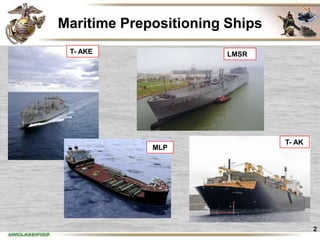

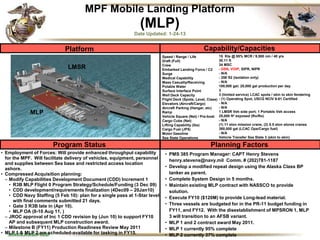

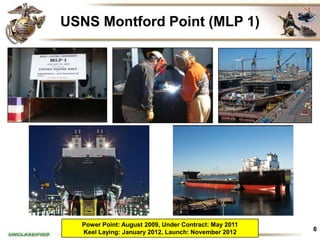

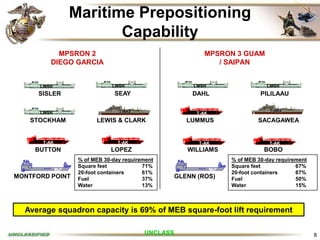

The document discusses the U.S. Marine Corps' maritime prepositioning ships and strategy. It outlines plans to enhance capabilities through the use of roll-on/roll-off cargo ships coupled with mobile landing platforms. These platforms will provide increased throughput and selective offload capabilities. The mobile landing platform is described as providing vehicle transfer between prepositioning ships and shore via landing craft air cushion vehicles. The first mobile landing platform, the USNS Montford Point, is discussed as being near completion.