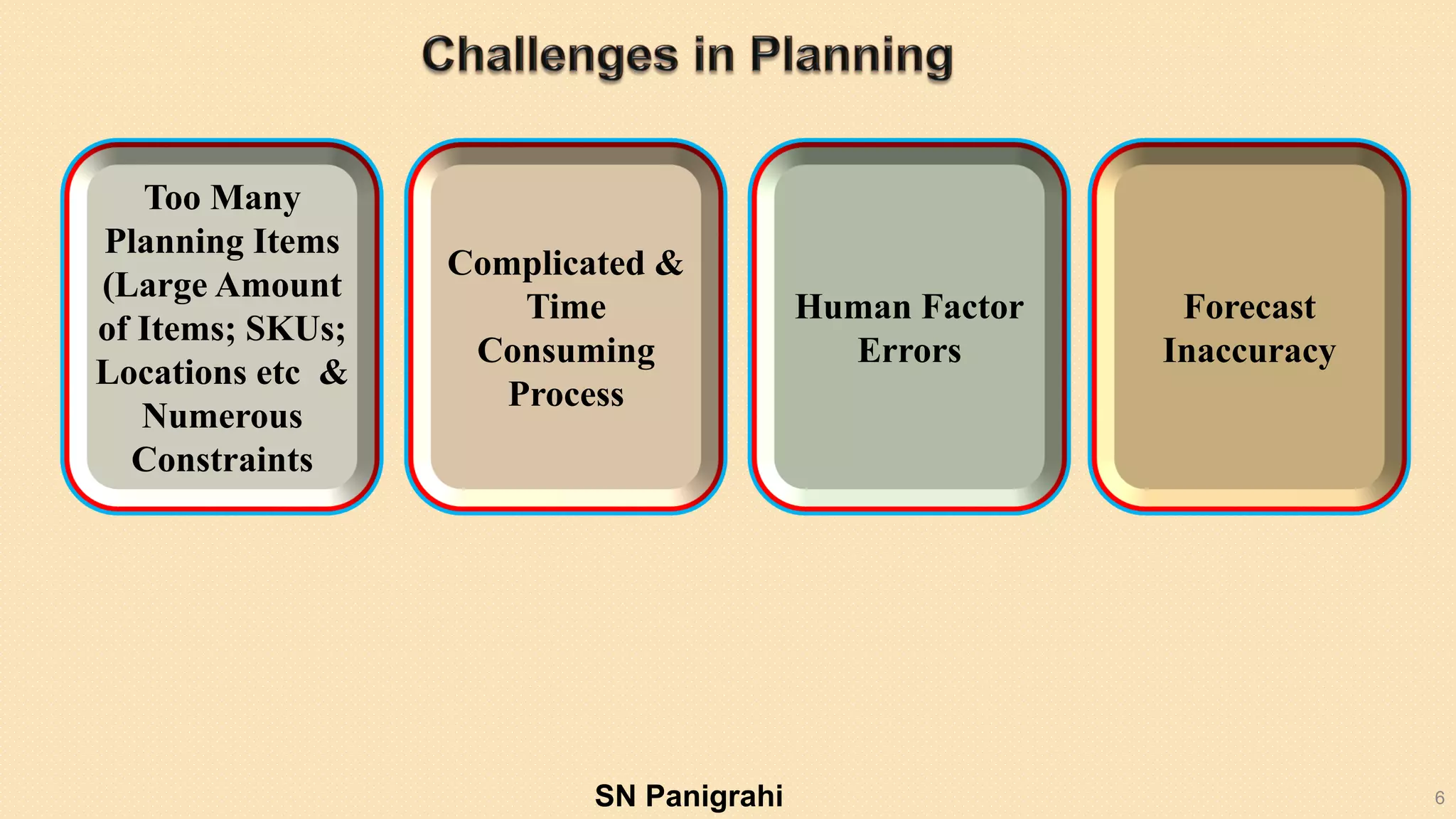

