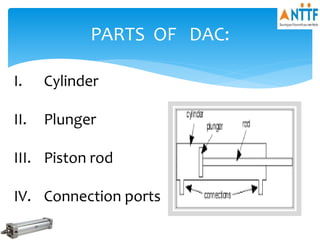

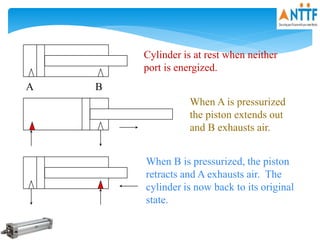

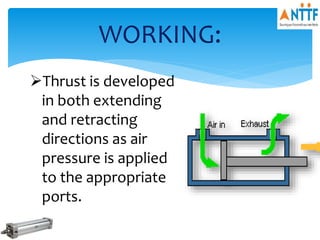

Double acting cylinders use pressurized air to extend and retract the piston through two connection ports. They have four main parts: the cylinder, plunger, piston rod, and connection ports. When port A is pressurized, the piston extends out and port B exhausts air, and when port B is pressurized the piston retracts and port A exhausts air. Double acting cylinders generate thrust in both directions from air pressure and are more compact and generate constant force compared to single acting cylinders.