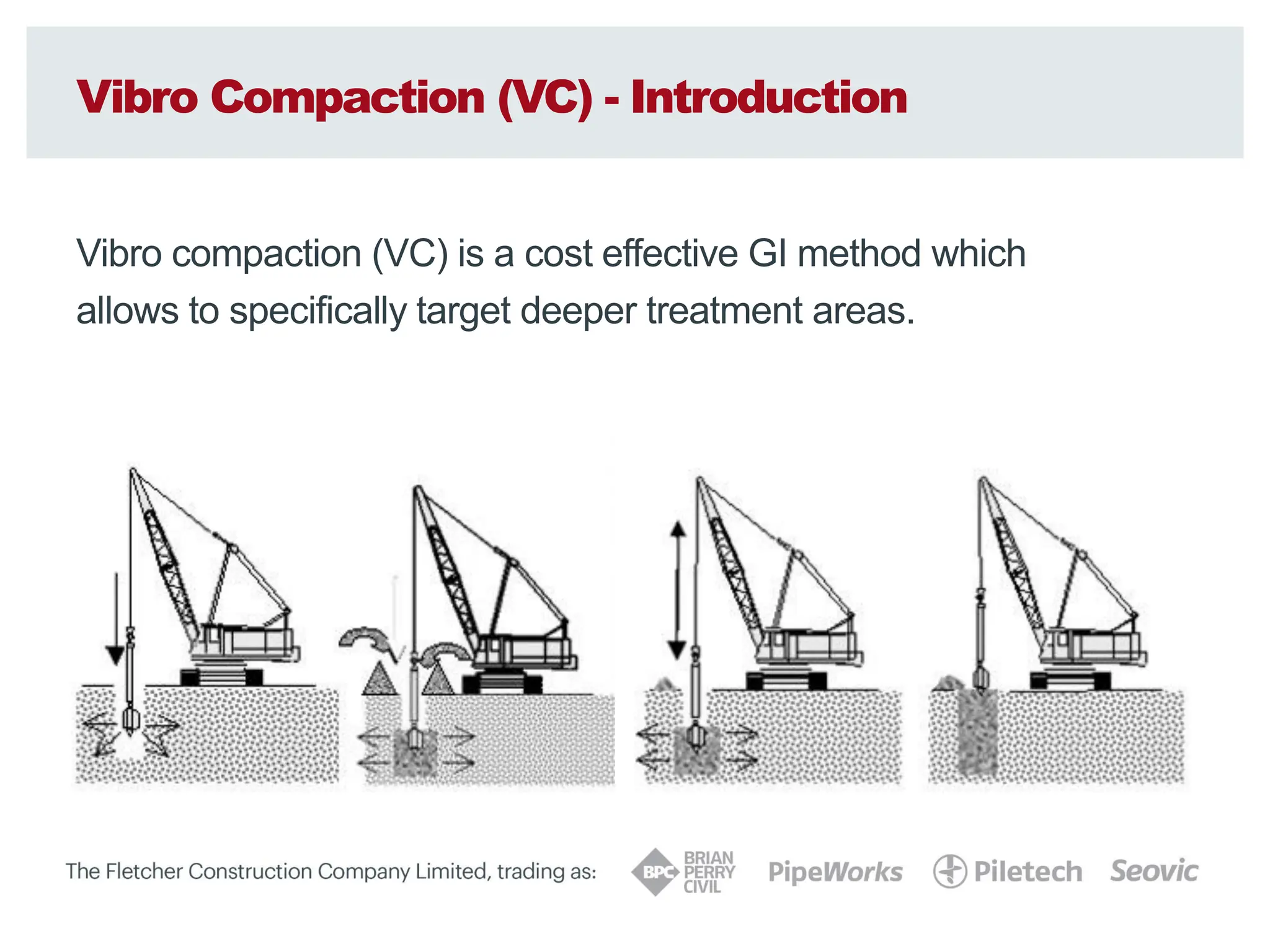

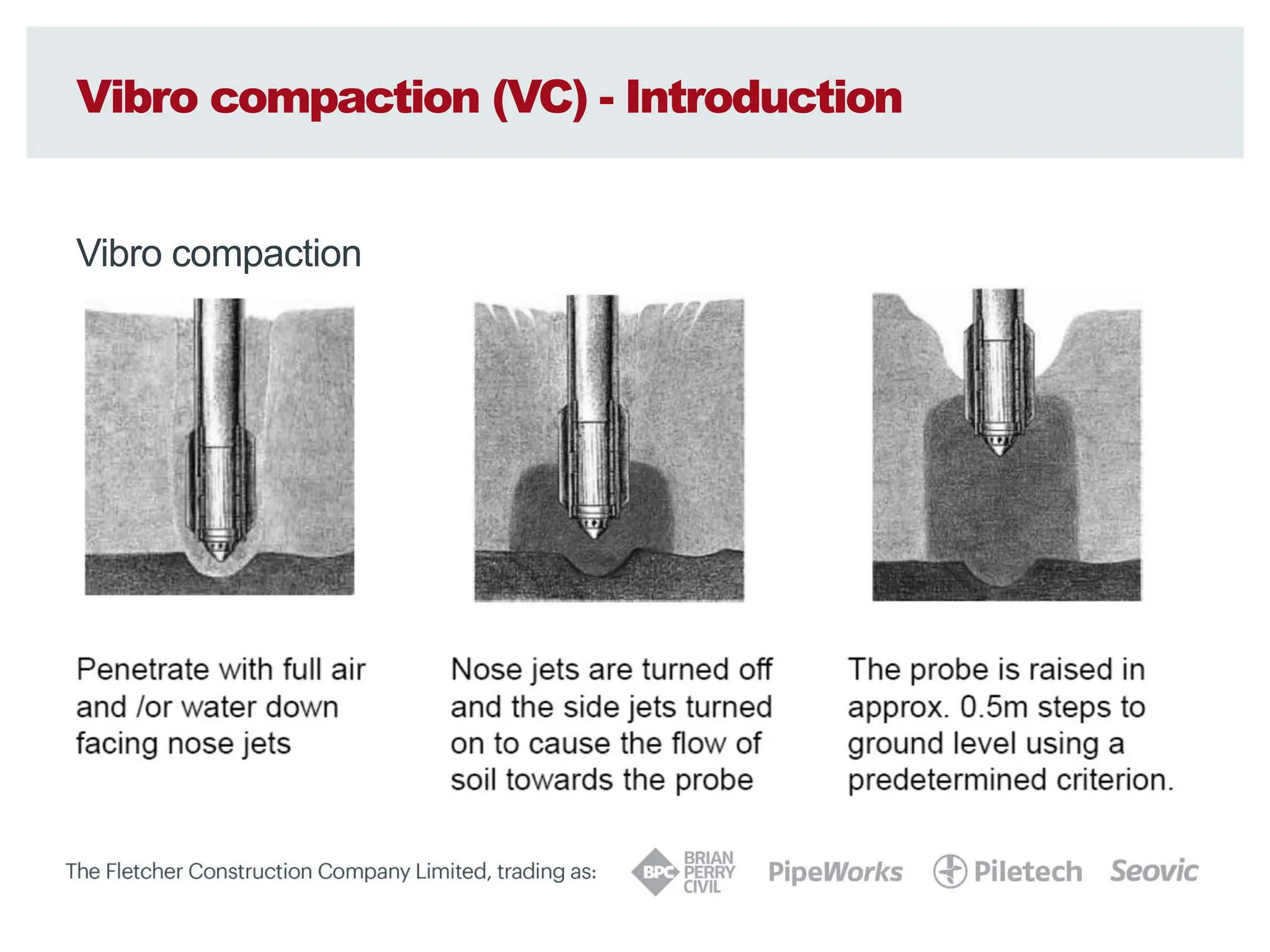

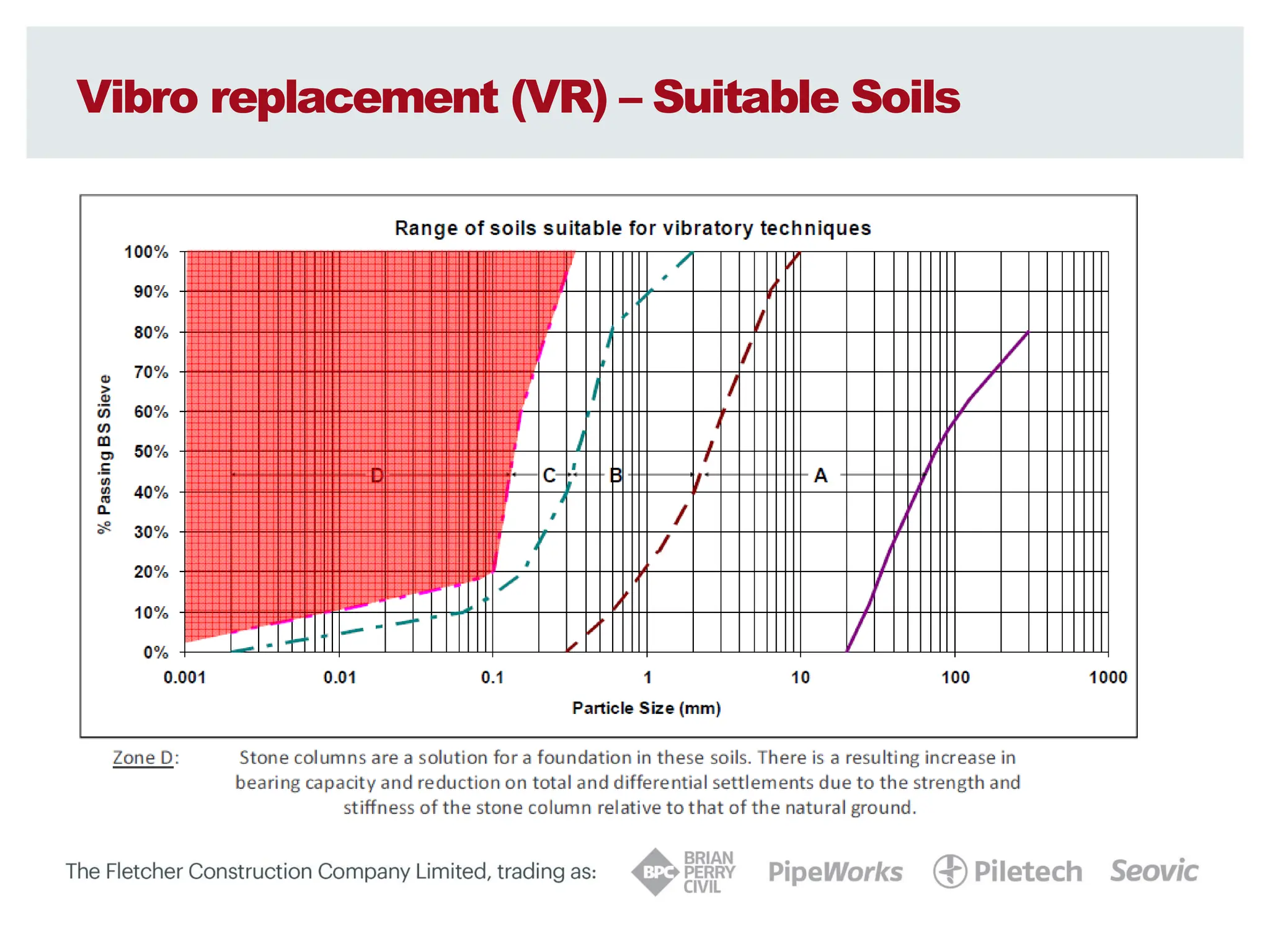

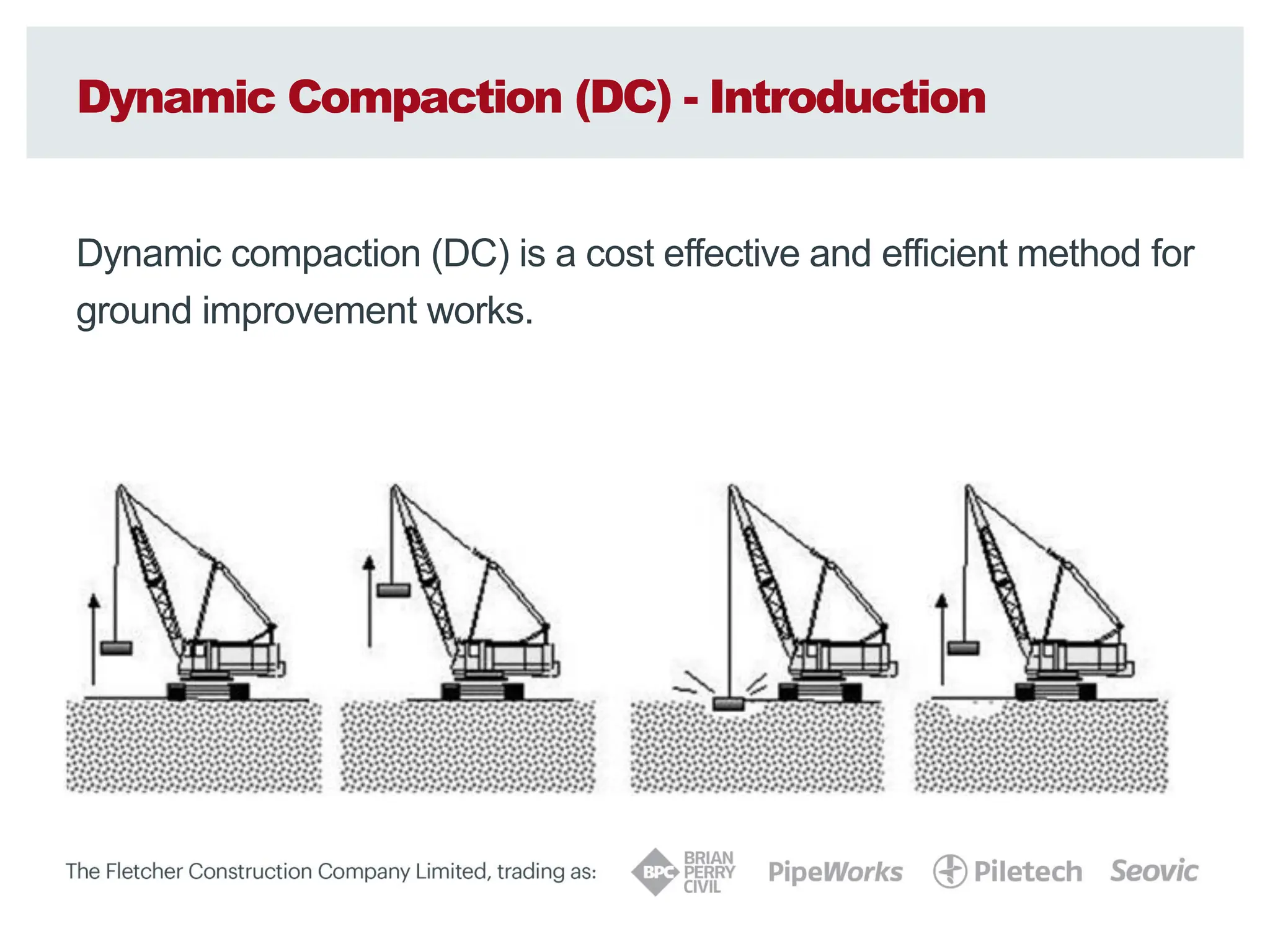

