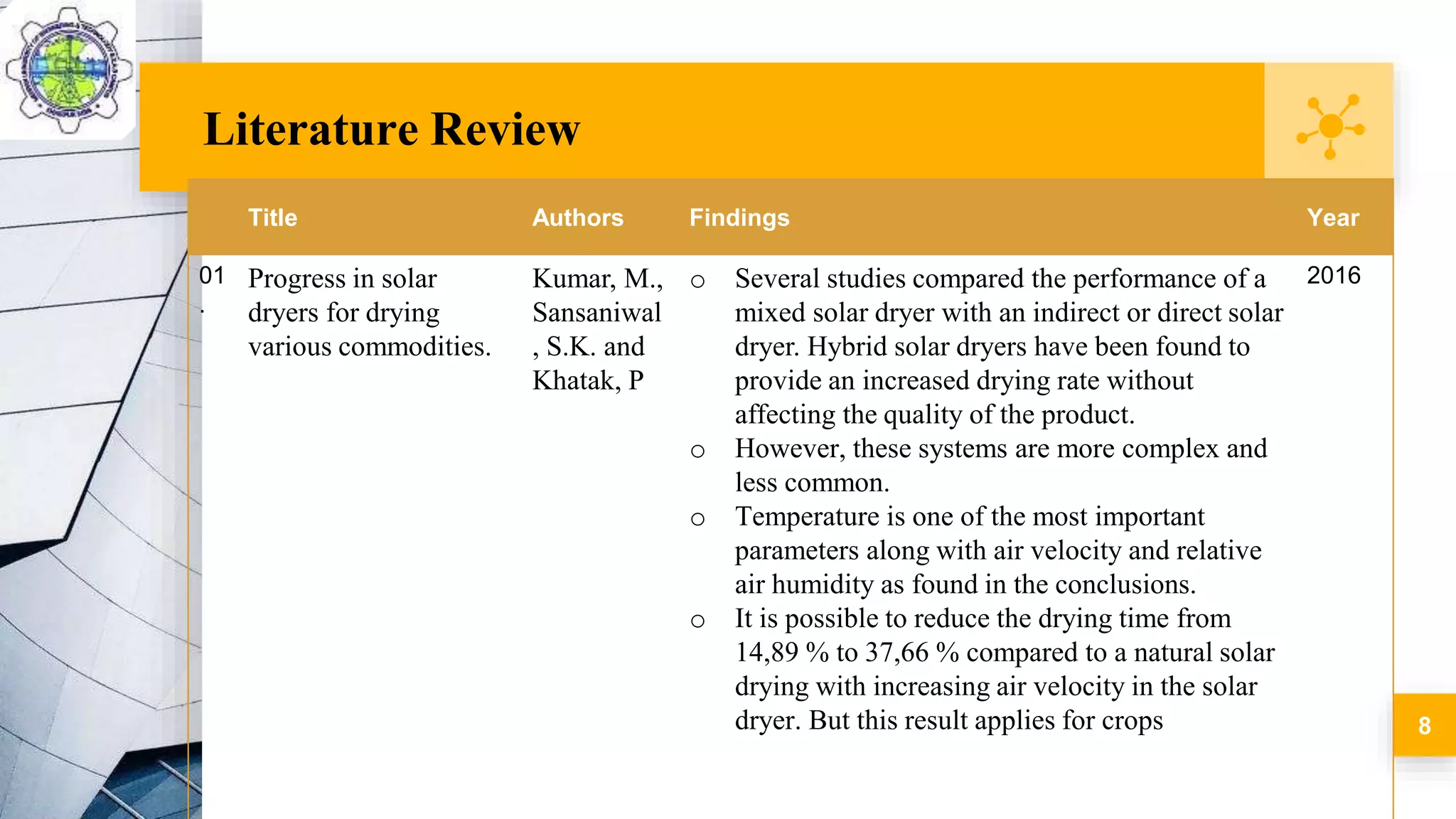

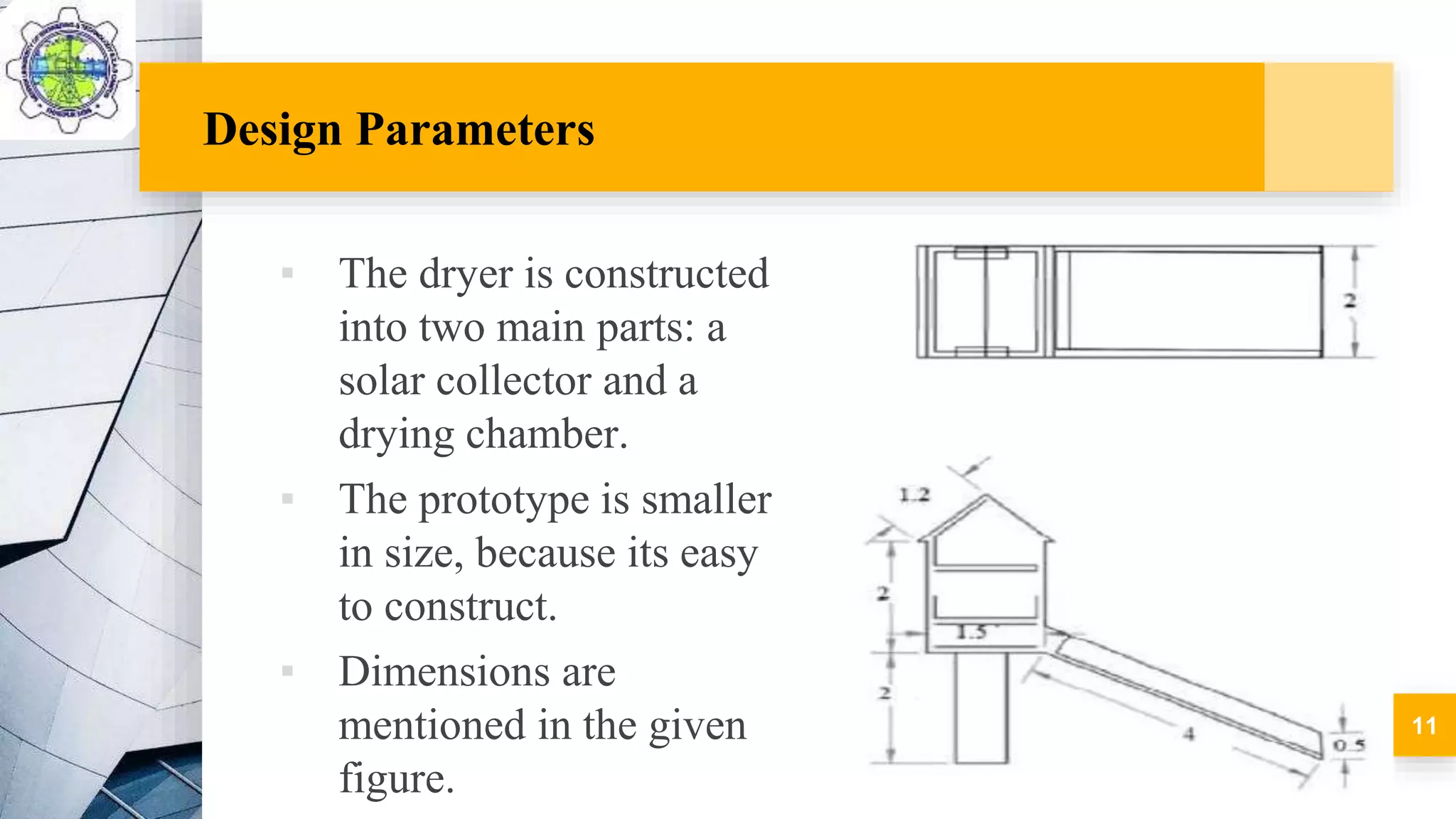

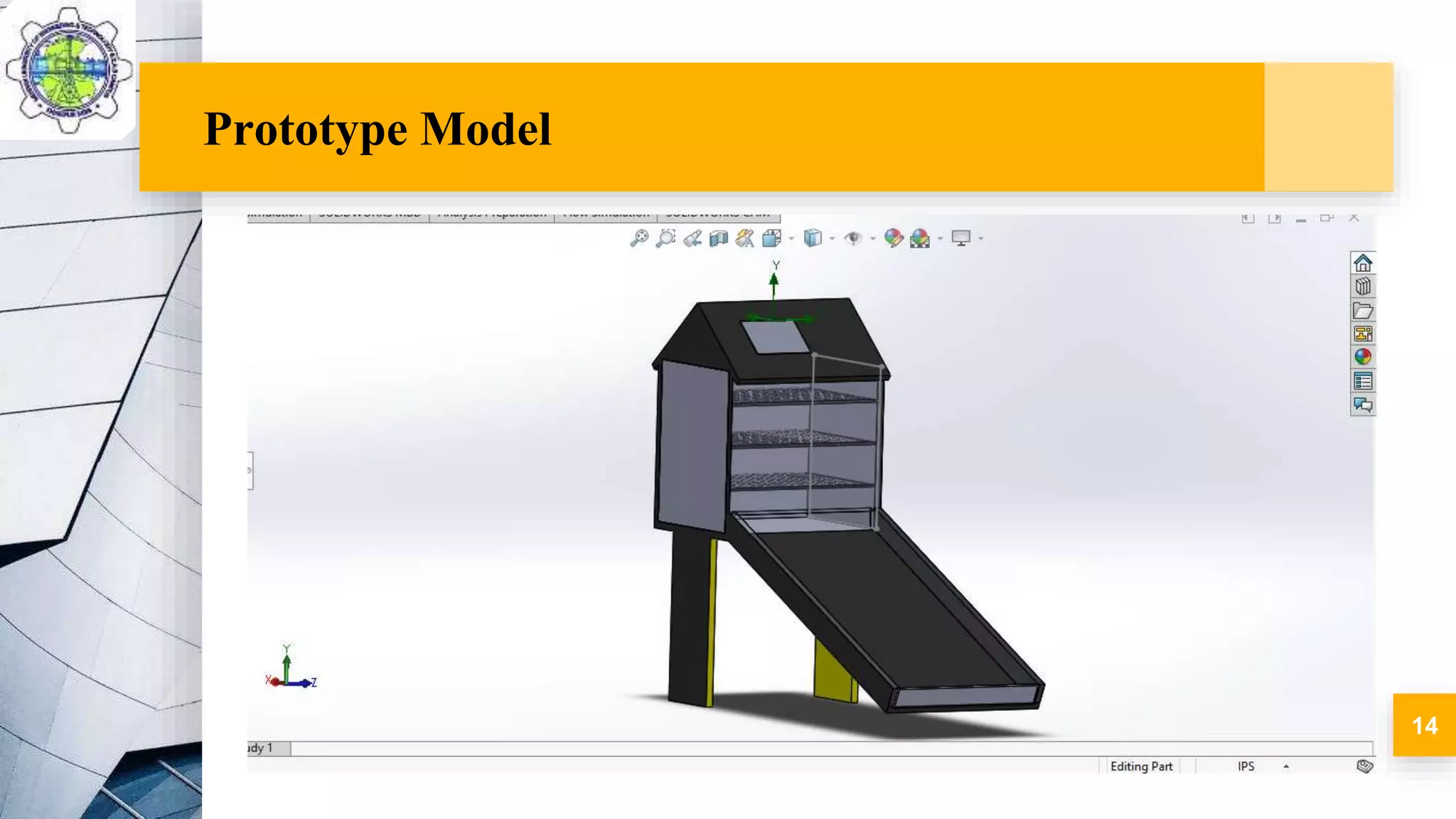

