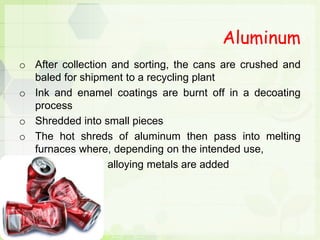

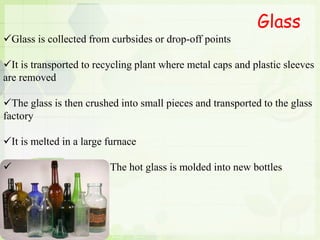

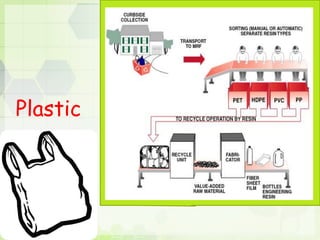

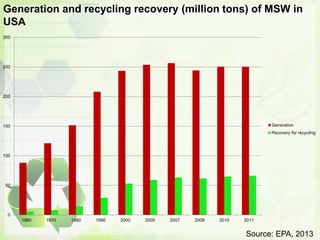

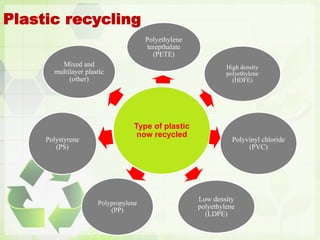

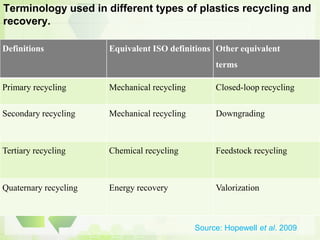

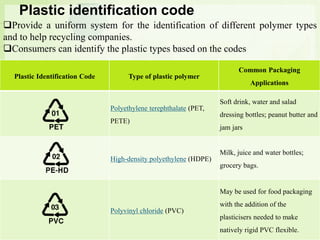

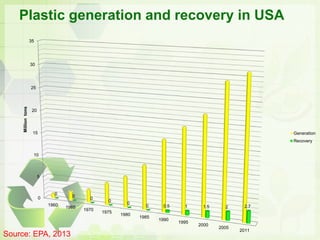

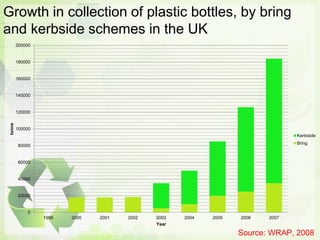

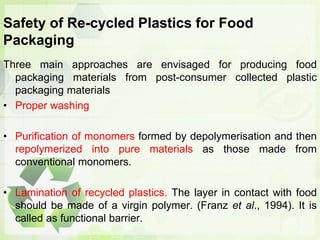

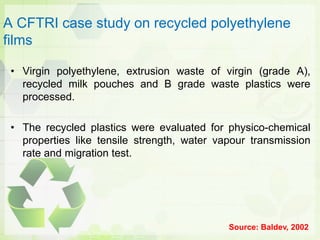

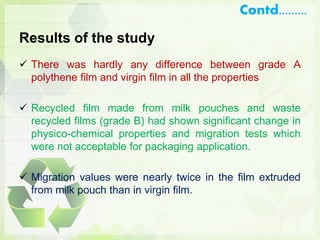

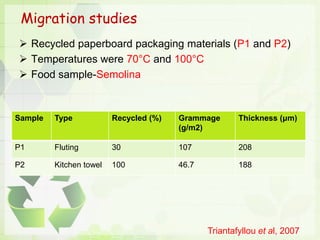

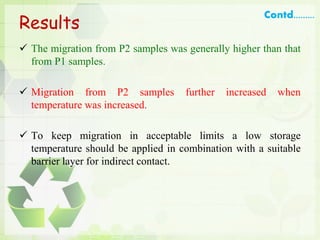

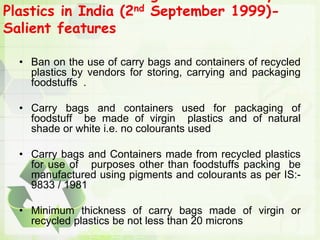

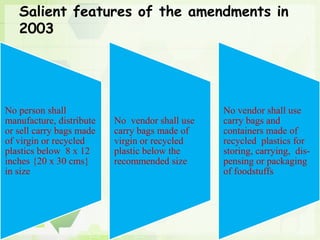

The document discusses recycling of packaging materials. It provides information on different packaging materials like paper, plastic, glass, metals and their decomposition times. It also discusses the various techniques used for recycling these materials including reuse, physical/mechanical, and chemical recycling. Safety issues for using recycled materials for food packaging are also summarized. The document emphasizes the benefits of recycling in terms of resource and energy conservation.