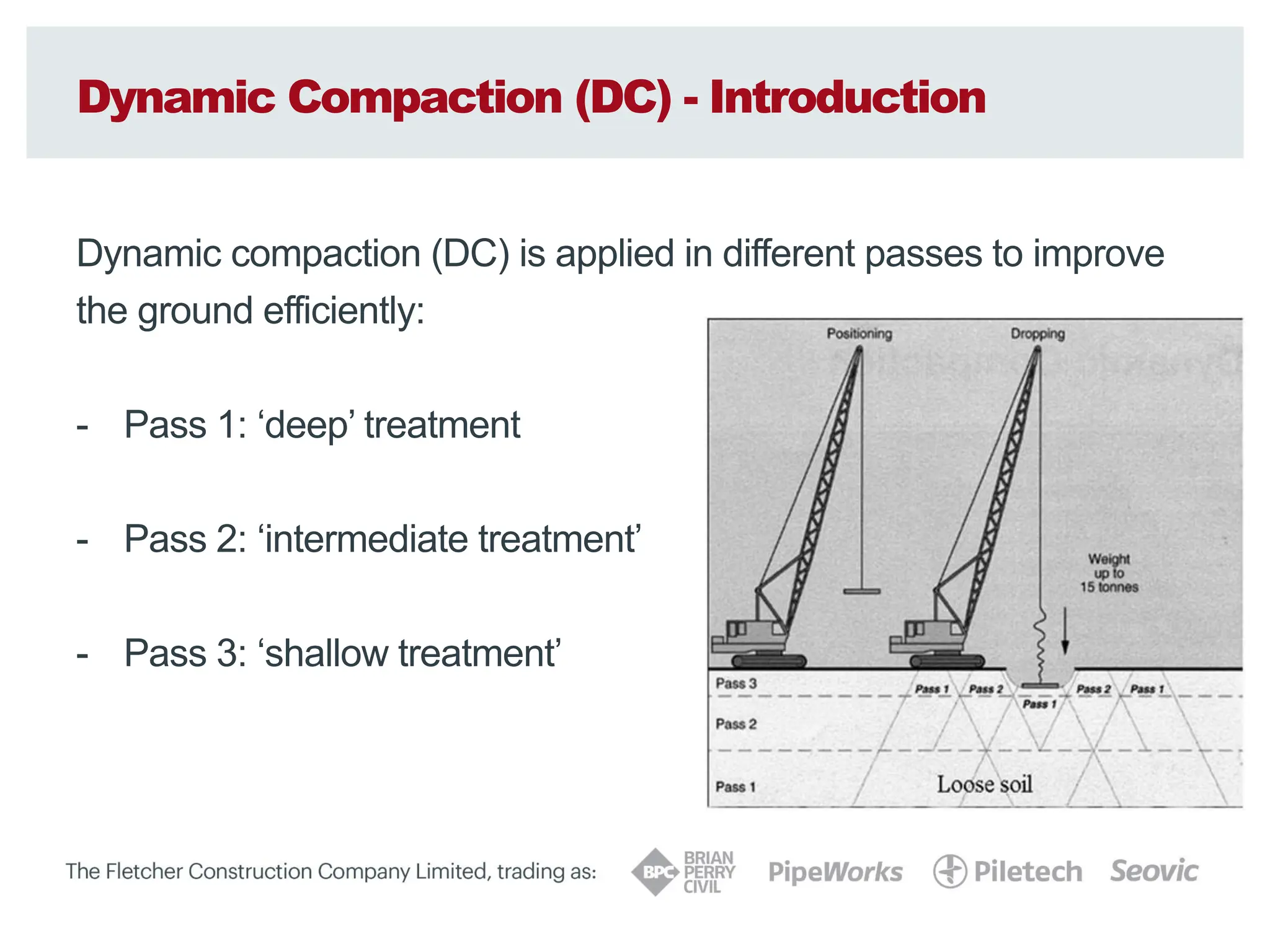

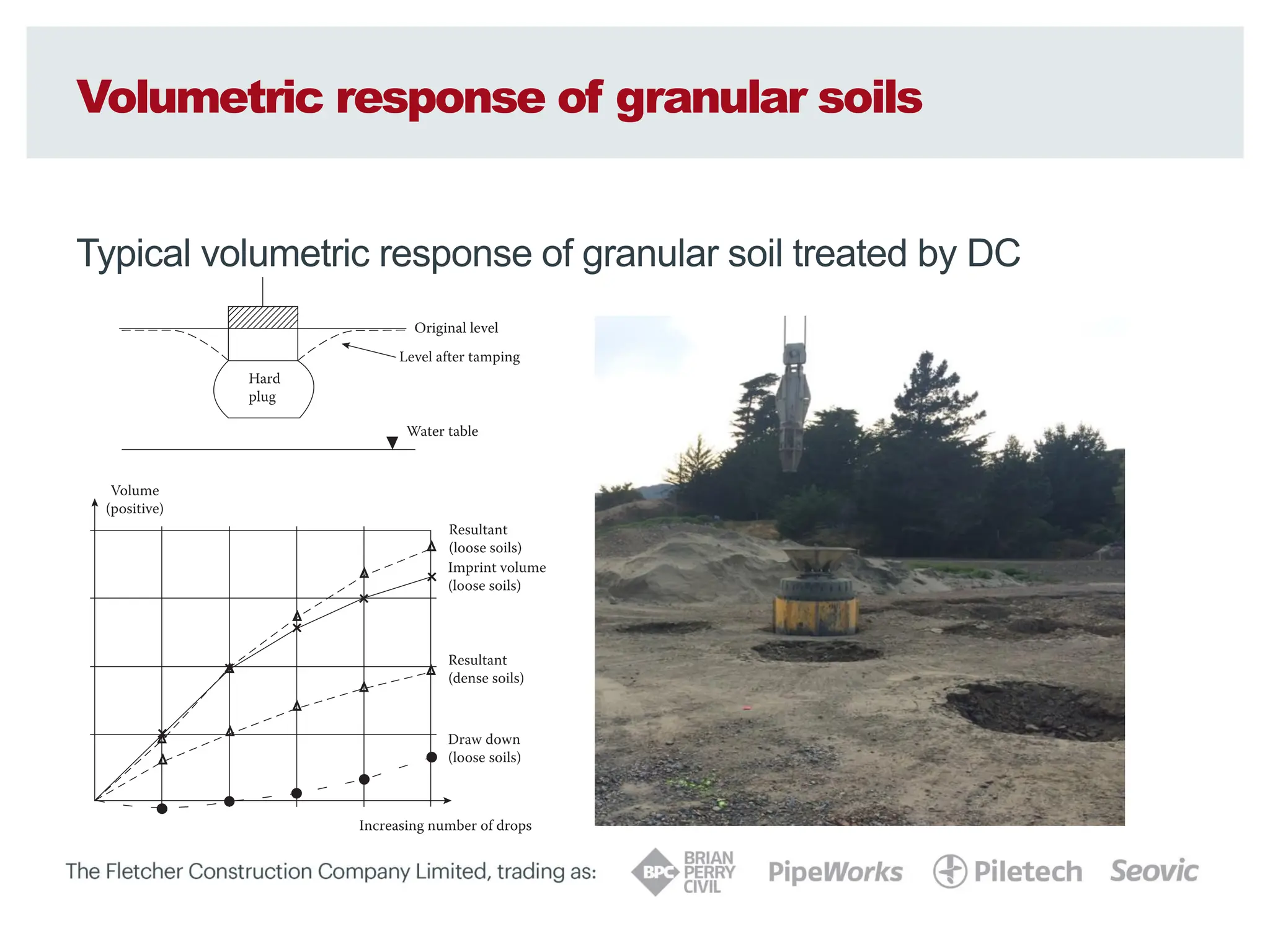

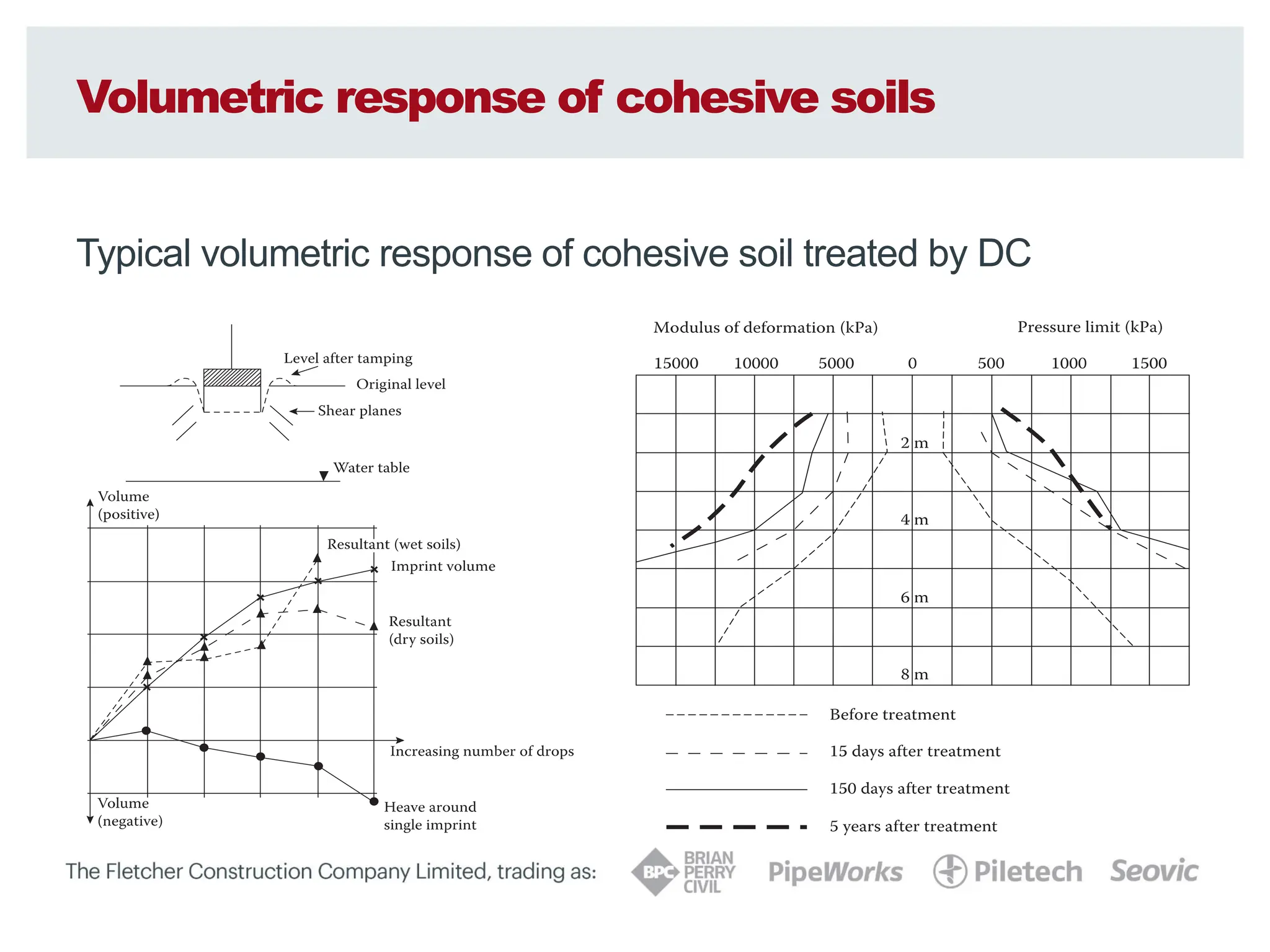

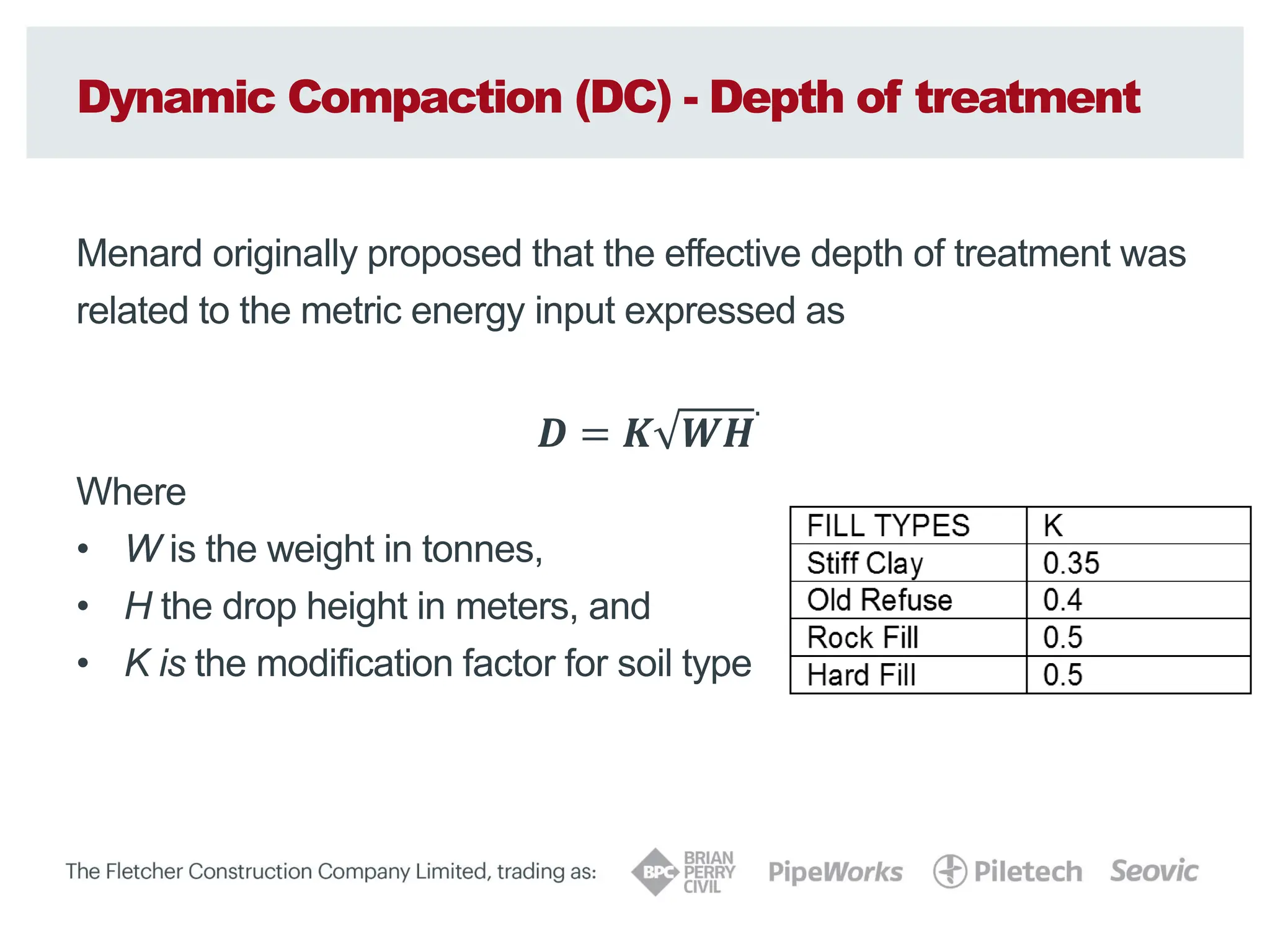