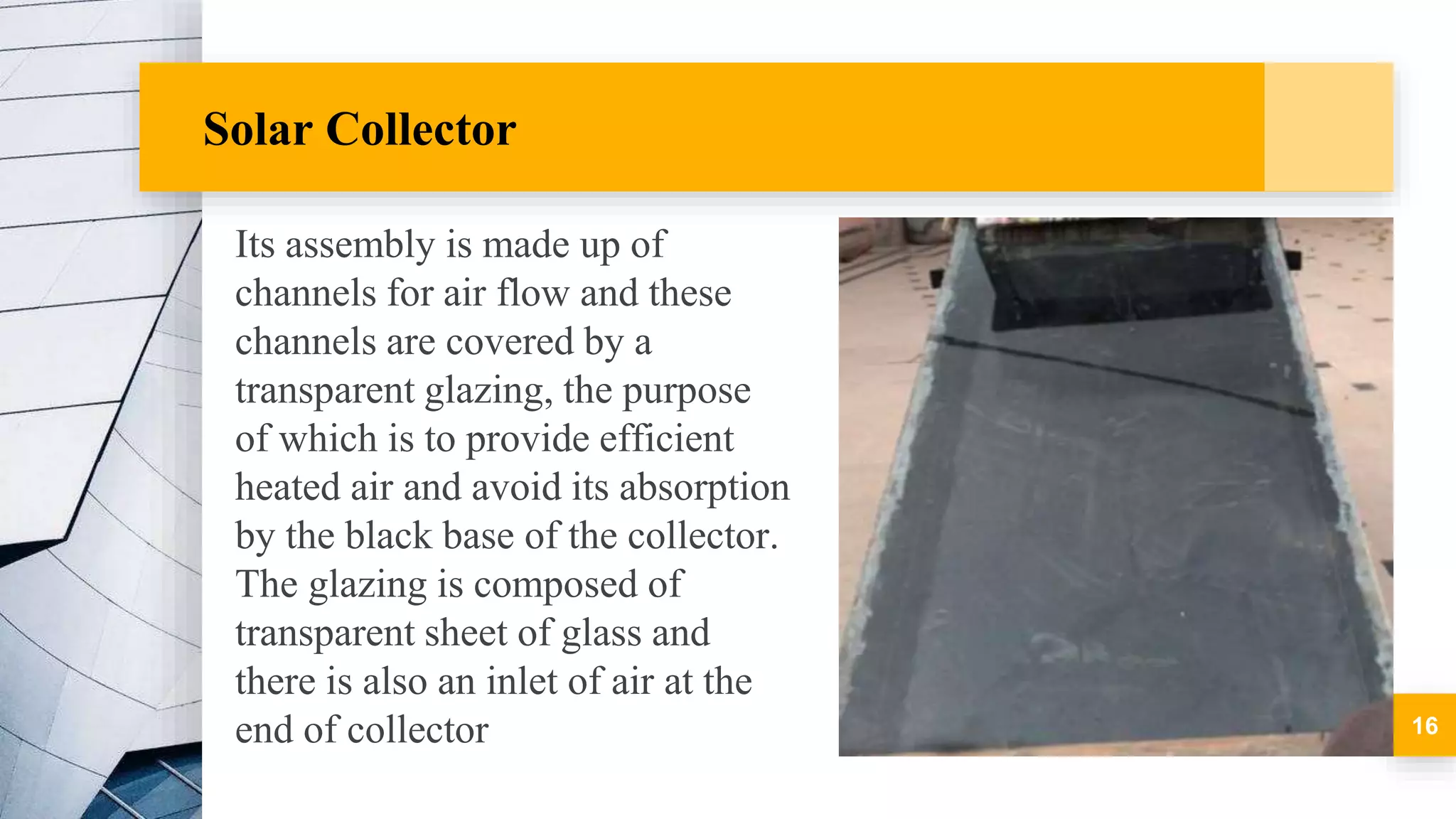

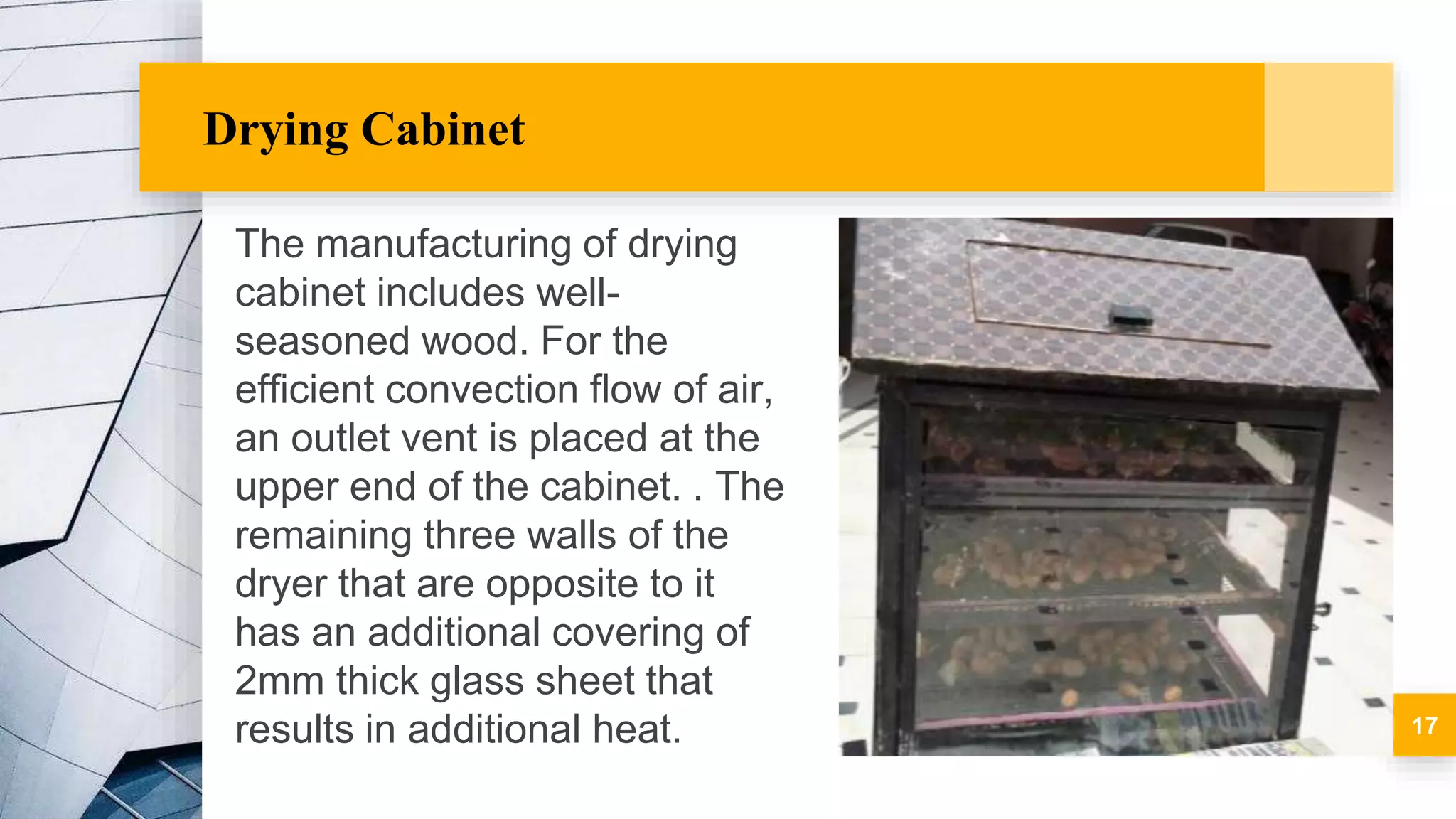

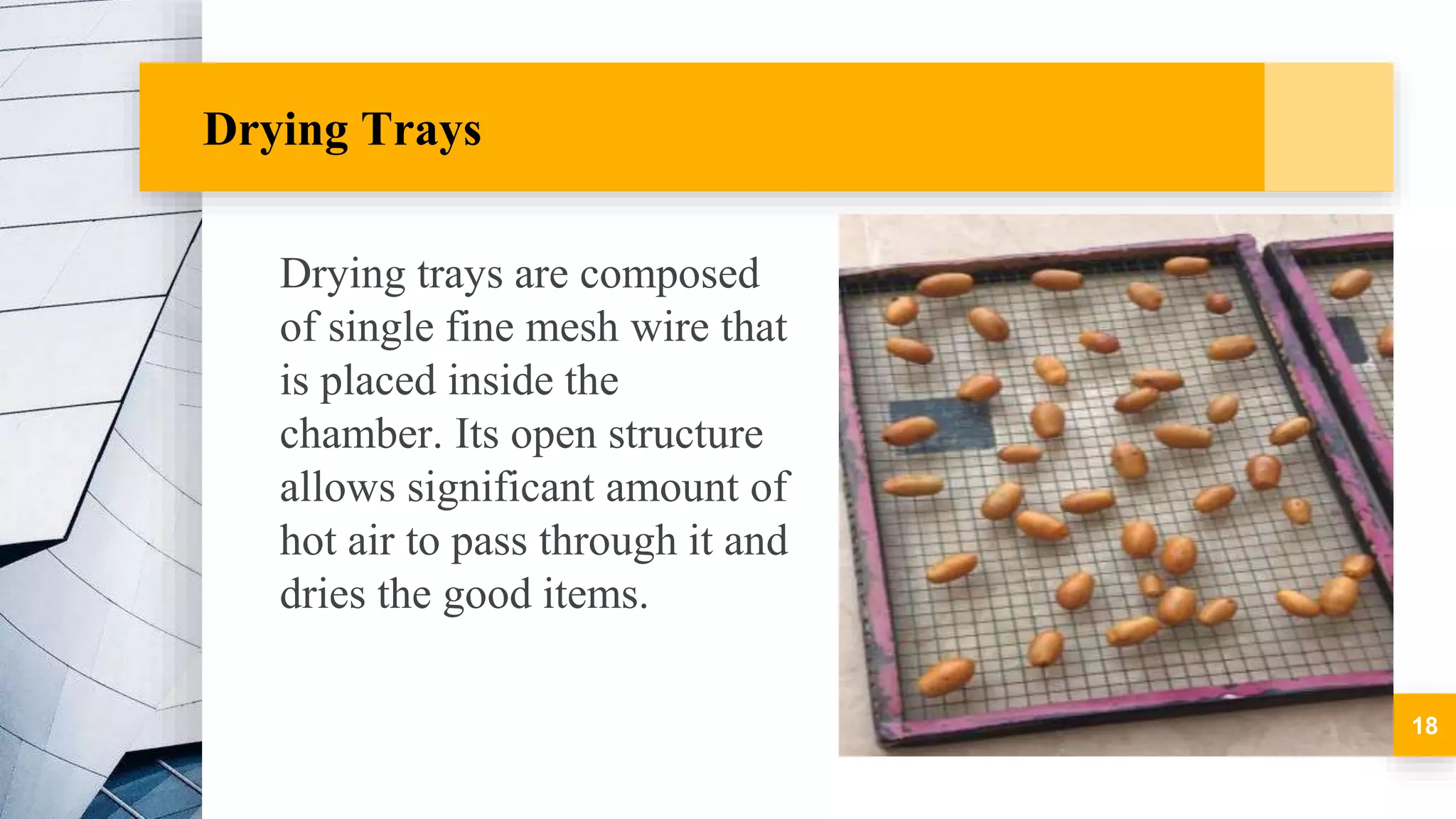

