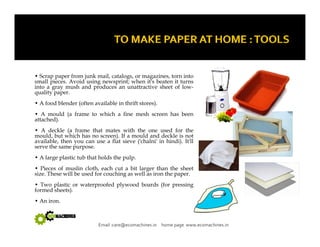

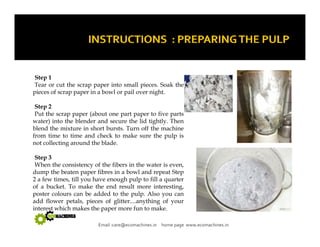

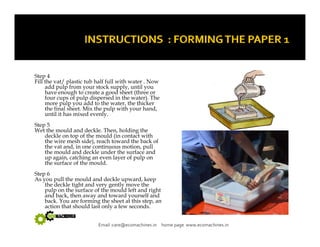

The hand-made paper industry significantly contributes to paper recovery, utilizing various household papers for recycling. A new paper recycling plant allows individuals, including children, to create their own stationery and paper products at home, promoting environmental awareness in schools. The document outlines a detailed step-by-step process for making recycled paper, emphasizing the simplicity and accessibility of the method.