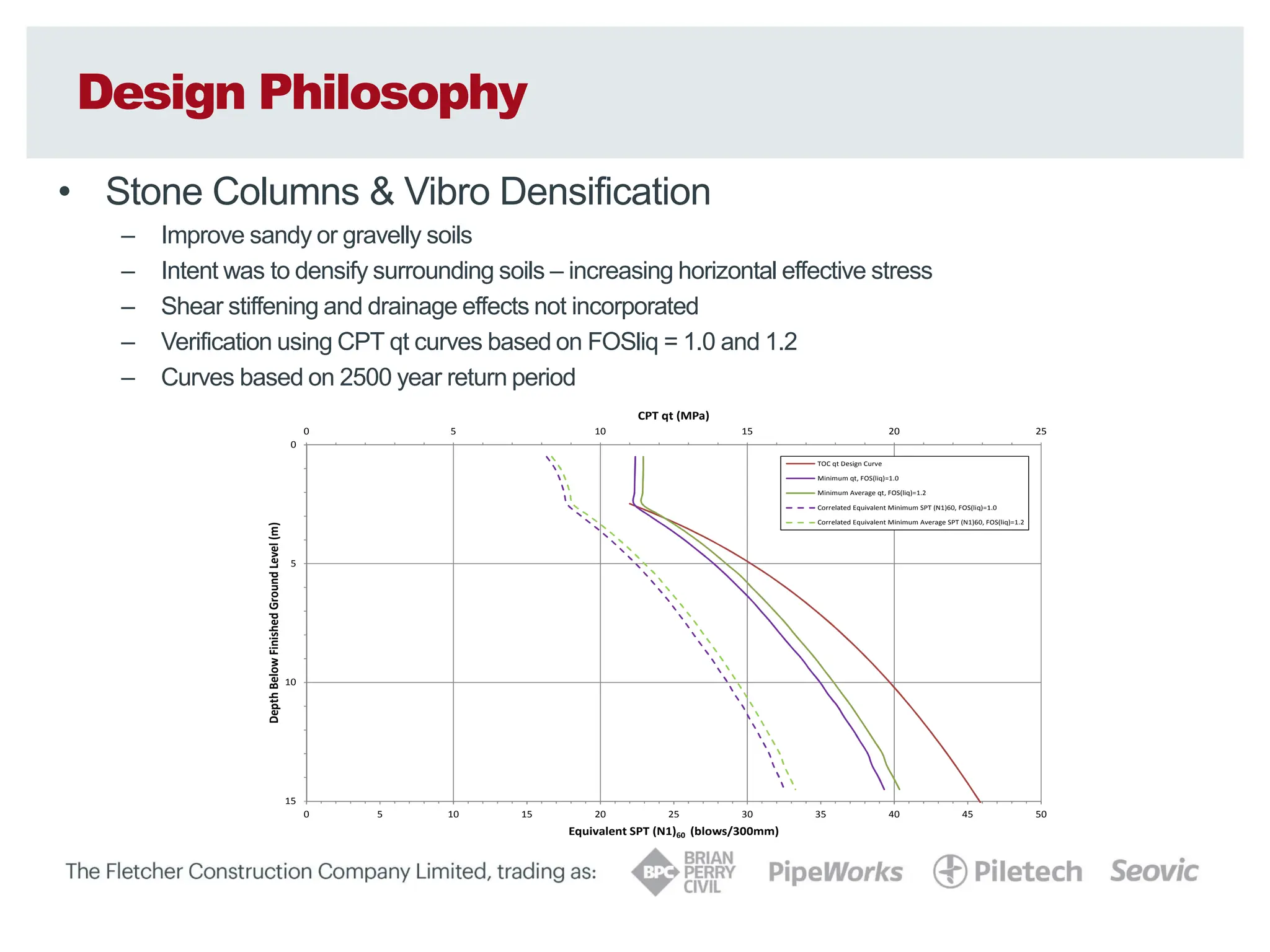

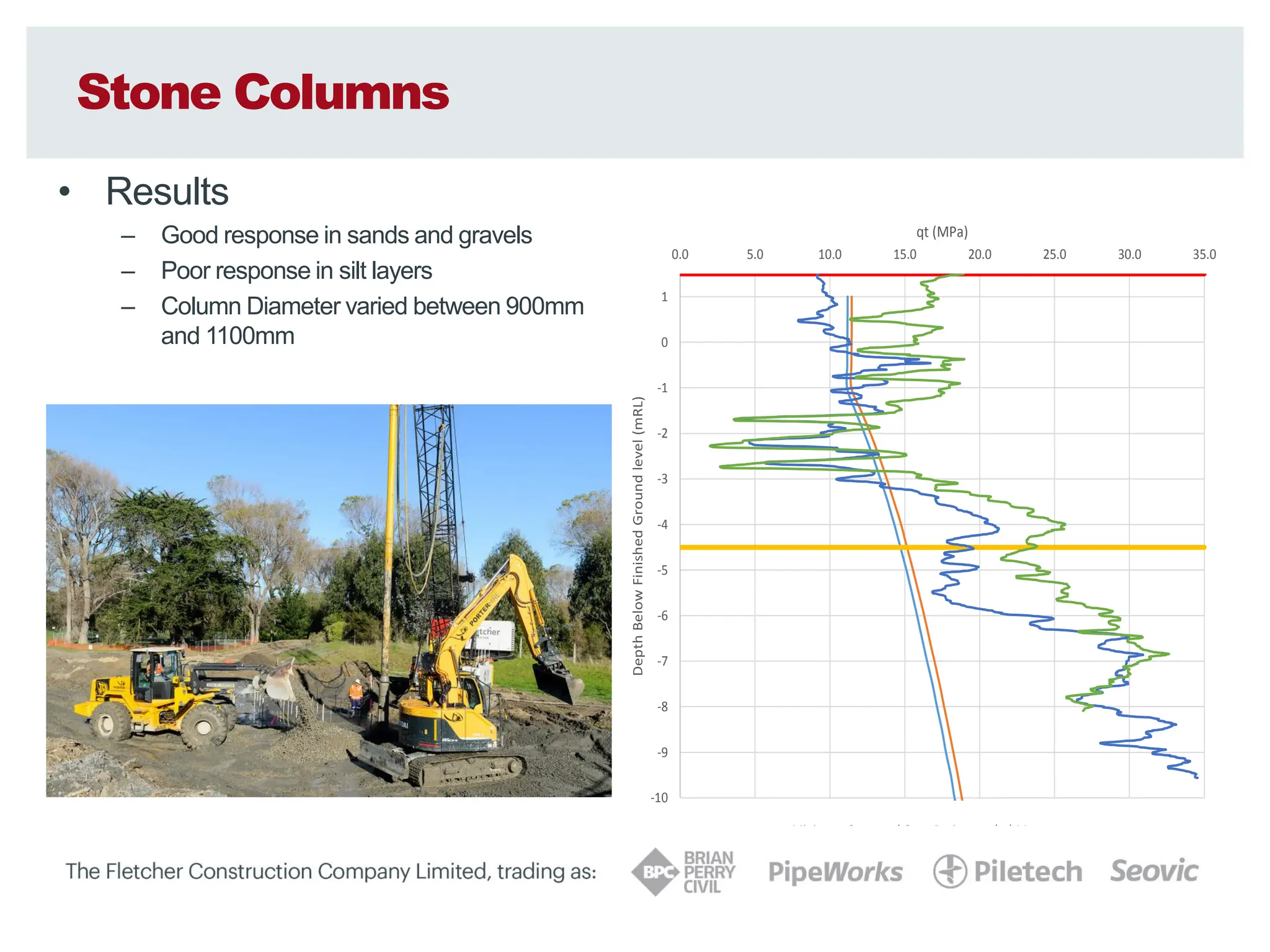

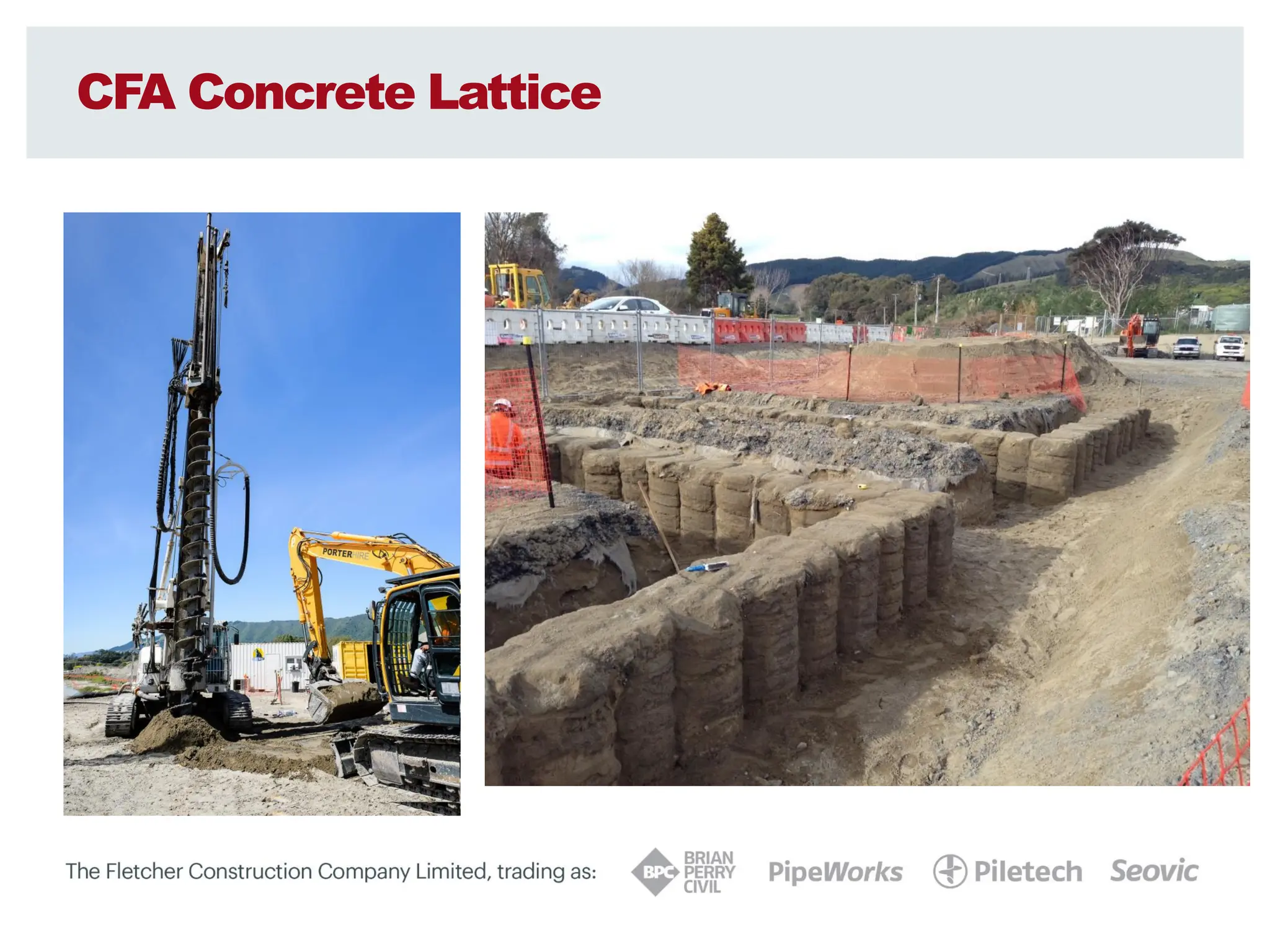

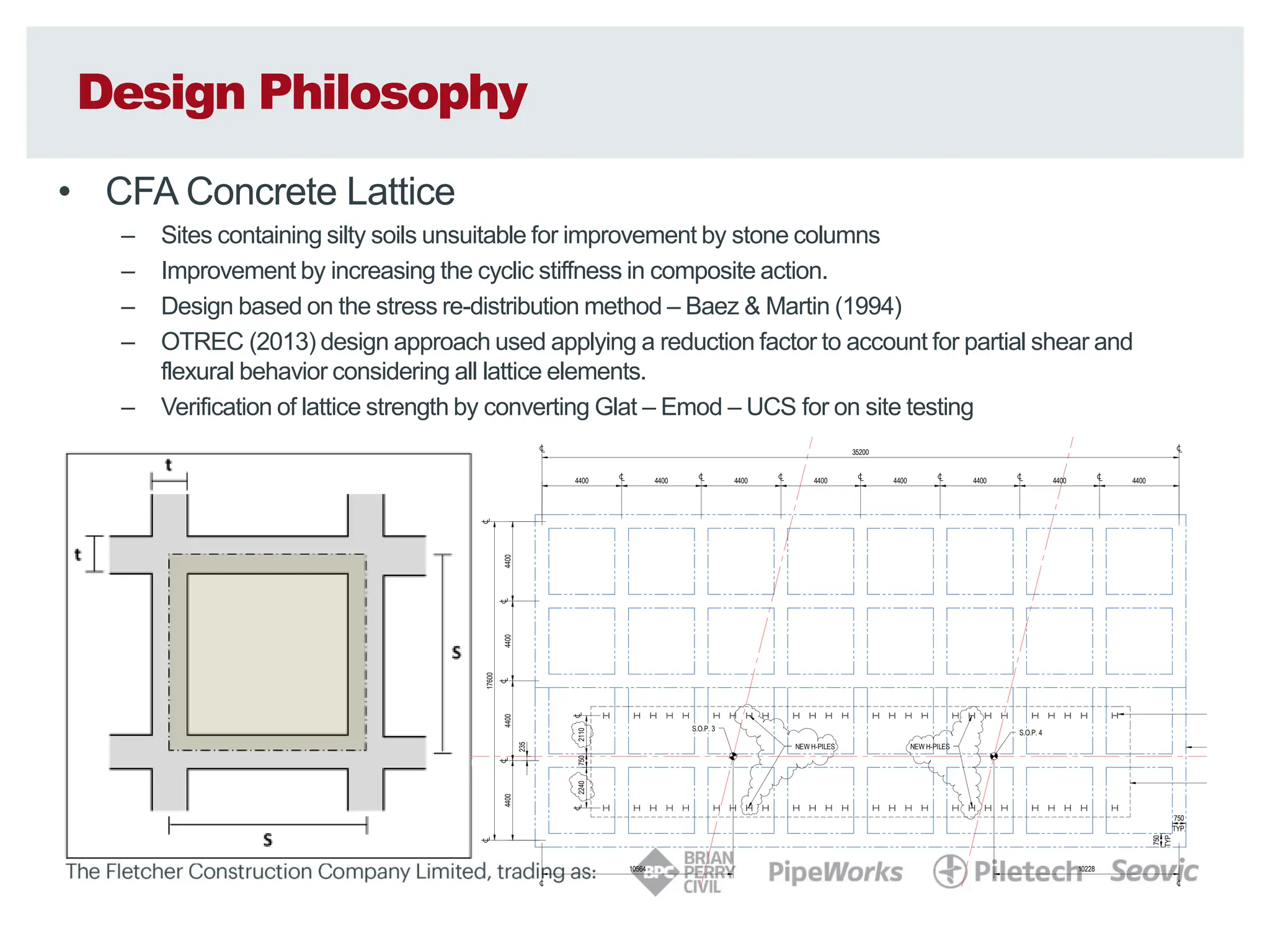

