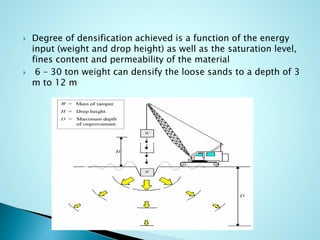

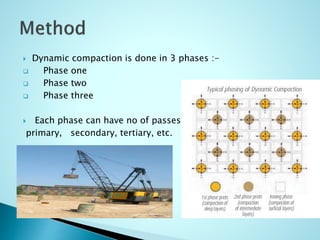

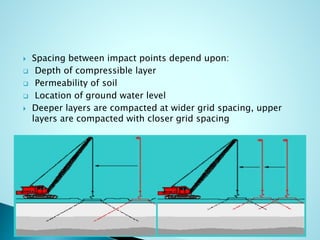

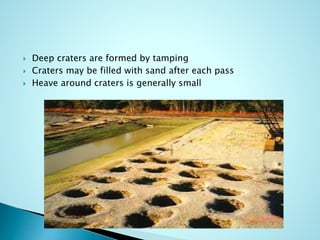

Dynamic compaction is a technique developed in the 1960s that involves repeatedly dropping a large weight from a crane onto the ground to compact soils for construction projects like roads, airports, and buildings. The weight can range from 6 to 172 tons and is dropped from heights of 10 to 40 meters to densify soils to depths of 3 to 12 meters depending on the weight and soil properties. It is conducted in multiple phases with progressively closer spacing of impacts and is effective on both saturated and dry granular soils for reclamation projects with variable soil conditions.