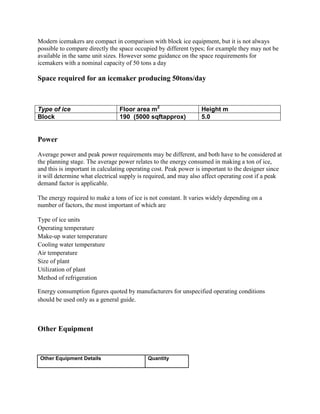

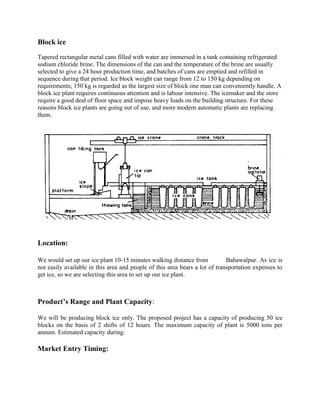

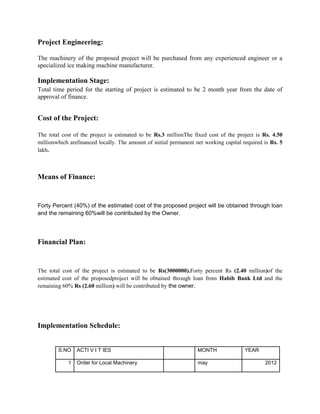

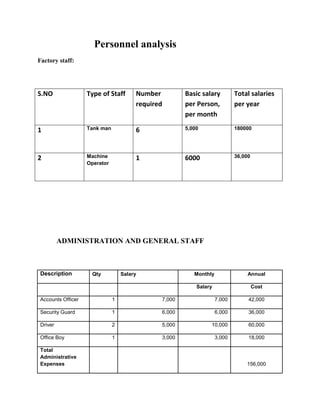

The document proposes setting up a new ice plant in Bahawalpur, Pakistan with a capacity of 50 tons per day. It discusses the history of ice making technology, machinery and equipment requirements including generators, transformers and water boreholes. The plant will produce ice blocks weighing 130-150kg each. It analyzes the local market demand, target customers, distribution channels and provides a financial plan and implementation schedule for the project.