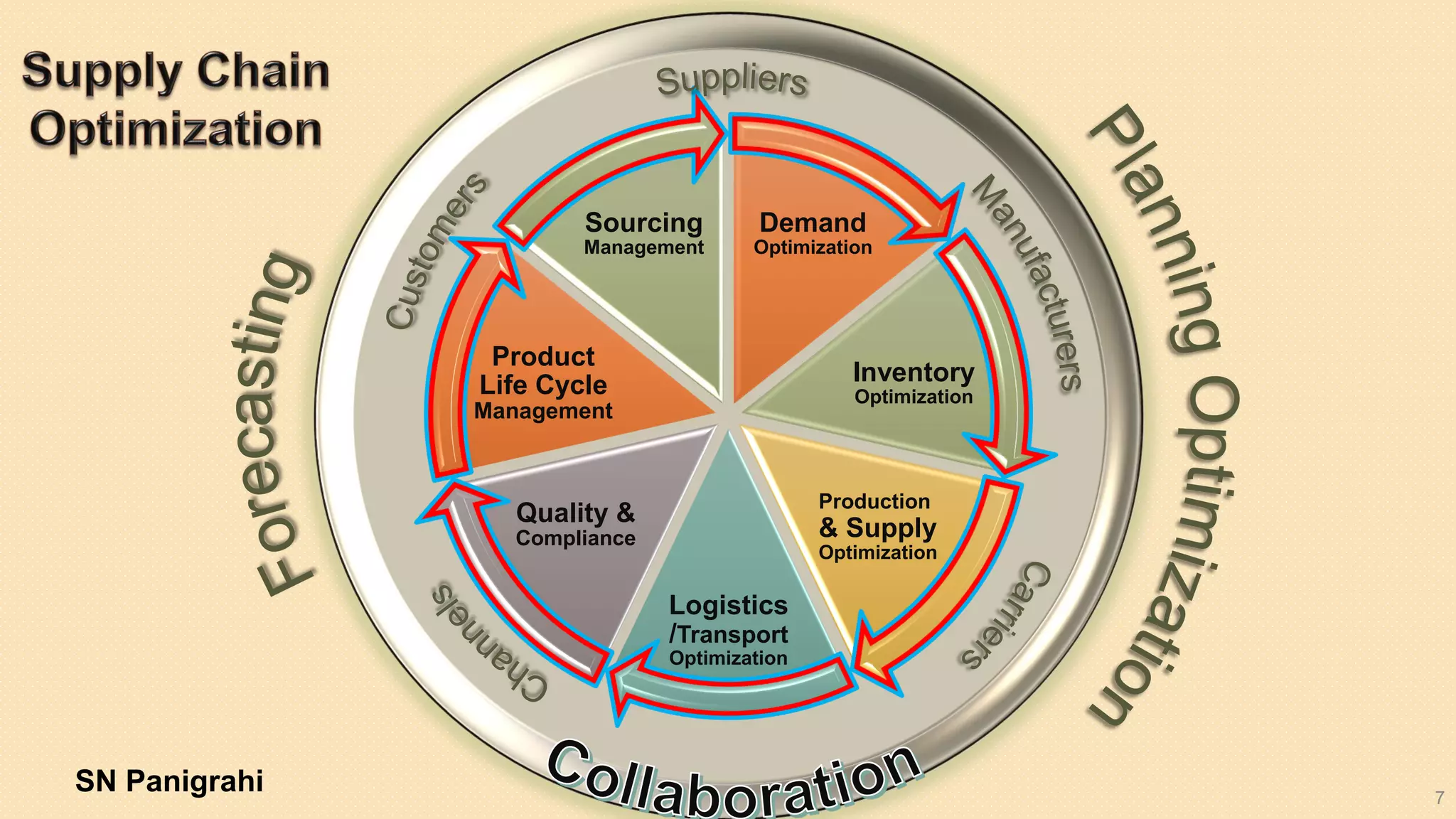