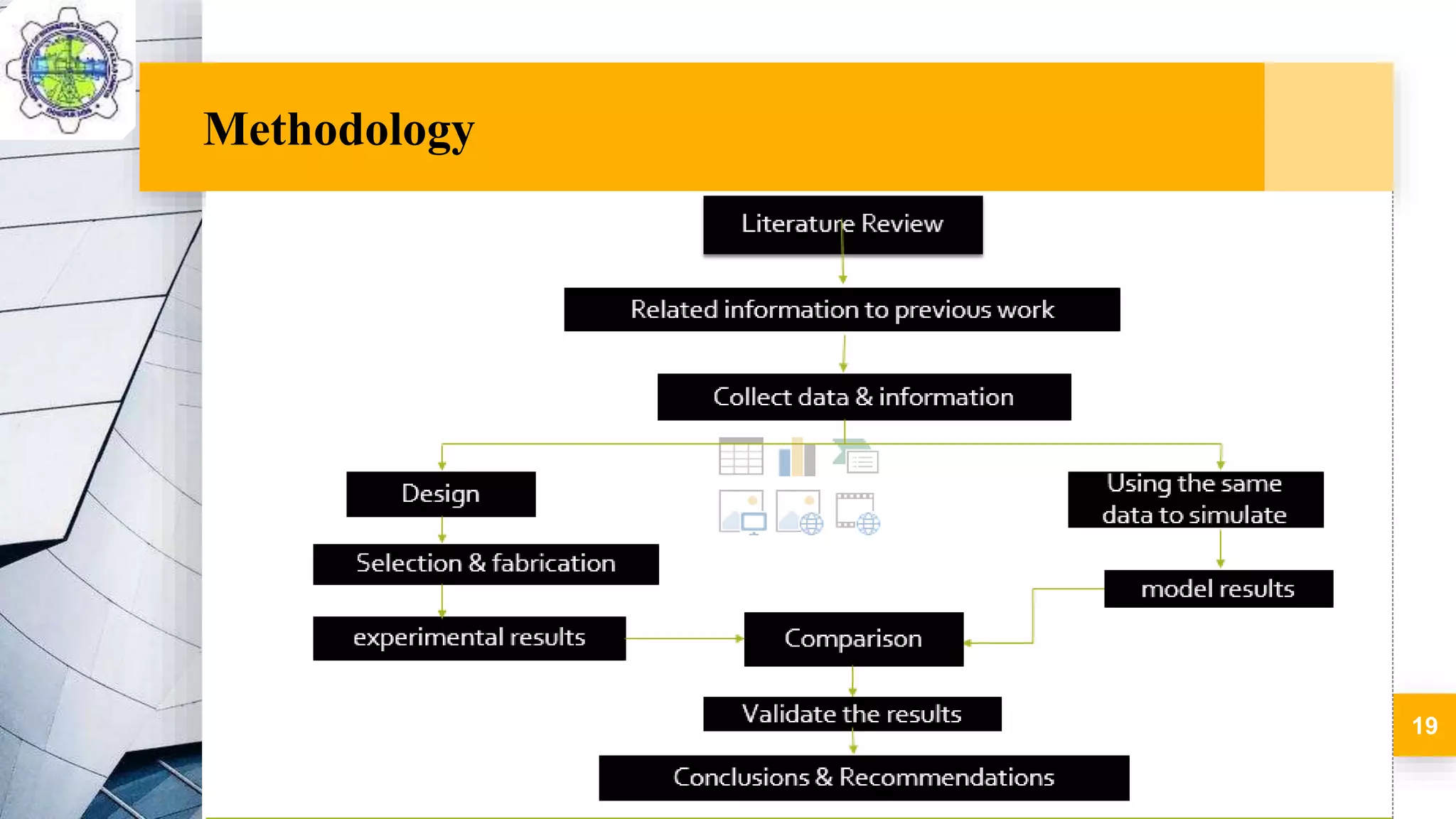

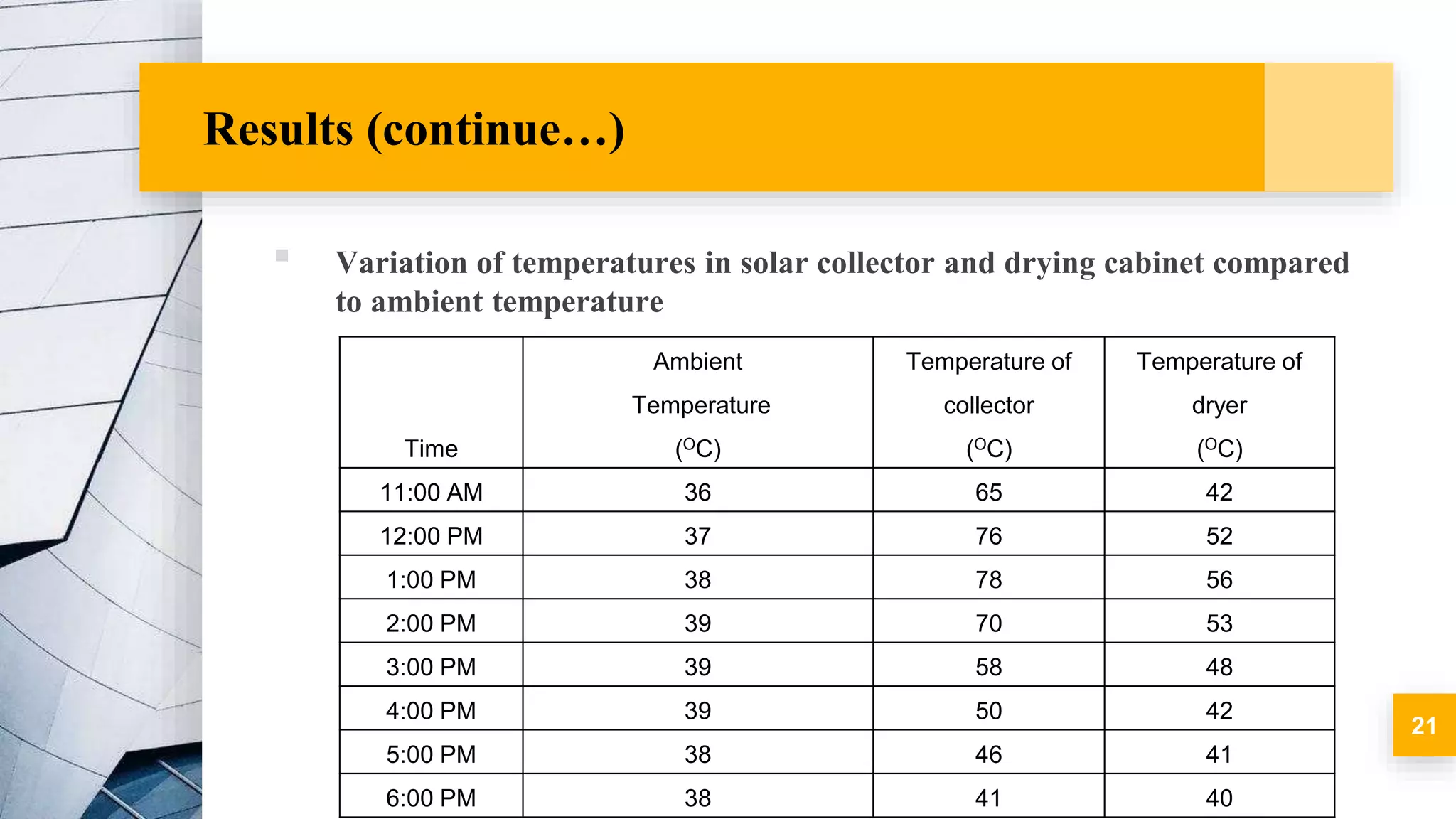

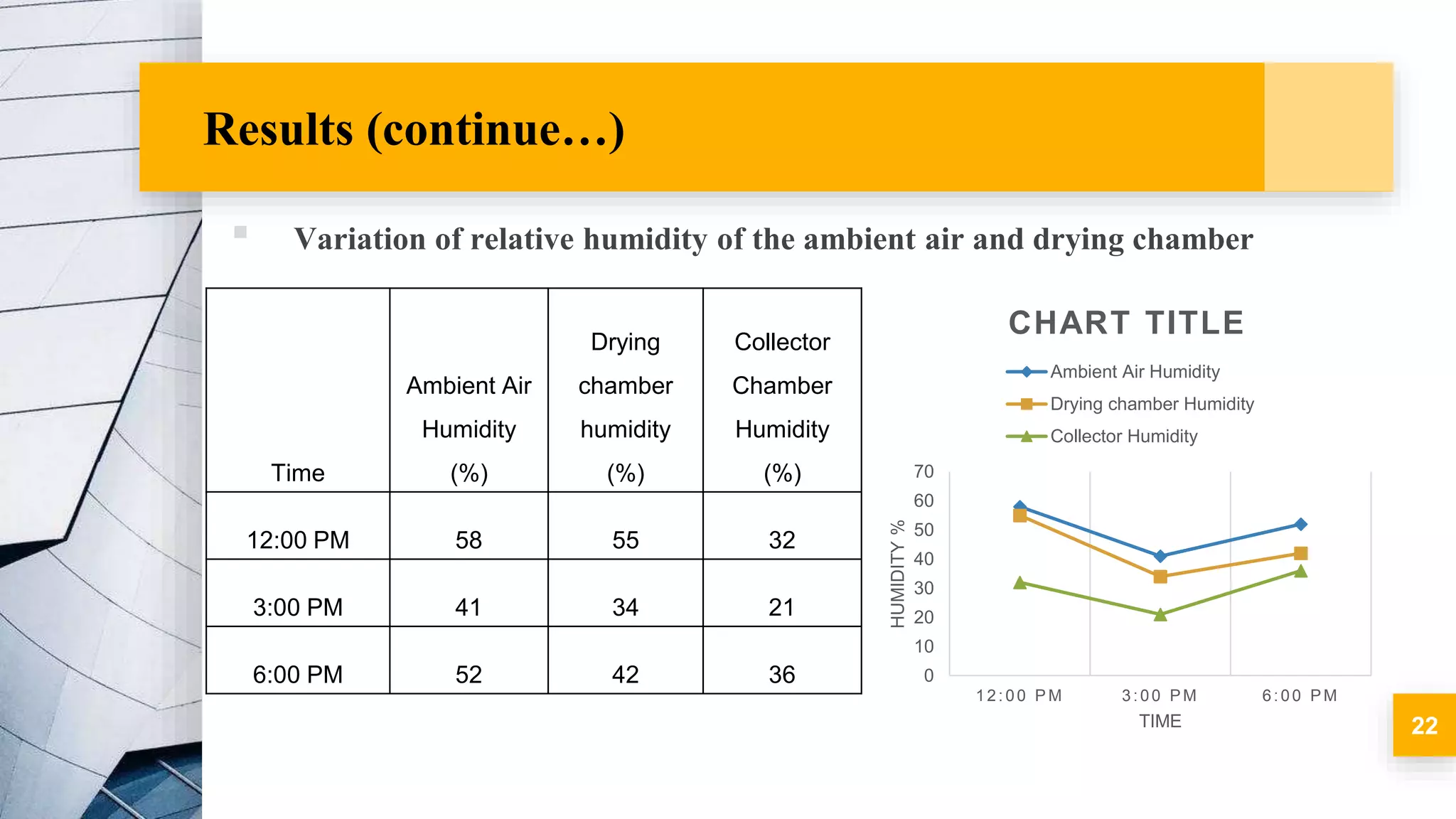

