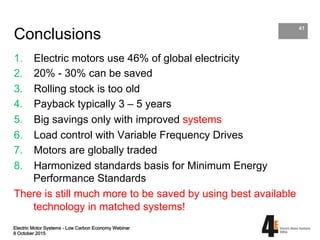

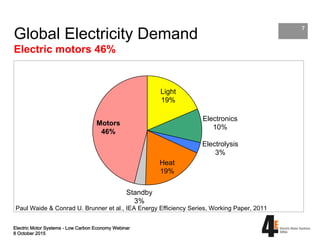

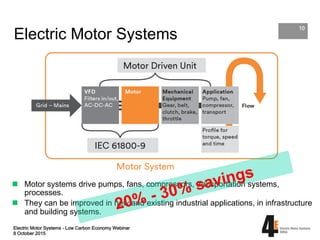

The document outlines a webinar discussing electric motor systems and their efficiency improvements, emphasizing the potential for 20% to 30% energy savings. It covers standards, policies, and steps for optimizing motor systems in industrial applications, along with successful programs and tools available for users. Key takeaways include the significant electricity consumption by electric motors, the importance of harmonized global standards, and the need for system improvements and load control through variable frequency drives.

![35

Electric Motor Systems - Low Carbon

Economy Webinar 8 October 2015

Calculations

Effective consumption of electricity of the electrical drives 9.707 [GWh/a]

Fraction of effective consumption of electricity of electrical 69.3 [%]

Percentage of motors to be replaced 64.0 [%]

Numbers of motors with VFD 40.0 [%]

Improved consumption of electricity of the electrical drives 8.238 [GWh/a]

Potential of energy efficiency (electric energy) 1.469 [GWh/a]

Potential of energy efficiency (in currency) 0.157 [Mio CHF/a]

Potential of energy efficiency (in percentage) 15.1 [%]

Additional investments for realisation of the potential of

energy efficiency

0.205 [Mio CHF]

Payback-time for realisation of efficiency potential 1.3 [a]

0.177493766

1.45

Release 1

Copyright ©: topmotors 2010

9.707

8.238

1.469

0.000

2.000

4.000

6.000

8.000

10.000

12.000

Effective consumption of electricity of

the electrical drives

Improved consumption of electricity of

the electrical drives

Potential of energy efficiency (electric

energy)

1

3

2

4

SOTEA Efficiency Potential ILI Intelligent List

STR Standard Test Report MST Motor Systems Tool](https://image.slidesharecdn.com/webinarmsvanwerkhoven20151008-170116190850/85/Electric-Motor-Systems-targeting-and-implementing-efficiency-improvements-35-320.jpg)

![36Package of measures

Life Cycle: 10 – 20 years Payback: Package 2.4 years

0

200

400

600

800

1,000

1,200

1,400

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

532

555

600

601

364

575B

490

320

289

374B

362

374A

428

374C

514A

520A

405

494B

363

425A

374E

463A

293

389B

575C

425B

508

156

520D

514B

520B

463B

453D

453A

494A

520C

575A

555V

184

Electricenergysavings[MWh/a]

Payback[years]

Machine identification number

Machine factory

Pay back

Pay back (cumulated)

Energy savings (right scale)

Electric Motor Systems - Low Carbon Economy Webinar

8 October 2015](https://image.slidesharecdn.com/webinarmsvanwerkhoven20151008-170116190850/85/Electric-Motor-Systems-targeting-and-implementing-efficiency-improvements-36-320.jpg)