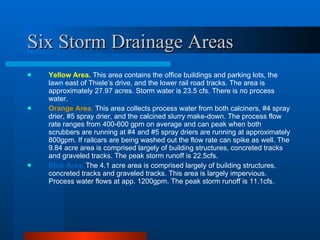

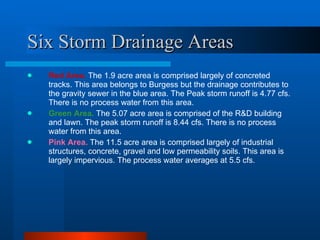

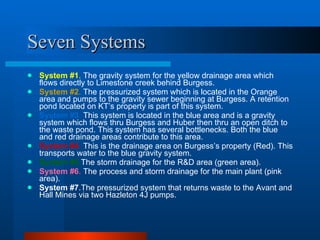

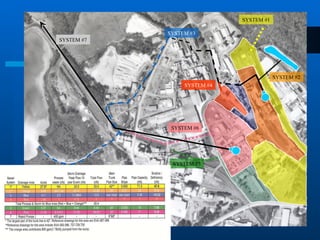

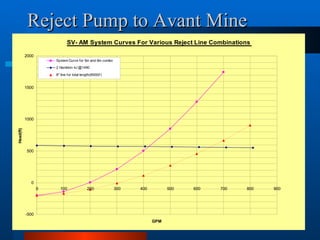

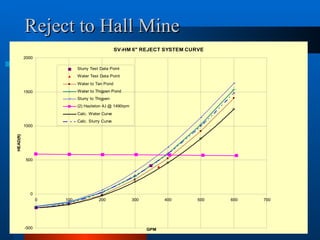

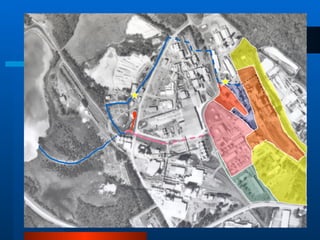

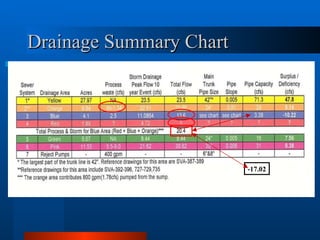

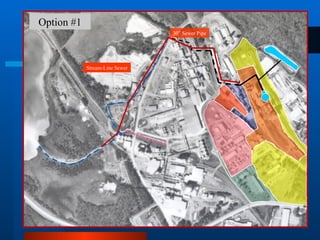

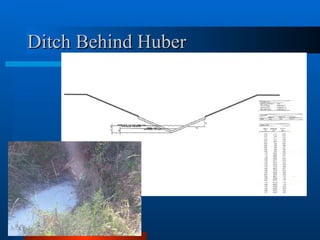

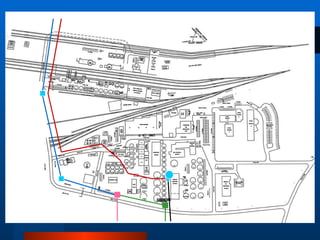

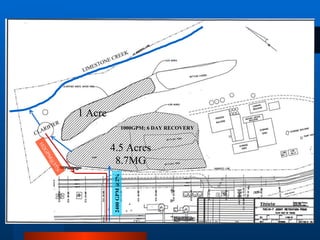

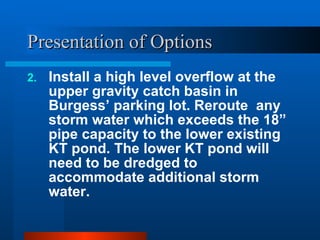

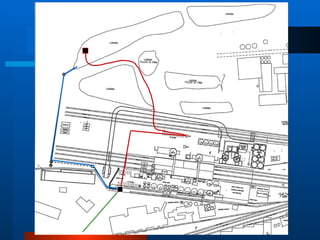

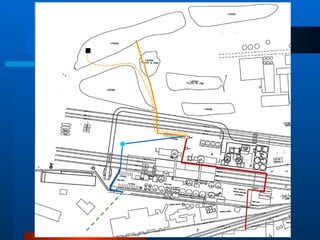

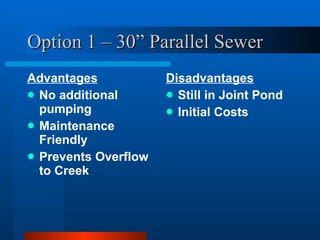

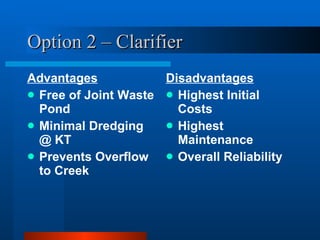

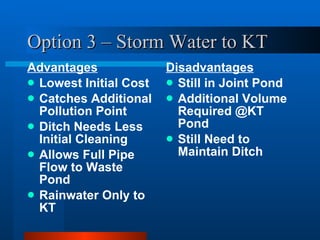

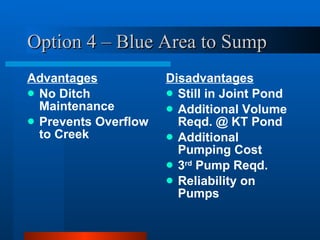

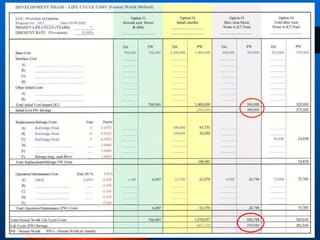

The document presents an overview of drainage issues and potential solutions for the Sandersville plant. It describes six existing storm drainage basins and their processes water flows. The key problem areas are catch basins and sewer pipes that cause bottlenecks. Four potential solutions are outlined: installing a parallel gravity sewer, sending all water to a larger clarifier pond, installing an overflow at an upper catch basin to route excess water to an existing lower pond, or pumping the "blue" area water across the plant to the main sewer line. Pros and cons of each option are discussed, along with estimated costs.