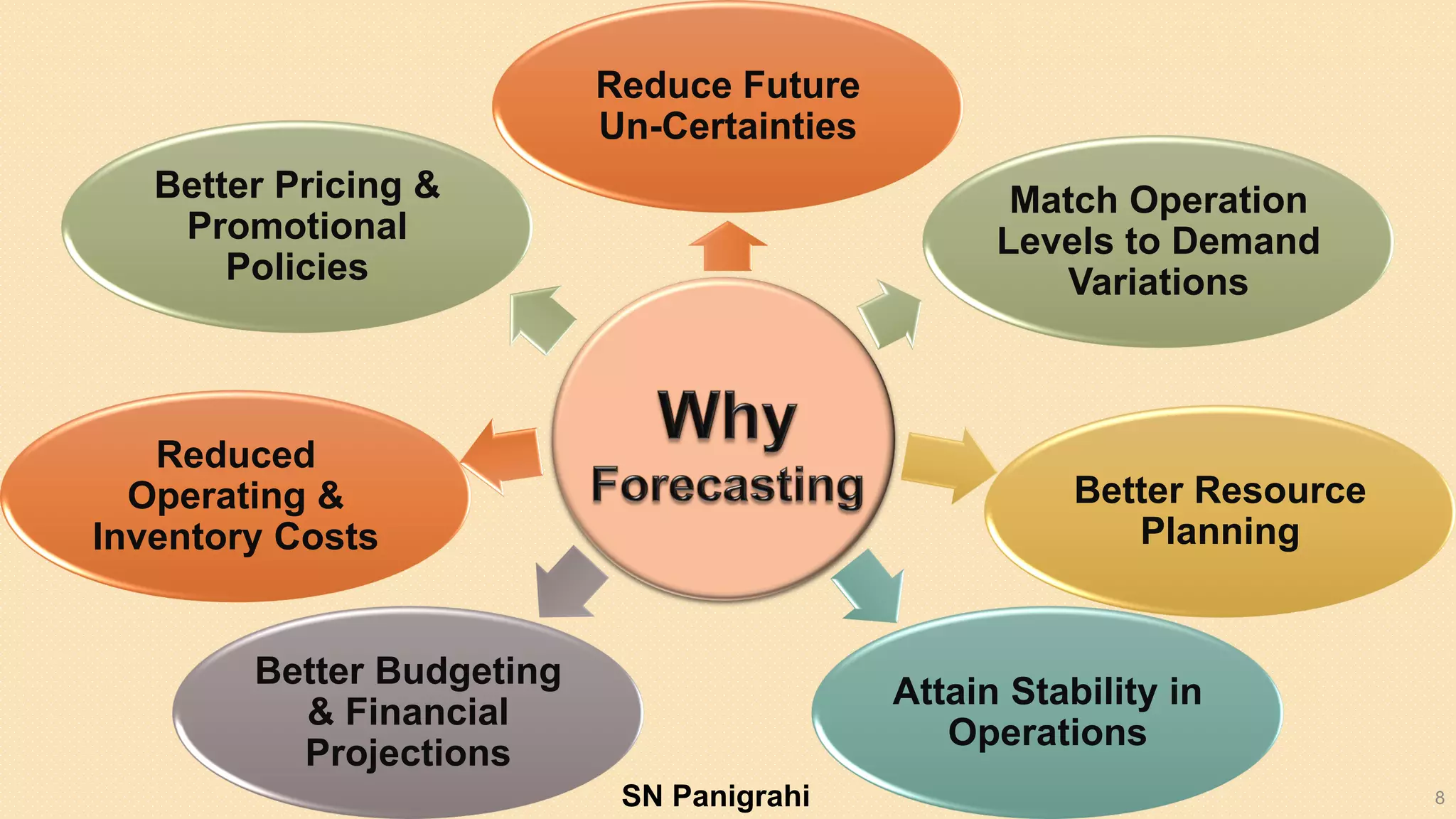

