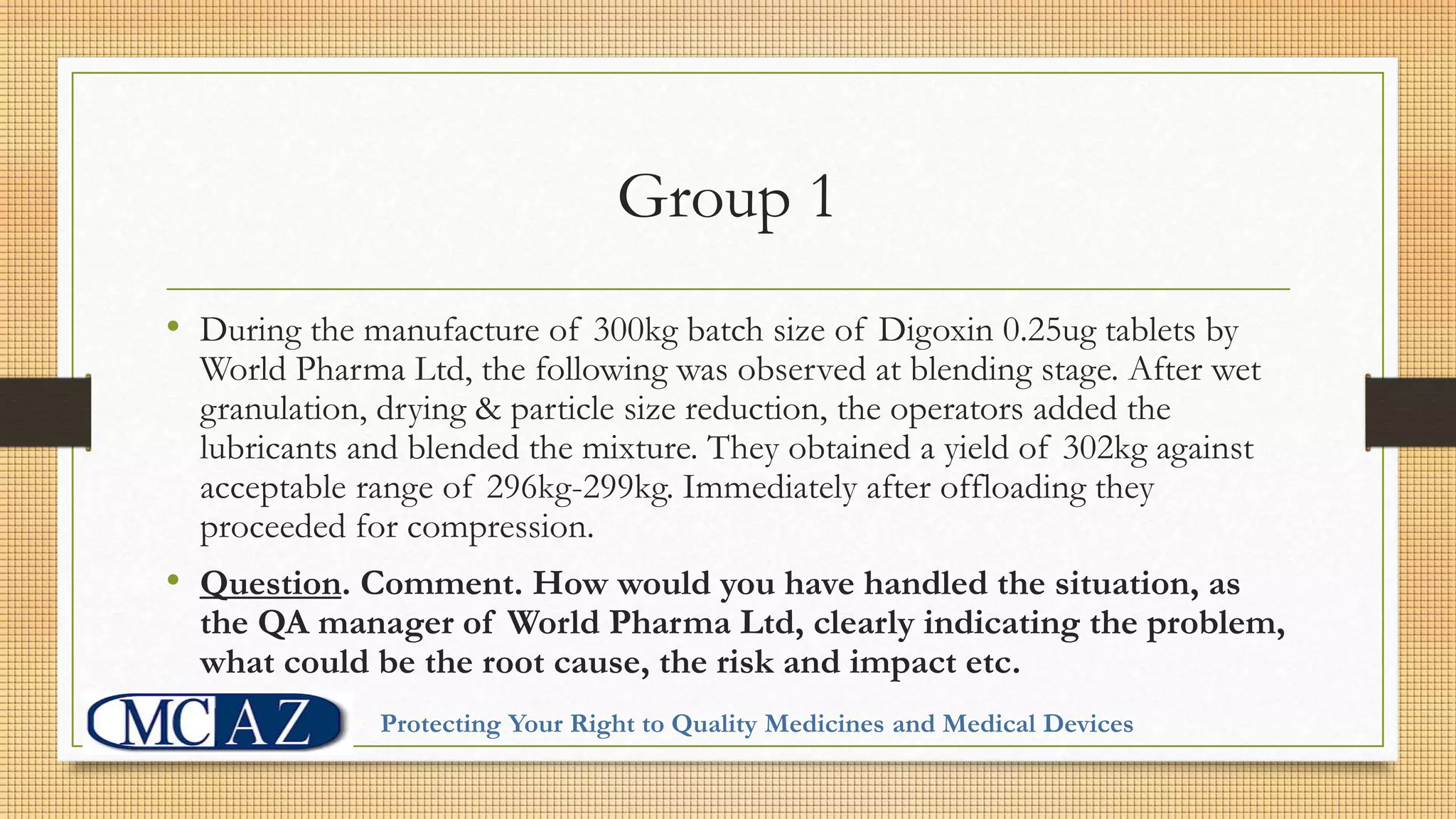

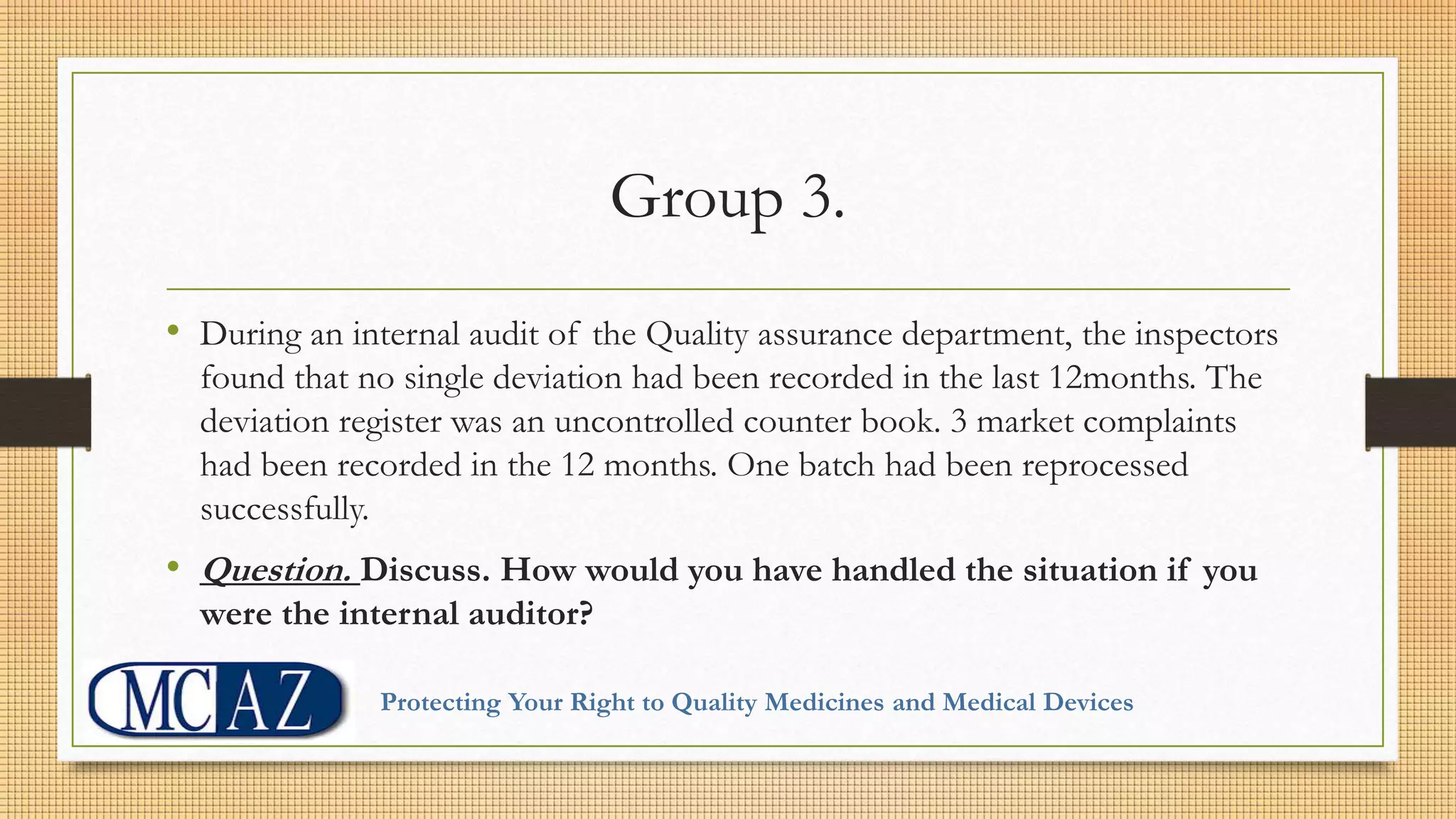

This document discusses deviation management in the pharmaceutical industry. It defines deviations as departures from approved procedures that can be planned or unplanned. Proper deviation management is important for product quality assurance, continuous improvement, regulatory compliance, and reducing rejections and complaints. Deviations should be reported in writing, investigated, classified based on risk and impact, approved or rejected, trended over time, and addressed to prevent future occurrences. Common inspection findings include a lack of proper deviation handling, documentation, investigation, trending and corrective actions.