Embed presentation

Download to read offline

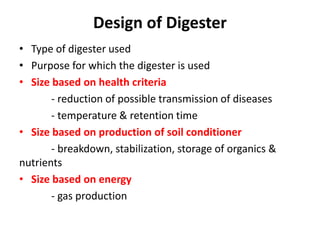

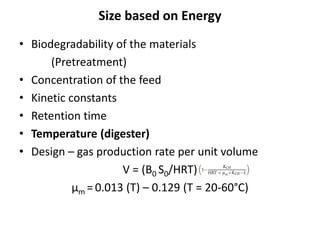

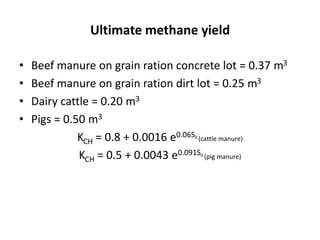

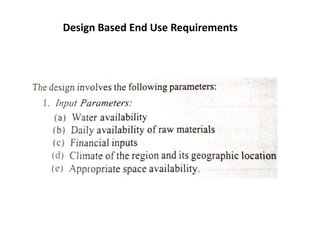

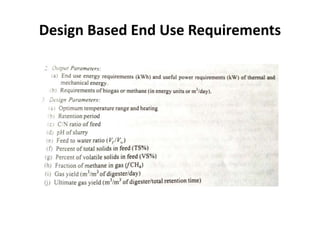

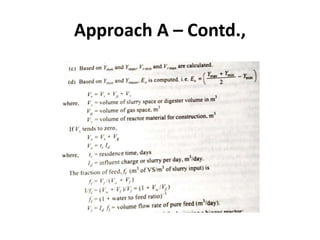

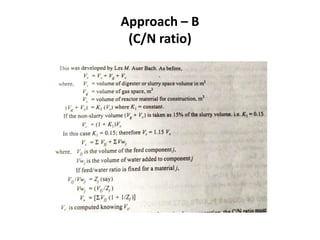

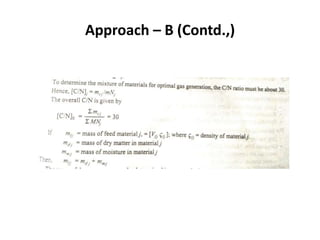

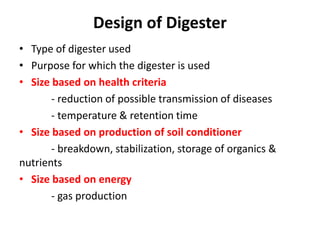

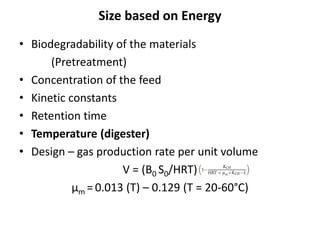

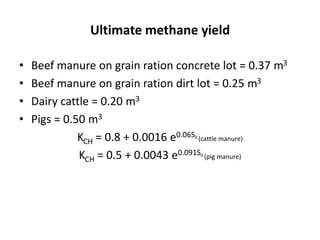

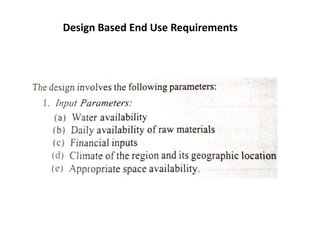

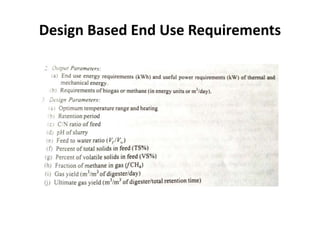

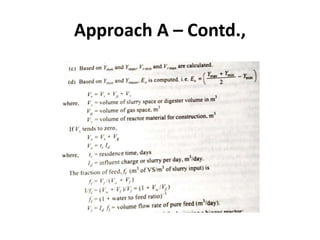

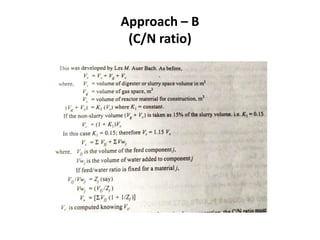

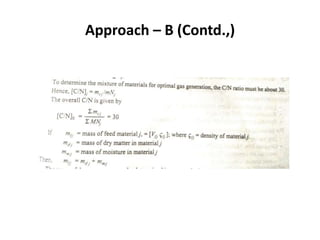

The document discusses the design of digesters, focusing on size calculations based on energy production and end user requirements. It outlines various factors such as biodegradability, concentration of feed, and health criteria that influence digester design, including gas production rates for different types of animal manure. Two design approaches are presented, emphasizing the importance of end-use requirements in determining the most effective digester specifications.