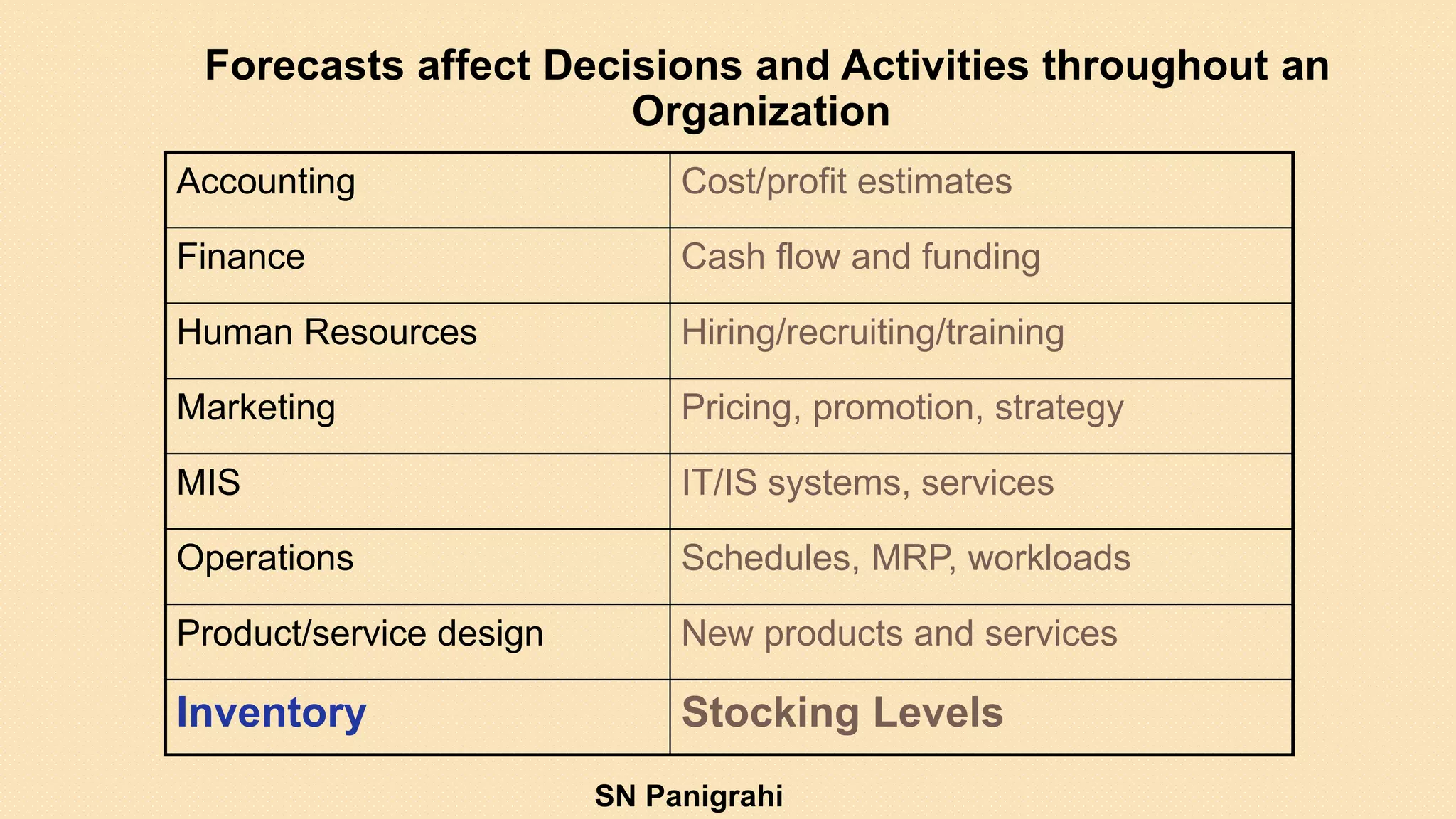

