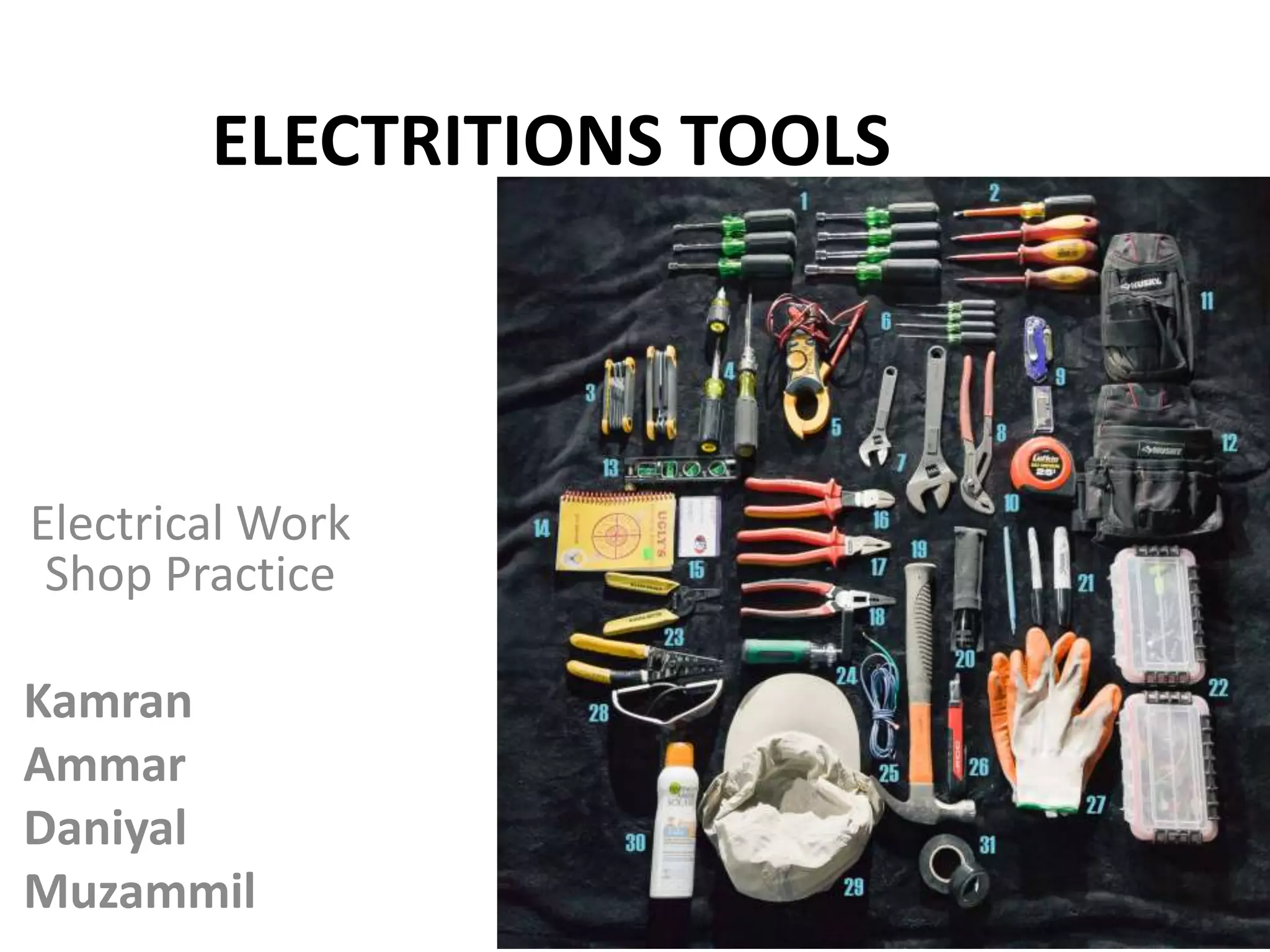

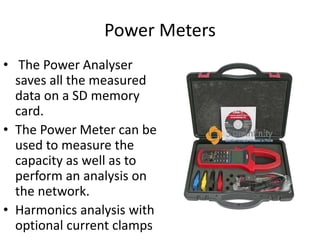

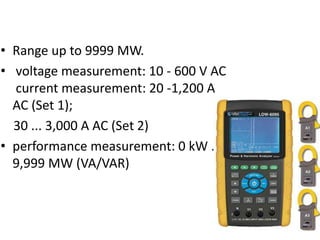

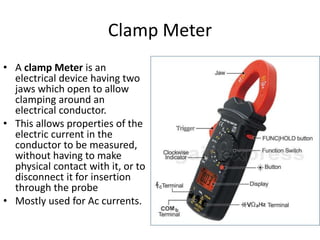

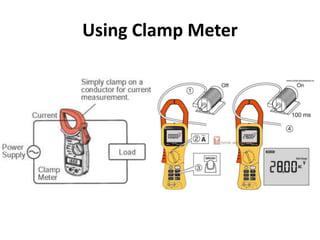

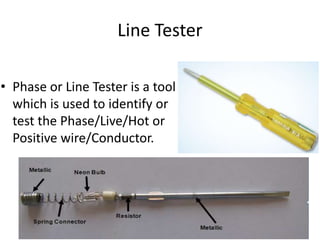

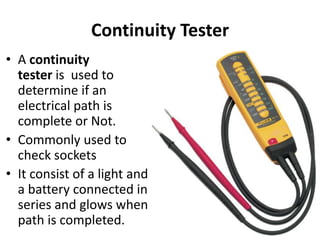

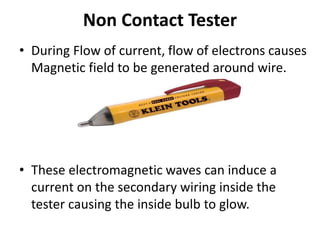

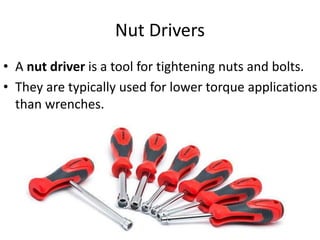

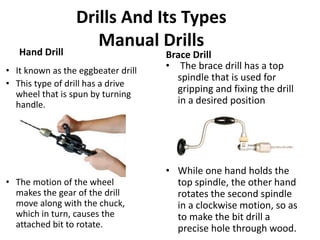

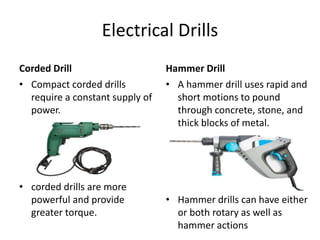

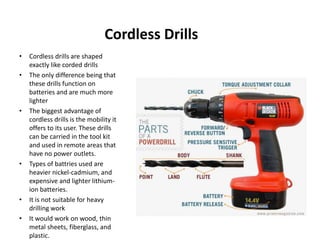

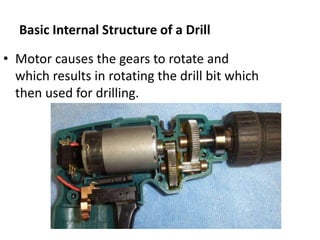

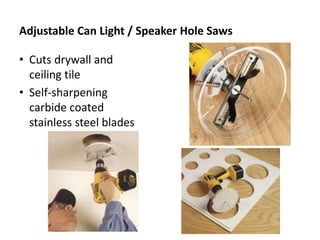

