This document summarizes the design and experimentation of a mobile mini ice-tube making machine. Key points:

- The machine was designed to produce 50 ice tubes using 2.5135 kg of water in 5 hours and 51 minutes. It uses a food flask as the cooling compartment within an insulated metal frame.

- Design calculations were performed to determine the required volume of water, heat removal needs, insulation requirements, and compressor capacity.

- The machine was fabricated using locally available materials like metal sheets and angle iron. Refrigeration components were installed and the system was tested.

- Experimental results showed the temperature reduction over time and the average dissolve times for ice tubes in different tray positions. The

![International Journal of Excellence Innovation and Development

||Volume 2, Issue 1, Jan. 2019||Page No. 056-061||

www.ijeid.com {IJEID © 2019} All Rights Reserved Page | 60

Results discussion

From Table 1 comparing the average dissolve time for

both trays, it is seen from the above calculation that the

top tray has the highest dissolve time of 33 minutes and

the bottom tray of 32 minutes, the difference in time of

dissolve is due to the time of unloading each tray from

the system since the time difference is some seconds

interval.

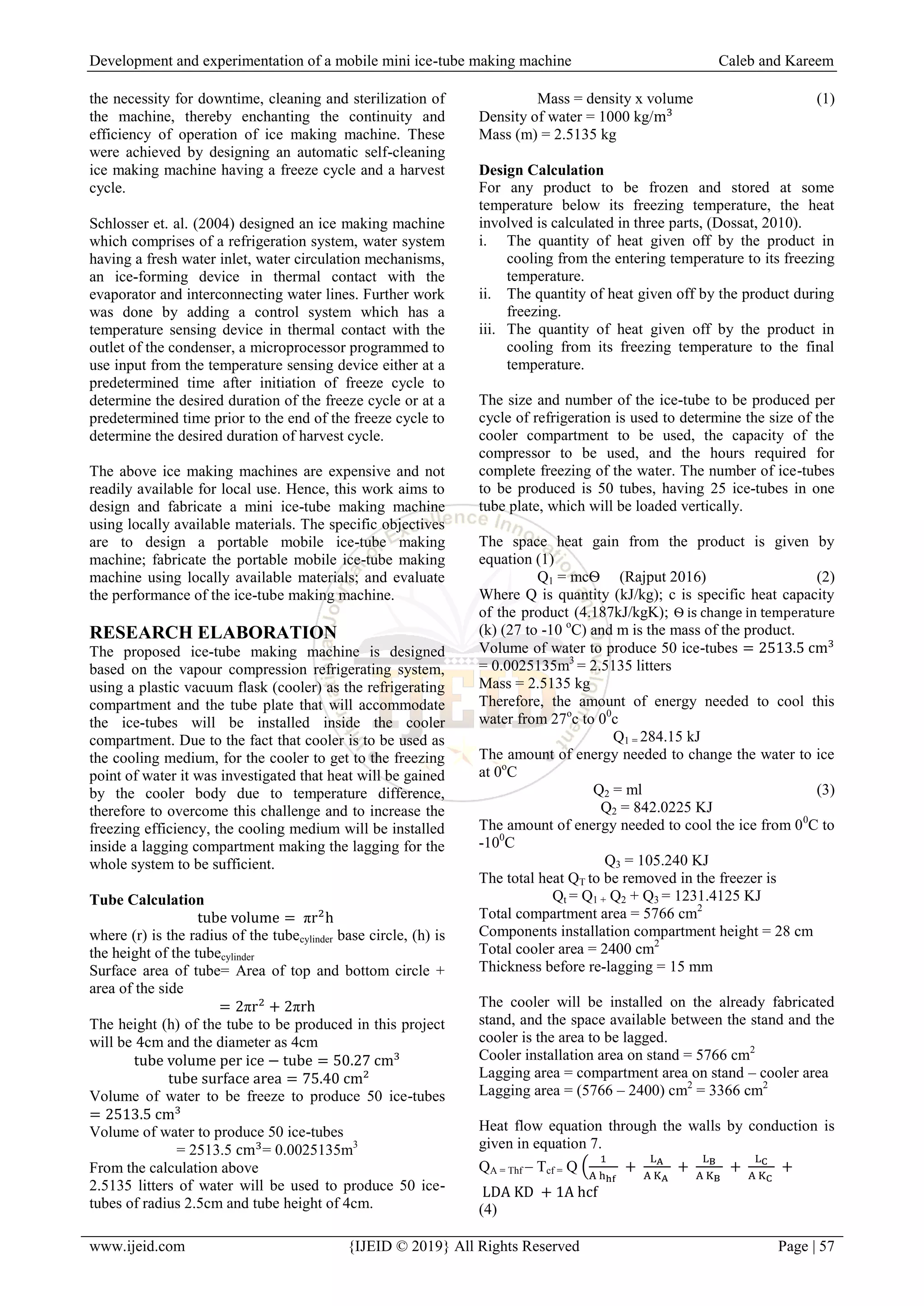

From Figure 2 at 90 minutes of continuous system

running, the water reached temperature of 0 0

C and after

90 minutes the temperature of the system reduced by 1

0

C interval for each minutes, this is as a reason that the

system is doing much work to transform the water to ice

at those temperatures. The temperature remains constant

at -3 0

C from 180 to 210 minutes; this might be as a

result that the ice formed is trying to harden changing

from ice slurries to ice-tube.

