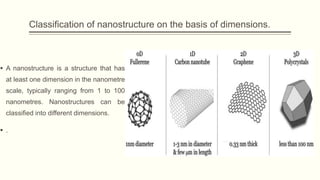

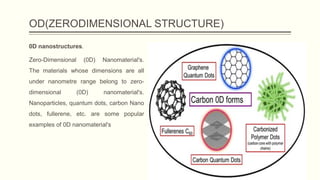

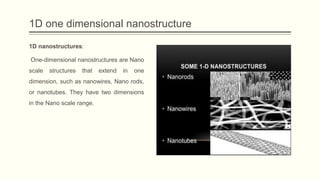

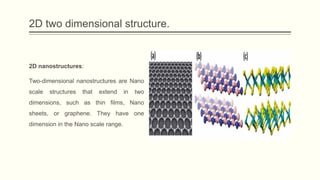

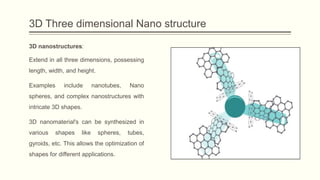

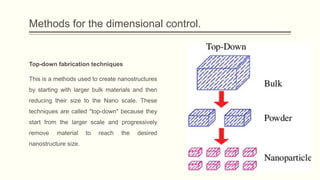

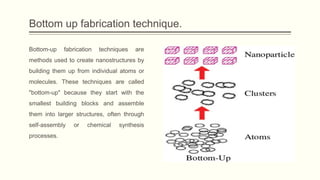

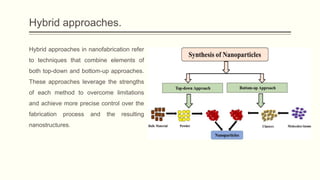

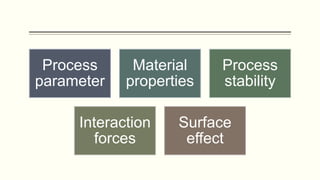

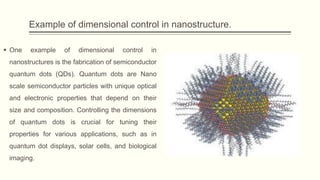

The document discusses dimensional control in nanostructures, emphasizing its importance in maintaining specific attributes like size, shape, and orientation which critically influence the materials' physical and chemical properties at the nanoscale. It outlines various classification methods and fabrication techniques (top-down, bottom-up, and hybrid), as well as factors affecting dimensional control, and highlights examples such as quantum dots. The document concludes with insights on challenges in the field and future perspectives for advancements in nanotechnology applications across diverse sectors.