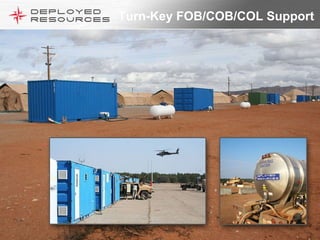

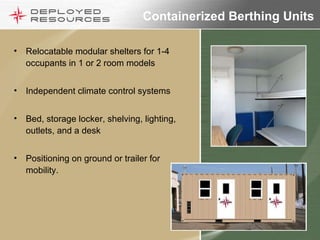

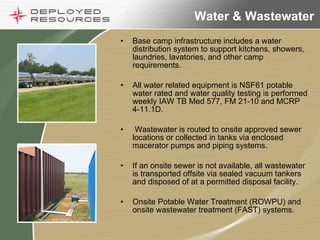

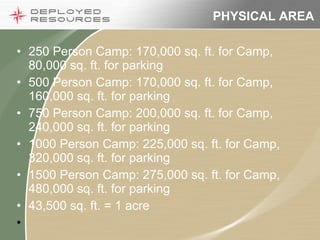

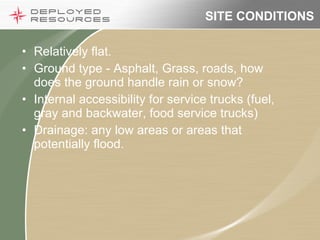

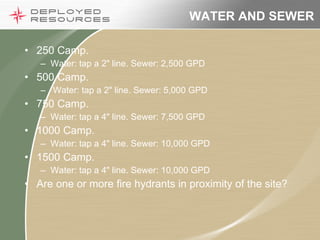

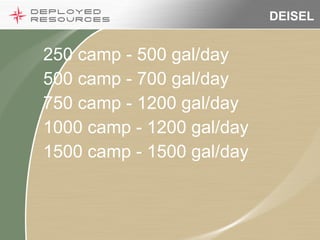

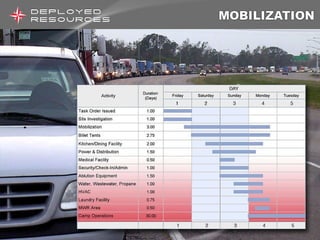

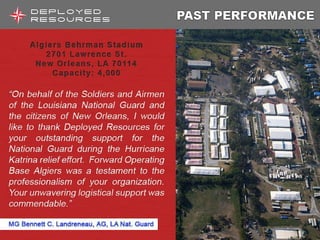

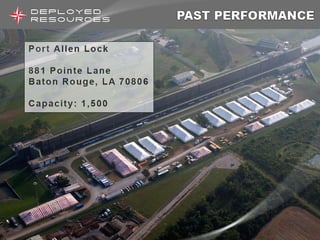

The document discusses turn-key responder base camps that can provide facilities and services for emergency responders during disasters. These include fully equipped camps with food service, showers, laundry, restrooms, water and power systems, billeting accommodations, and operations centers. The camps are designed to be rapidly deployable, self-sufficient, and have minimal environmental impact during setup and takedown. Specific requirements and logistics are outlined for planning camps that can support between 250-1500 personnel.