After 360 minutes of continuous operation of the system

it was noticed that the inside temperature of the system

did not change from -10 0

C, from this observation, it can

be said that the system has reach its constant enthalpy,

therefore the system can continue to run for various

hours with constant temperature of -10 0

C.

Coefficient of performance (C.O.P)

The coefficient of performance is the ratio of the cooling

load to the compressor power; the COP is mainly

affected by the change in evaporating and condensing

temperature.

Compressor power = 0.1647 hp

Ambient temperature = 27 0

C, Temperature after 30

minutes = 11 0

C

Heat removed per 30 minute (q) =

–

Heat removed per 30 minute (q) = 0.01867 kW

Actual C.O.P = (Rajput 2016) (9)

From (equation 18) Actual C.O.P =

COP theoretical =

COP theoretical = 7.108

Refrigerating efficiency =

Time taken to freeze 1kg of water = 2.15 hours

Time taken to produce ice-tube of 2.5135kg of water (50

ice-tubes) = 5.51 hours

Plate 4: Ice-Tube Produced

CONCLUSION

A portable/mobile ice-tube making machine was

developed and evaluated. The machine ran for 5 hours

51 minutes to produce 50 pieces of ice-tube with 2.5135

kg of water using two ice-tube tray 25 pieces per tray,

and all part used for fabrication were selected to reduce

weight of the machine, reduce cost of production and

also increase the efficiency of the machine.

REFERENCES

[1] Abubakar, M., Andrew E. E., Akinola A. A.,

Abdulkadir B. H. (2012). Development and

Evaluation of a Prototype Refrigerated Cooling

Table for Conference Services. International

Journal of Engineering and Technology (IJET). 4

(2), 97 – 108.

[2] Ajeet, K. R. and Salem A. M. (2016). Study of

Performance Evaluation of Domestic Refrigerator

Working With Mixture of Propane, Butane and

Isobutene Refrigerant (Lpg). International Journal

of Mechanical Engineering and Technology

(IJMET). 7(3).

http://www.iaeme.com/IJMET/issues.asp?JType=I

JMET&VType=7&IType=

[3] Akinola, A. O.; Mogaji, T. S. and Adewole, K. A.

(2015). Development of a Solar-Powered Mobile

Refrigerator. International Journal of Emerging

Technology and Advanced Engineering

www.ijetae.com 5(9).

[4] ASHRAE, (2006). “Ice Manufacture,” ASHRAE

Handbook: Refrigeration. Inch-Pound Edition, pp.

34-41,

[5] Dickson, G and Westergaard, R.K (1984), Ice

Making Machine United States Patent 3791163

www.freepatentonline.com

[6] Dossat R.J, (2010) Principles of Refrigeration, 4th

edition Mohinder Singh Segwal for Wiley Eastern

Limited London, pp 206-213, 340-430

[7] Goldstein, V, (1991) Ice Making Machine

European Patent Application EP0316966.

www.freepatentonline.com

[8] Golob, P., Farrell, G. and Orchard, J. E. (2002).

Postharvest science and technology, principles and

practices. Blackwell Science. 554p.

[9] Kader, A. A. (2002a). Postharvest Technology of

Horticultural Crops. University of California,

Division of Agriculture and Natural Resources.

2nd Edition, Publication 3311, Berkeley, CA,

USA.

[10] Lemboye, K. T.; Layeni, A. T.; Oduntan, K.;

Akintunde, M. A. and Dahunsi, O. A. (2015).

Developing a Two Stage Cascade Compressor

Arrangement for Ice Block Production. Journal of

Machinery Manufacturing and Automation. 4 (2),

PP. 10-16.

[11] Meier, Gary B. (1992) Automatic ice block

machine, United States Patent

5167132.www.freepatentonline.com

[12] Rajput, R.K (2016) heat and mass transfer S.

Chand & Co. Ltd, New Delhi, pp150](https://image.slidesharecdn.com/ijeid201056061-190210091136/75/Development-and-Experimentation-of-a-Mobile-Mini-Ice-tube-Making-Machine-5-2048.jpg)

![Development and experimentation of a mobile mini ice-tube making machine Caleb and Kareem

www.ijeid.com {IJEID © 2019} All Rights Reserved Page | 61

[13] Sargent, S. A., Talbot, M. T. and Brecht, J. K.,

(1988). Evaluating Precooling Methods for

Vegetable Packinghouse Operations. Florida

Cooperative extension Service. Proc. Fla. State

Hort. Soc. Vol. 101, pp 175-182.

[14] Schlosser, C.E, Mueller, L.G and McDougal, G.

(1996). Ice making machine United States Patent

5586439. www.freepatentonline.com

[15] Schlosser, C.E, Pierskalla, C.J and Krcma, G.F

(2004) ice making machine and control method

therefor, European Patent EP0869321.

www.freepatentonline.com

Biography of Author(s)

CALEB, O. O. (B. Eng. Mechanical Engineering, M.

Eng. Building Services Engineering) is a lecturer at the

Department of Mechanical Engineering Federal

University of Technology Akure, Ondo State, Nigeria.

KAREEM, B. (B. Eng. Mechanical Engineering, M.

Eng. Production Engineering, PhD in Industrial

Engineering,) is Professor at the Department of

Industrial and Production Engineering Federal

University of Technology Akure, Ondo State, Nigeria.](https://image.slidesharecdn.com/ijeid201056061-190210091136/75/Development-and-Experimentation-of-a-Mobile-Mini-Ice-tube-Making-Machine-6-2048.jpg)