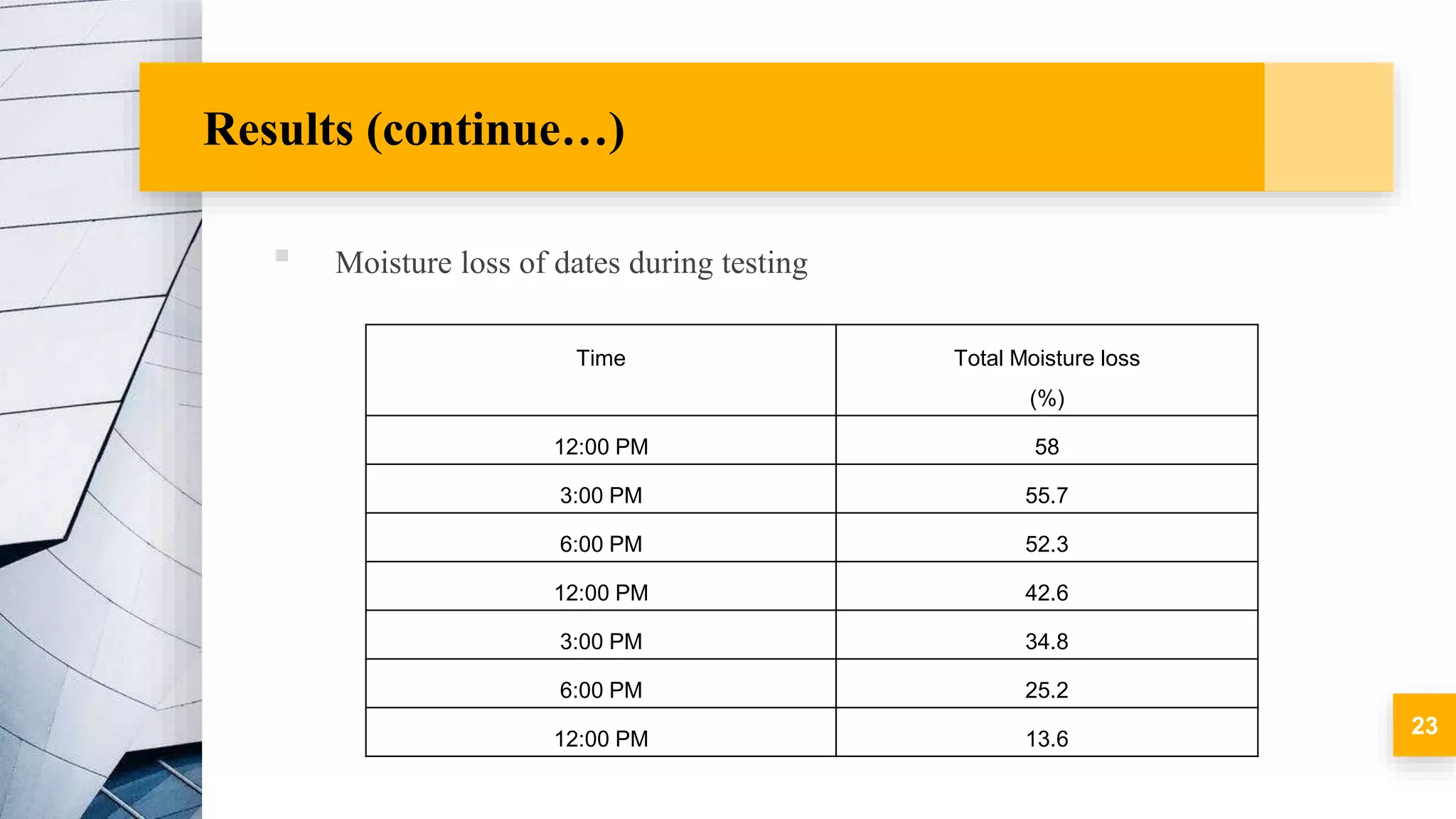

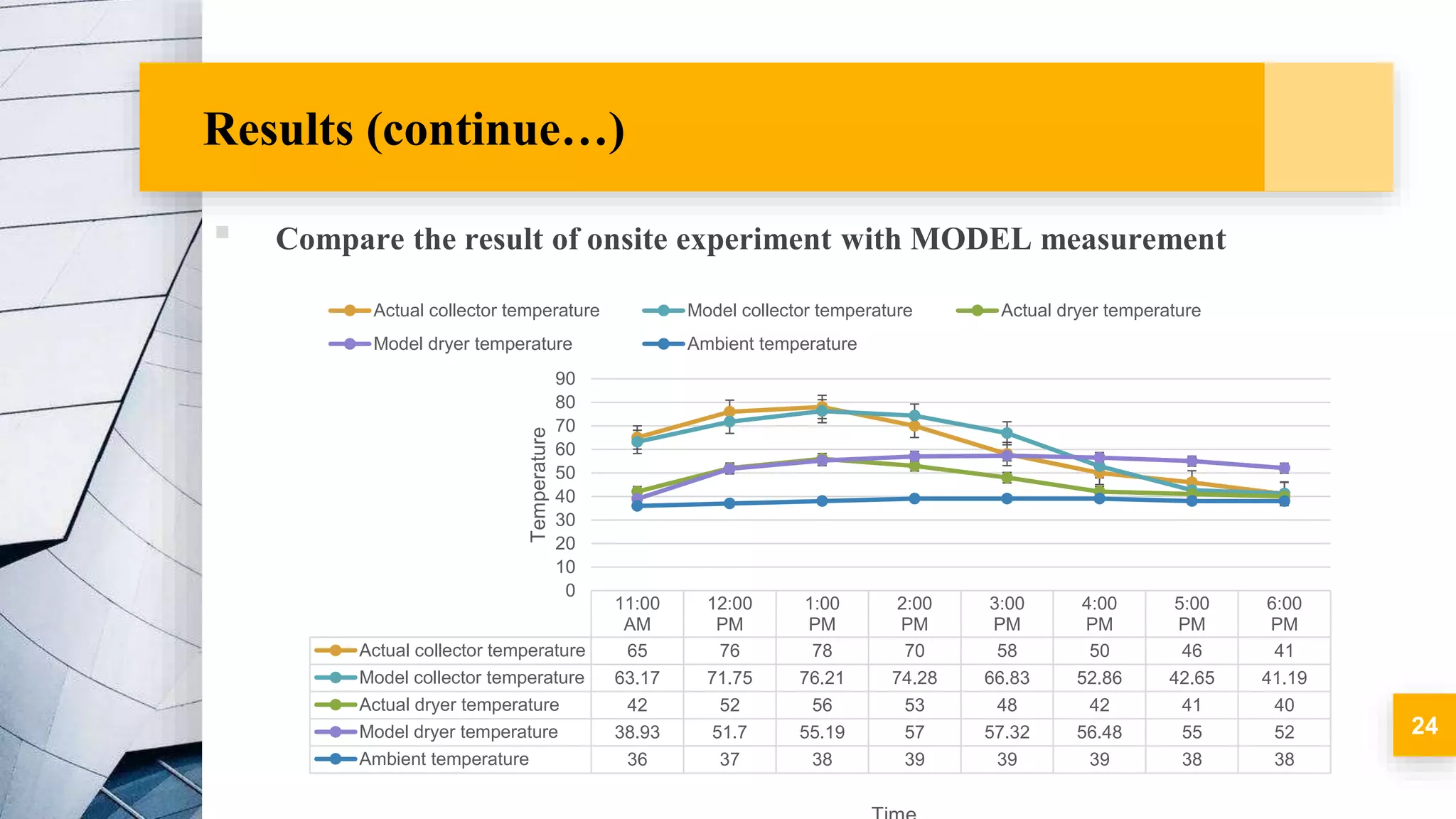

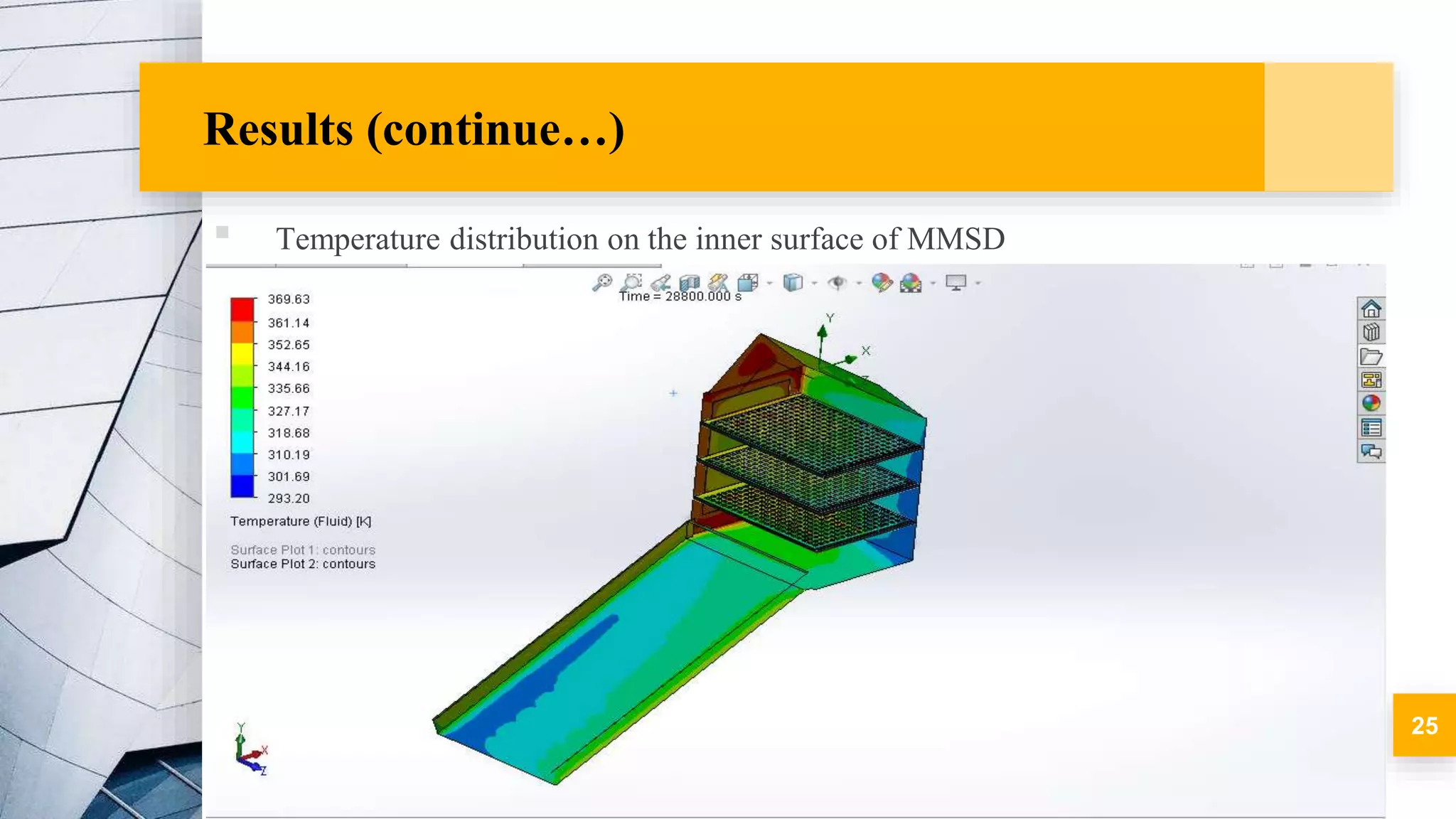

