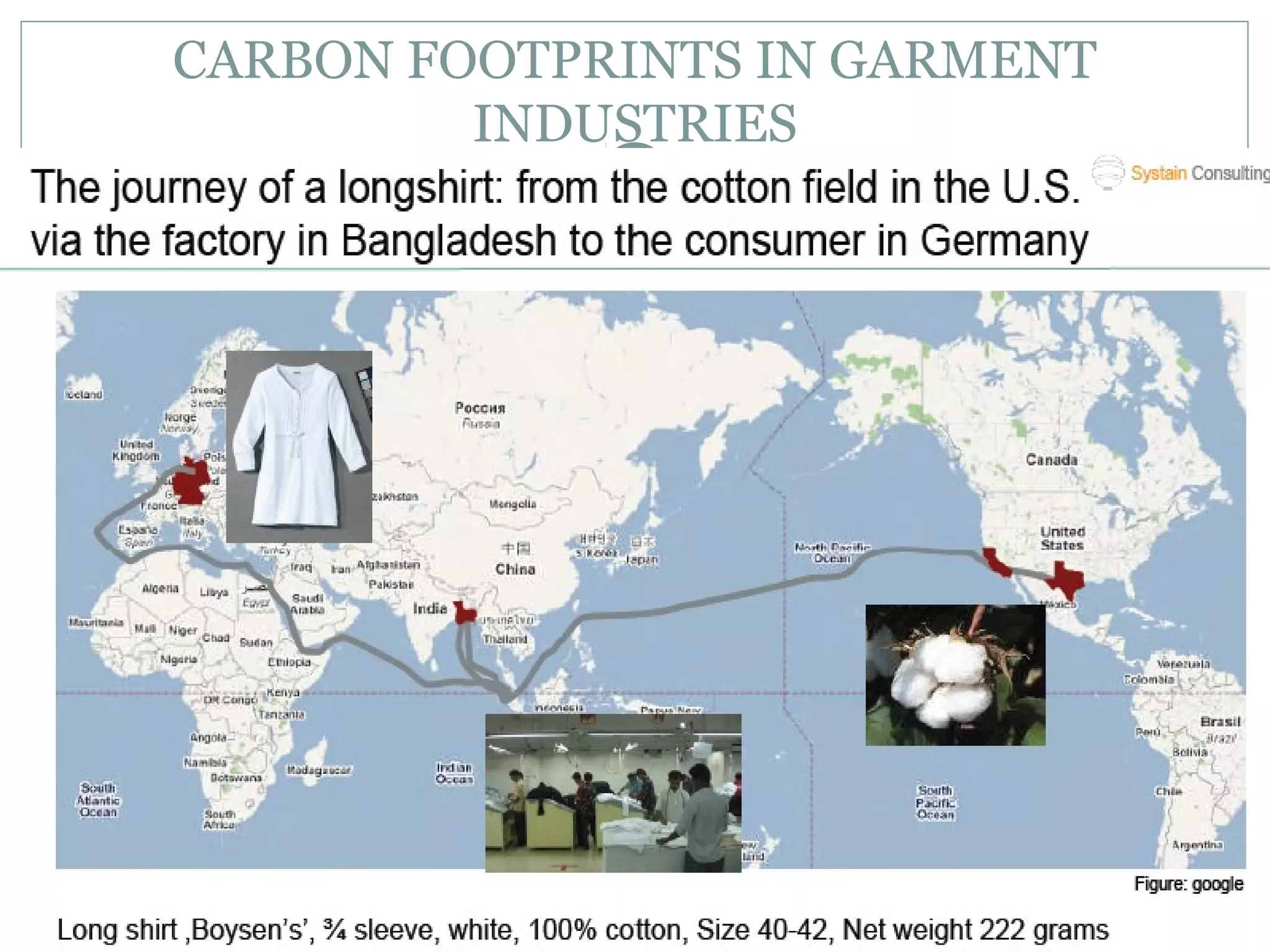

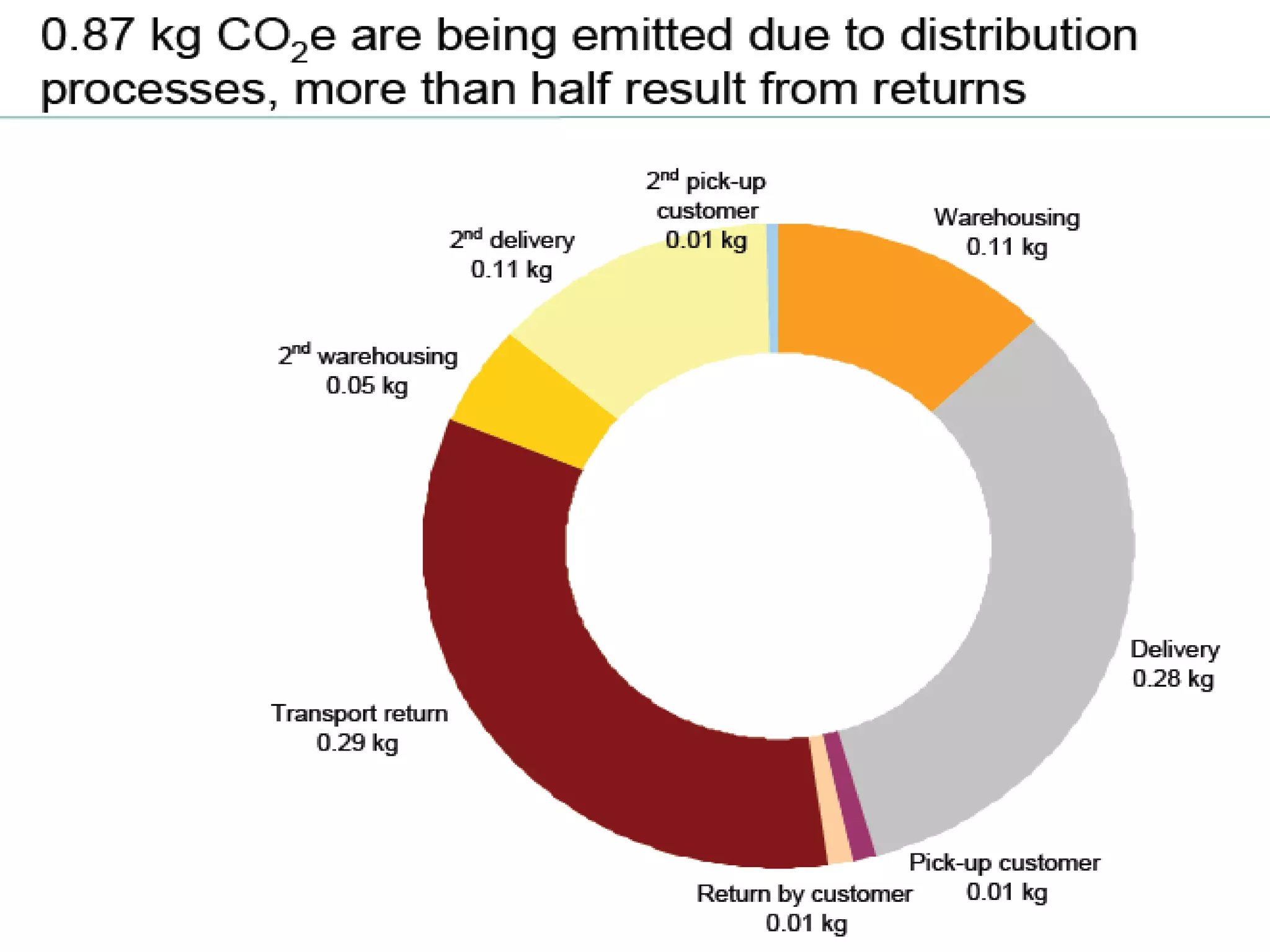

The document discusses carbon footprints in the textile industry. It defines carbon footprint as the total greenhouse gas emissions caused by an organization, product, or activity. The textile industry has a large carbon footprint due to the energy and resources required for production. Calculating carbon footprints involves quantifying direct emissions from energy use as well as indirect emissions from a product's entire lifecycle. Reducing the textile industry's carbon footprint can be achieved through methods like using renewable energy sources, modernizing equipment, optimizing processes, and utilizing sustainable materials. Measuring and lowering carbon footprints is important for the textile industry to reduce its environmental impact.