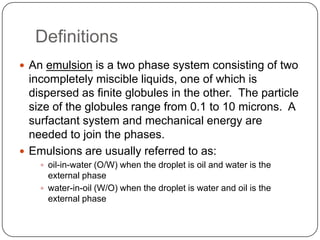

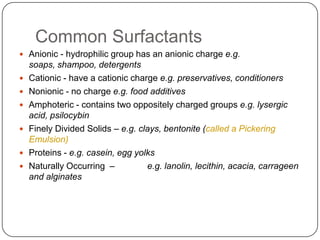

Emulsions are thermodynamically unstable mixtures of two immiscible liquids where one liquid is dispersed as globules in the other with the help of an emulsifying agent. They can be oil-in-water or water-in-oil emulsions. Surfactants are needed to form and stabilize emulsions by reducing interfacial tension at the droplet surface. Emulsions will eventually separate or "break" as nature seeks to minimize free energy by reducing interfacial area between the liquids. Temperature, processing methods, and ingredients can all impact emulsion stability over time.