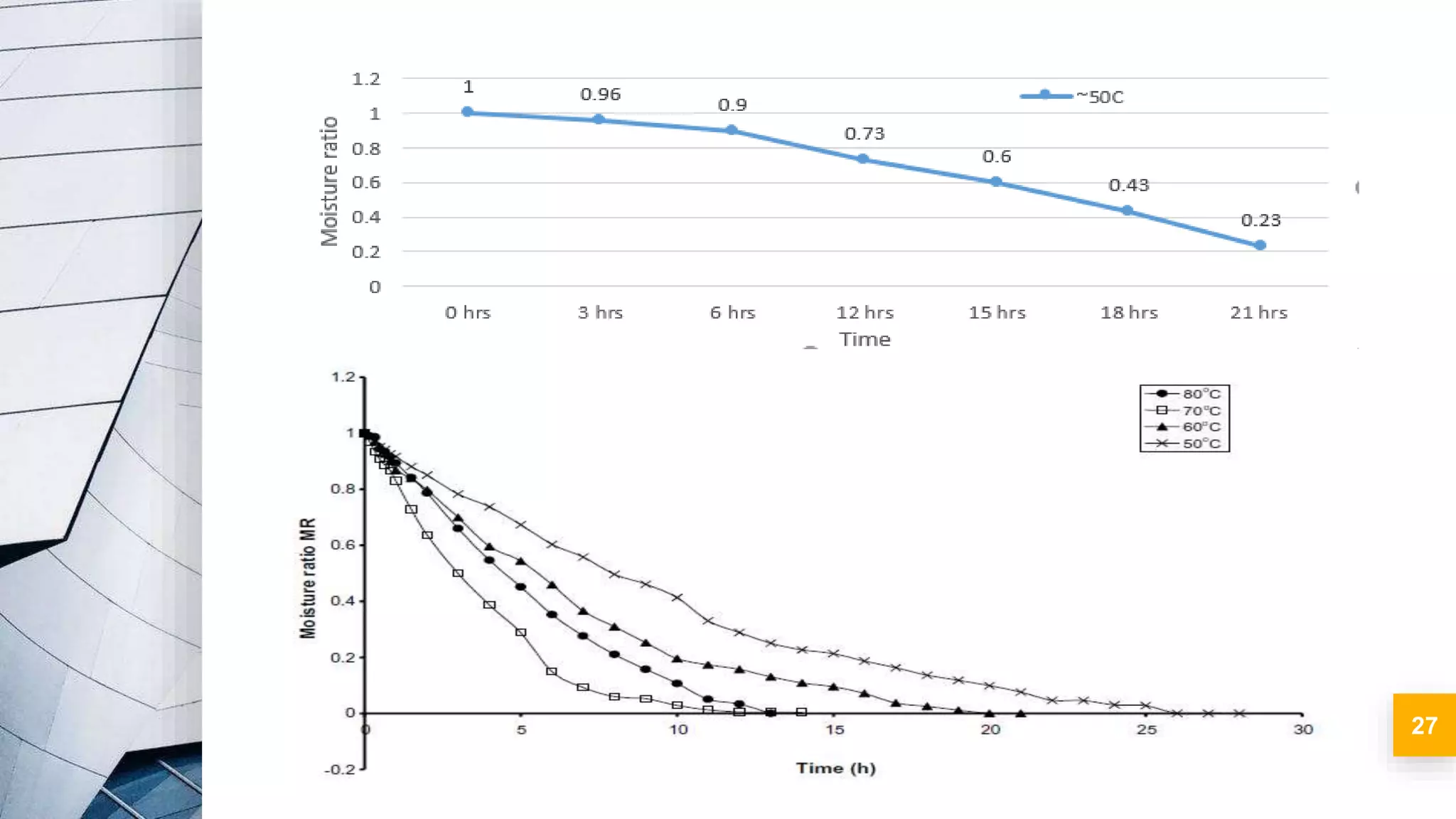

The document discusses the design, fabrication, and simulation of a mixed mode solar dehydrator specifically for drying dates in Khairpur district, Pakistan. It outlines the advantages of using solar drying over traditional methods, including reduced moisture loss and improved product quality. The research concludes that the mixed mode solar dehydrator is more efficient and requires less drying time compared to conventional drying methods.