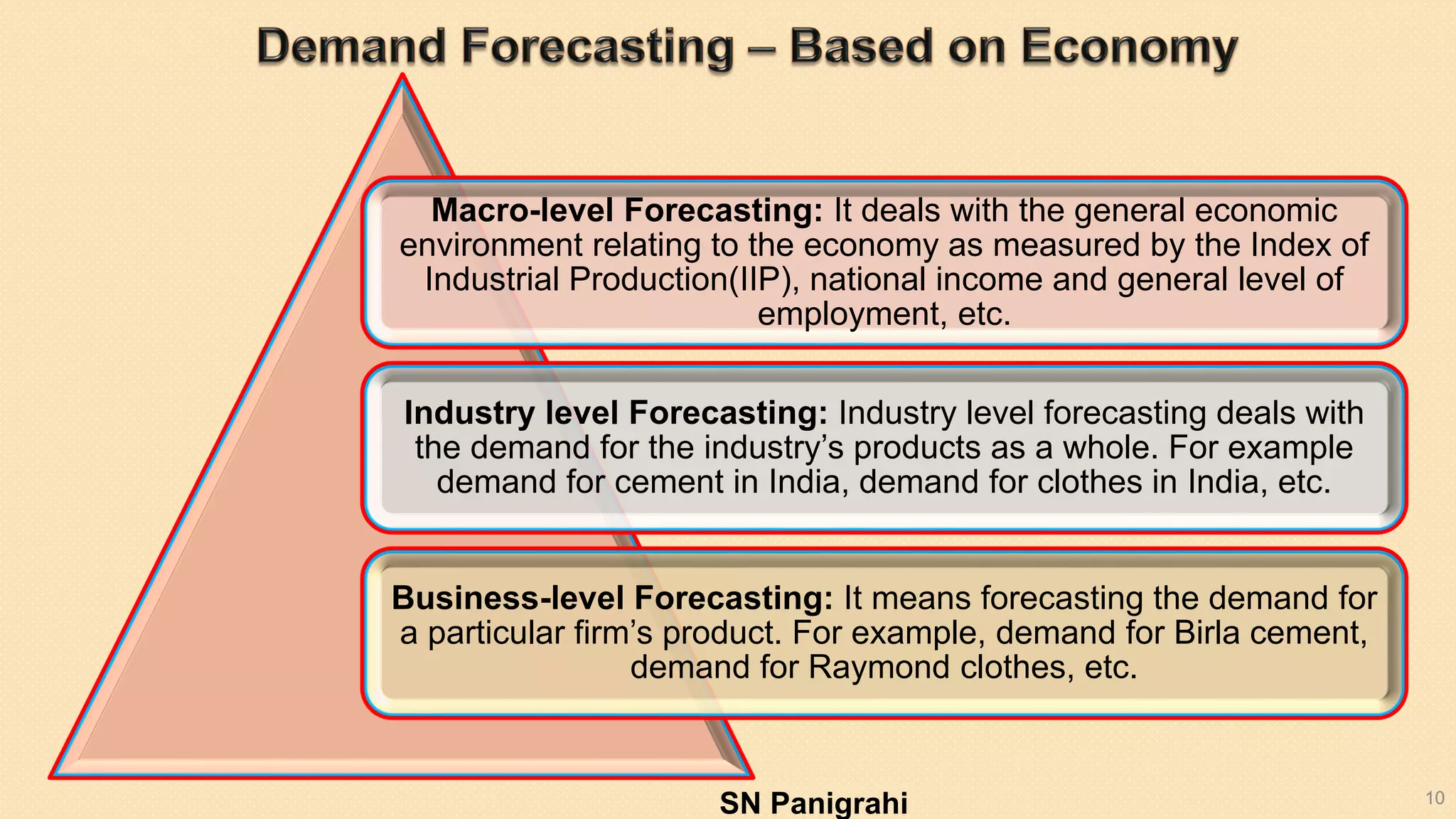