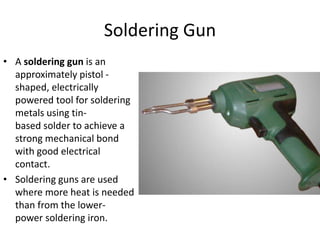

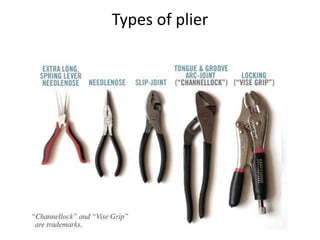

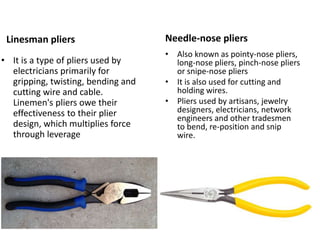

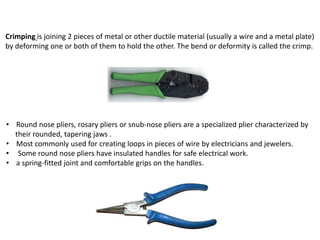

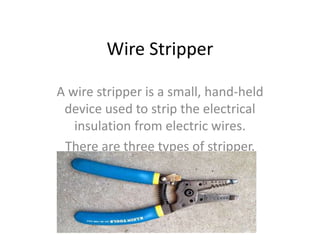

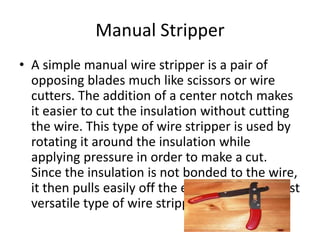

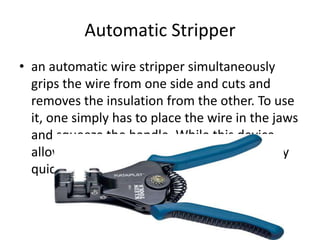

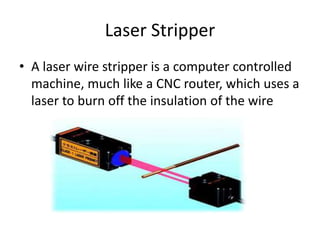

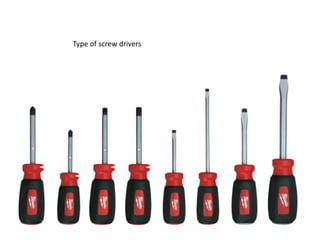

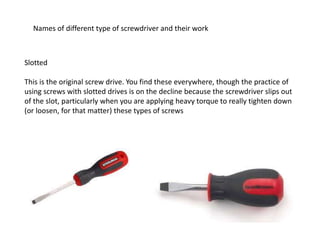

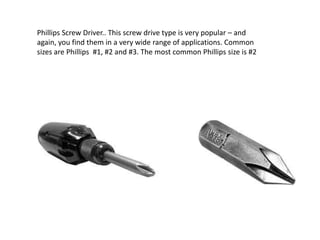

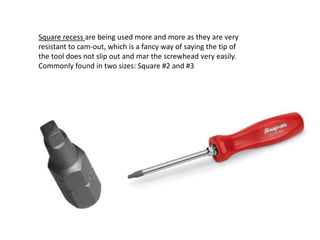

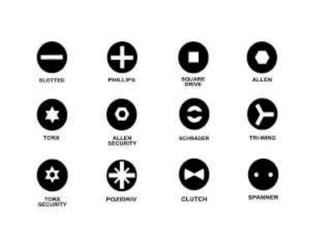

This document provides information about various electrical tools used in electrical work. It describes power meters that can measure voltage, current, power, and perform harmonics analysis. It also discusses clamp meters that measure current in a conductor without contact, line testers to identify live wires, and continuity testers to check circuits. Additionally, it covers nut drivers, manual drills, electric drills like corded drills and cordless drills, hole saws, soldering irons and guns, and various types of pliers, wire strippers, screwdrivers and their uses. It also gives safety tips about maintaining tools properly, using the right PPE, and electrical hazards.