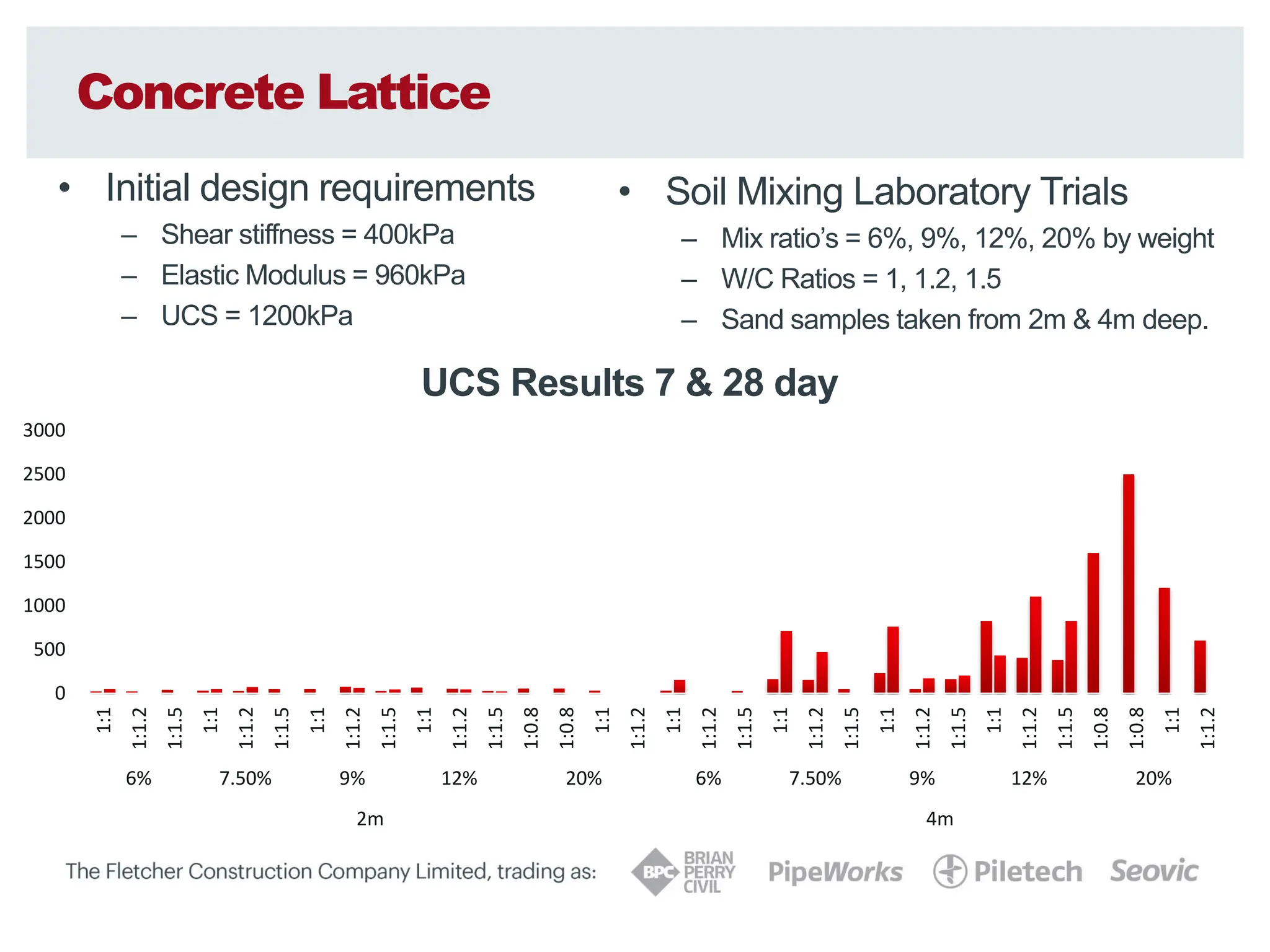

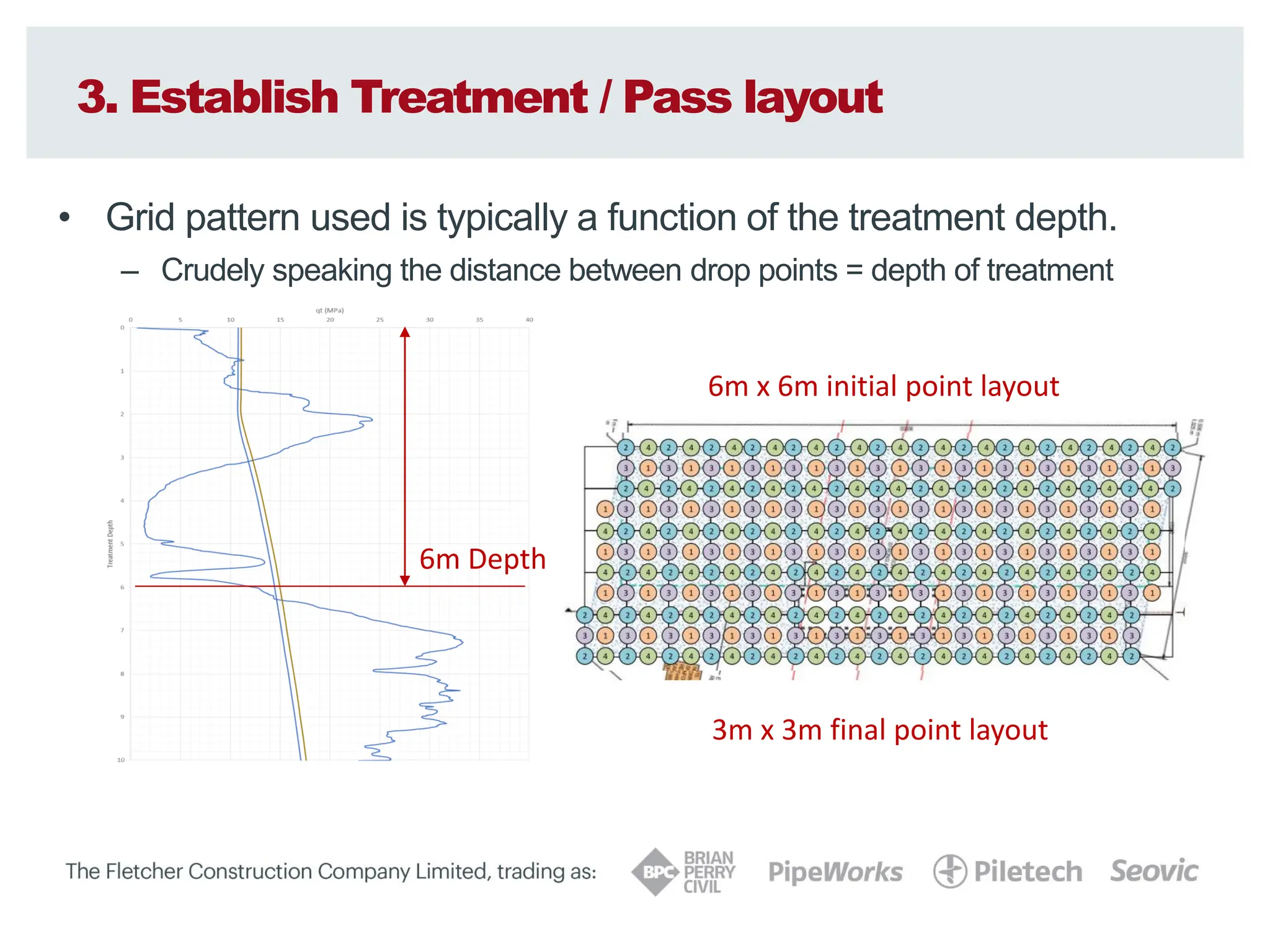

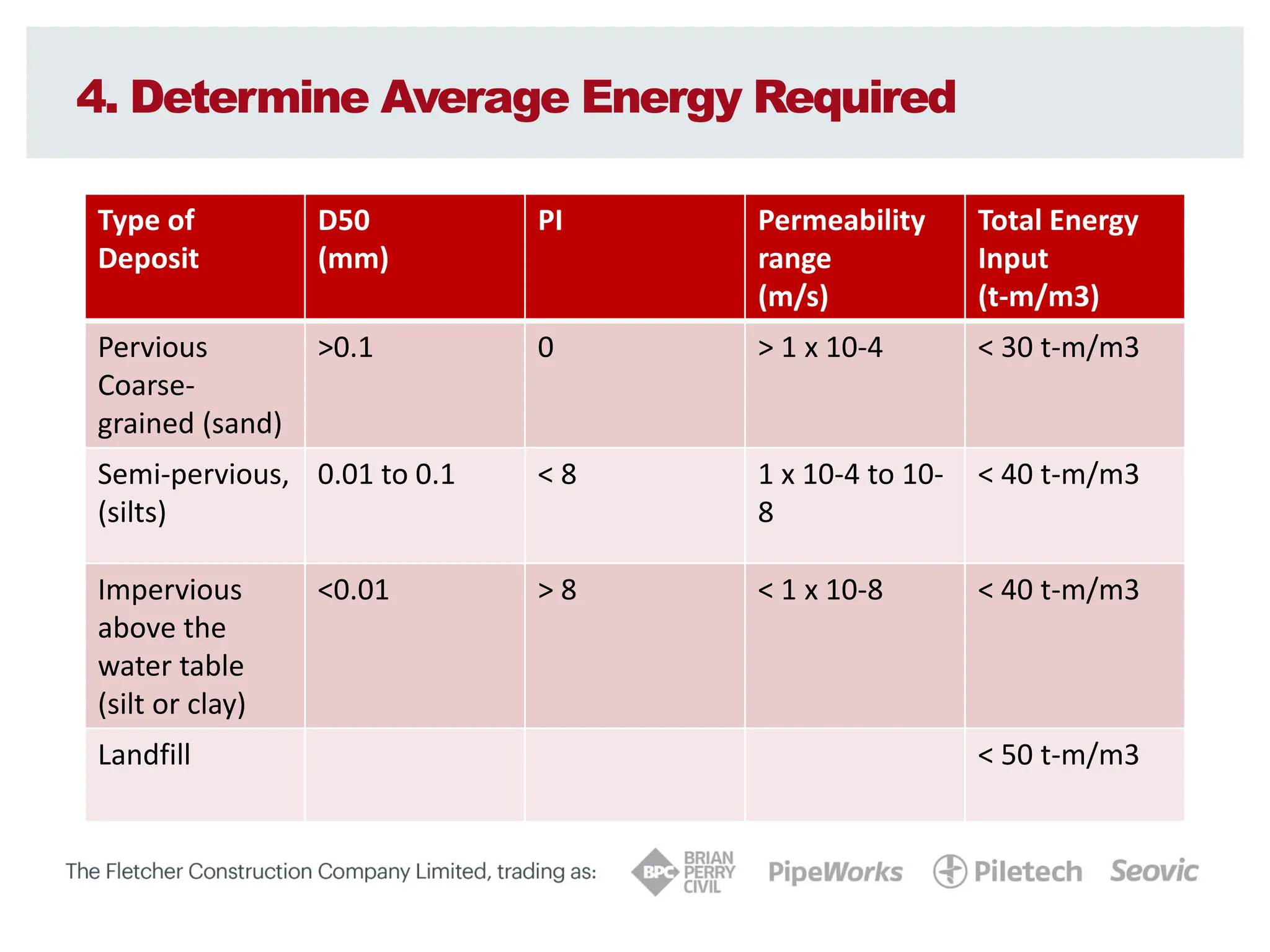

