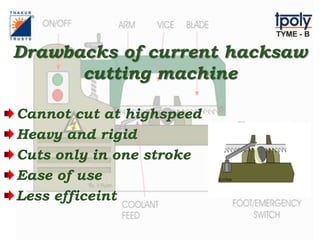

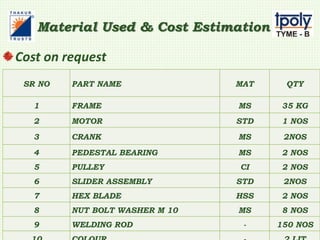

The document describes a new double hacksaw cutting machine that aims to improve upon previous hacksaw machines. It can cut materials at a higher speed and in a more efficient manner than traditional single-cut hacksaw machines. The double hacksaw machine uses a crank mechanism to convert the rotational motion of an electric motor into a reciprocating motion that drives two cutting blades simultaneously on either side of the machine. This double-cutting attachment allows the production rate to be increased compared to single-cut machines. The new machine is also more compact, portable, easy to use, and maintenance-friendly. It has potential applications for small-scale industries.