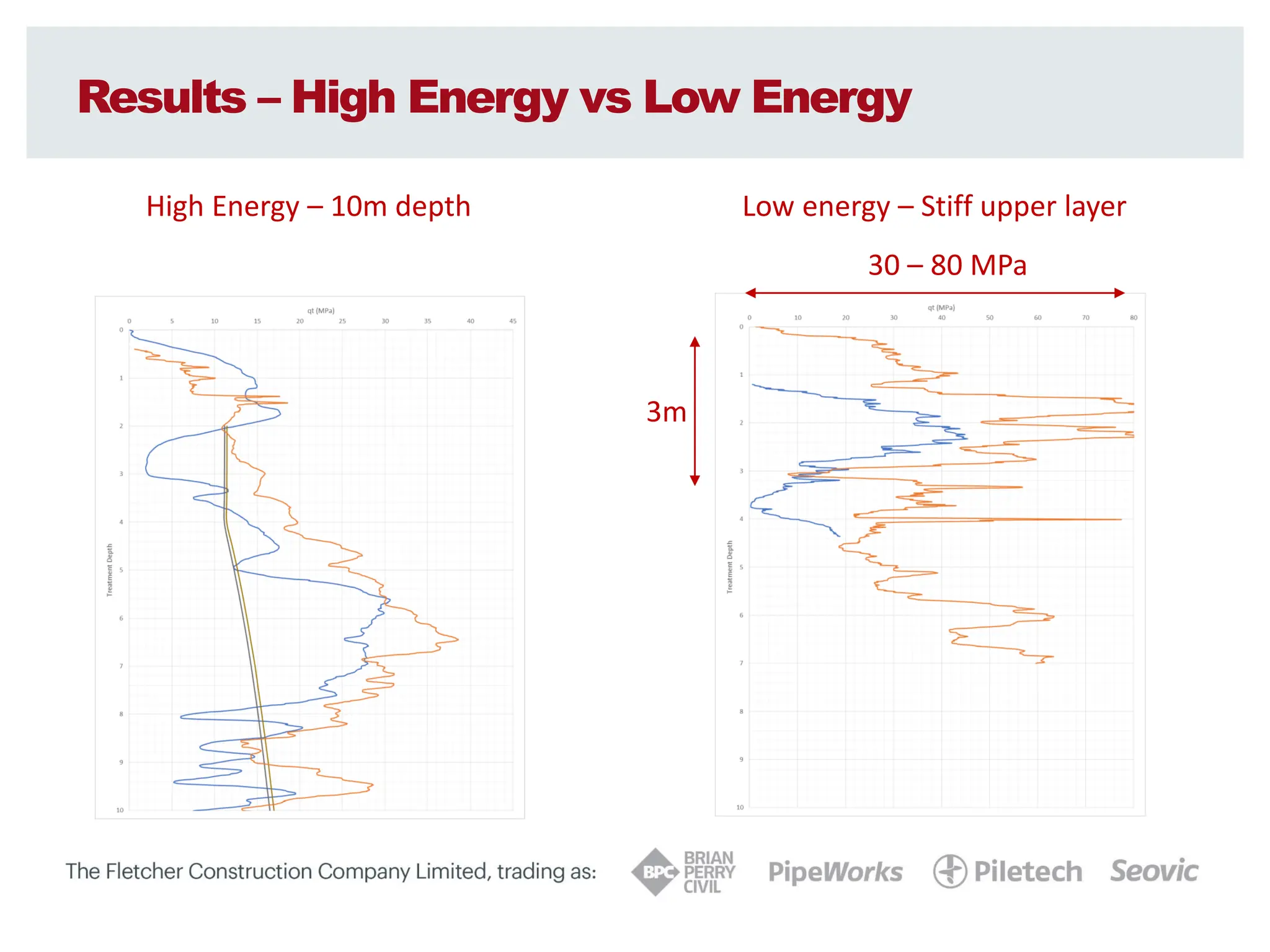

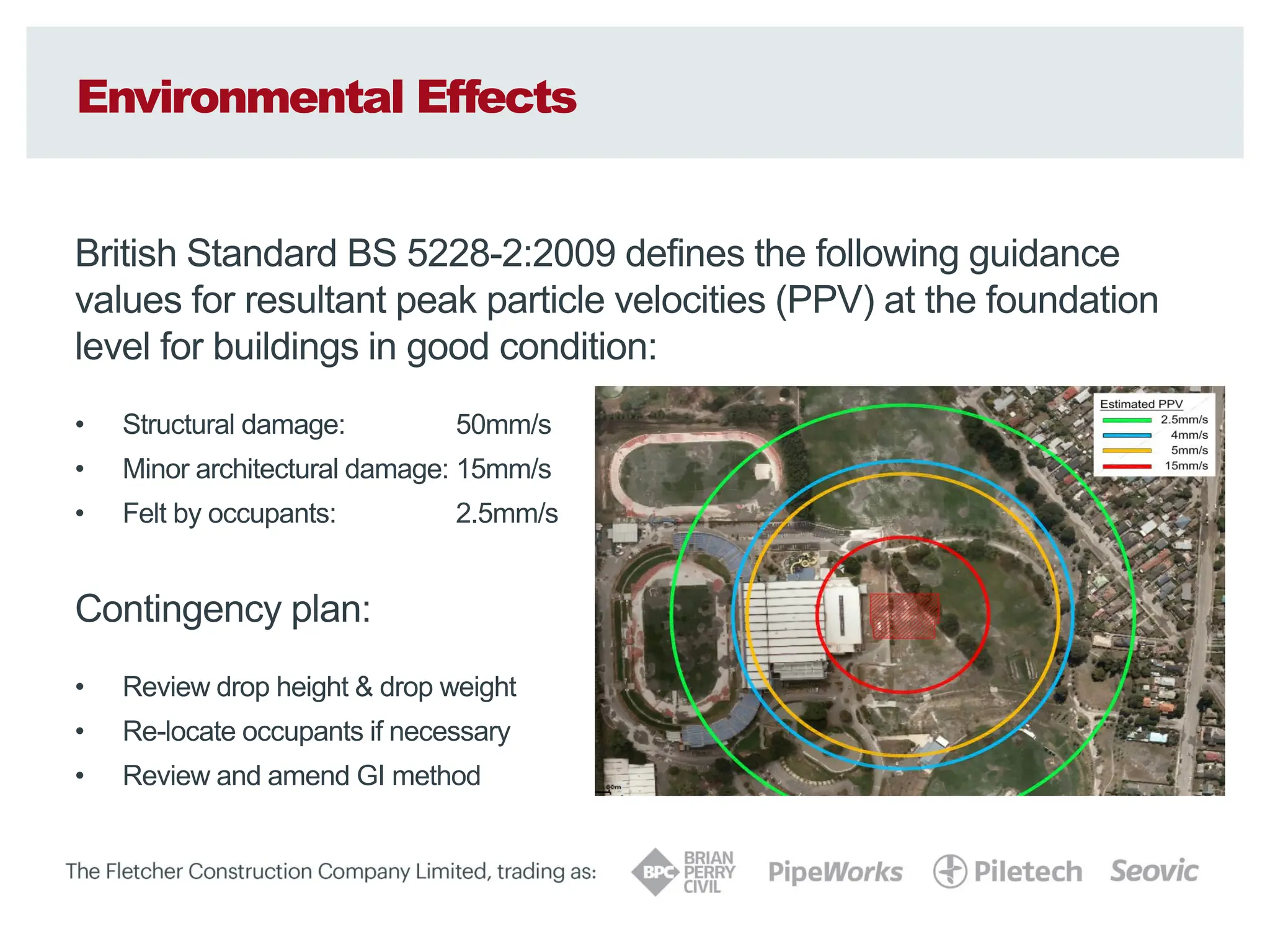

The document provides information on different ground improvement techniques, with a focus on dynamic compaction. It discusses dynamic compaction in detail, including its working principles in granular and cohesive soils, suitable soil types, design requirements, depth of treatment, and quality control. It also provides an example project (M2PP Expressway) where dynamic compaction was used to improve liquefiable soils and control seismic displacements, with mixed results depending on soil type. Stone columns were initially planned but dynamic compaction was ultimately used instead.