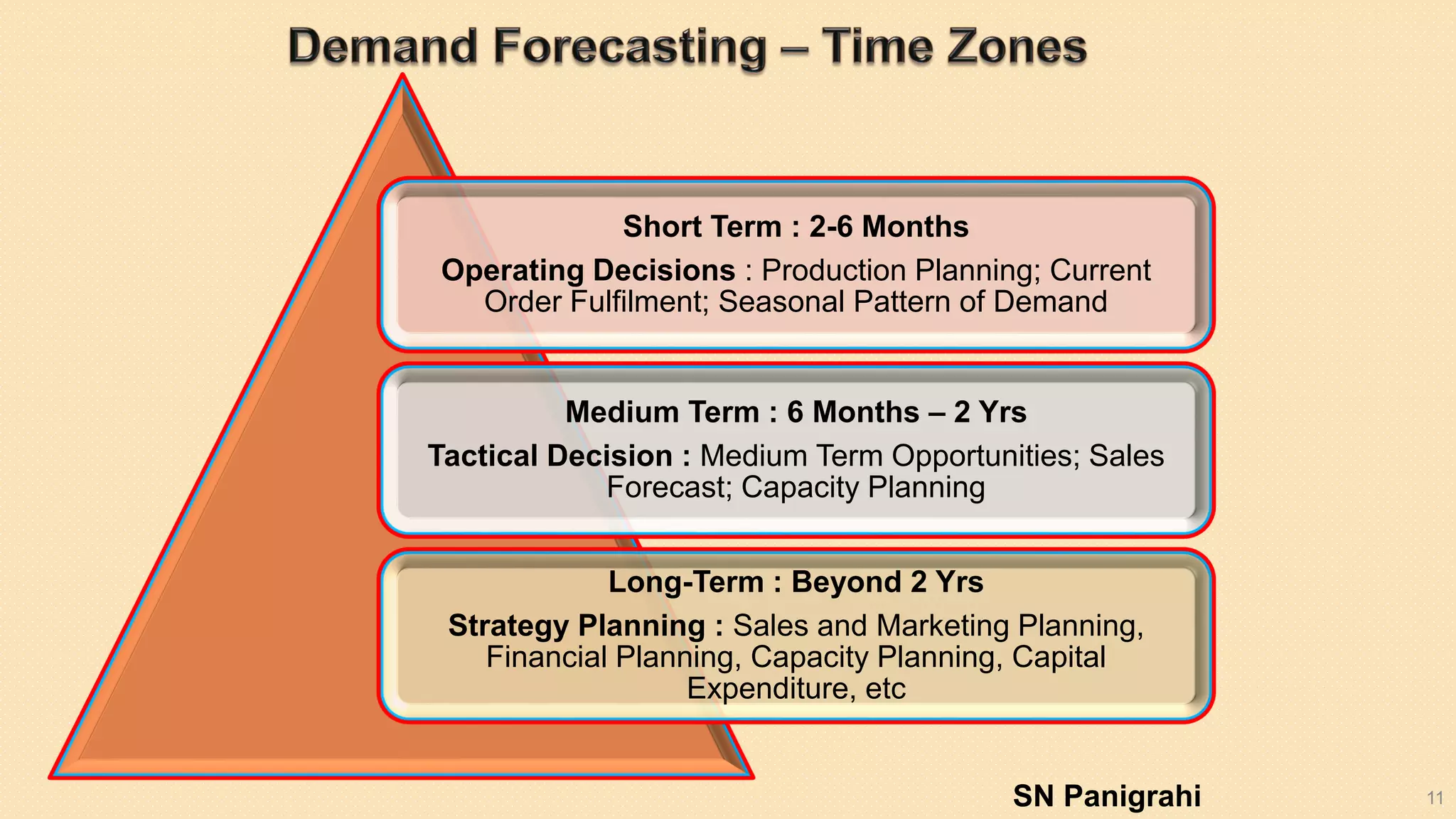

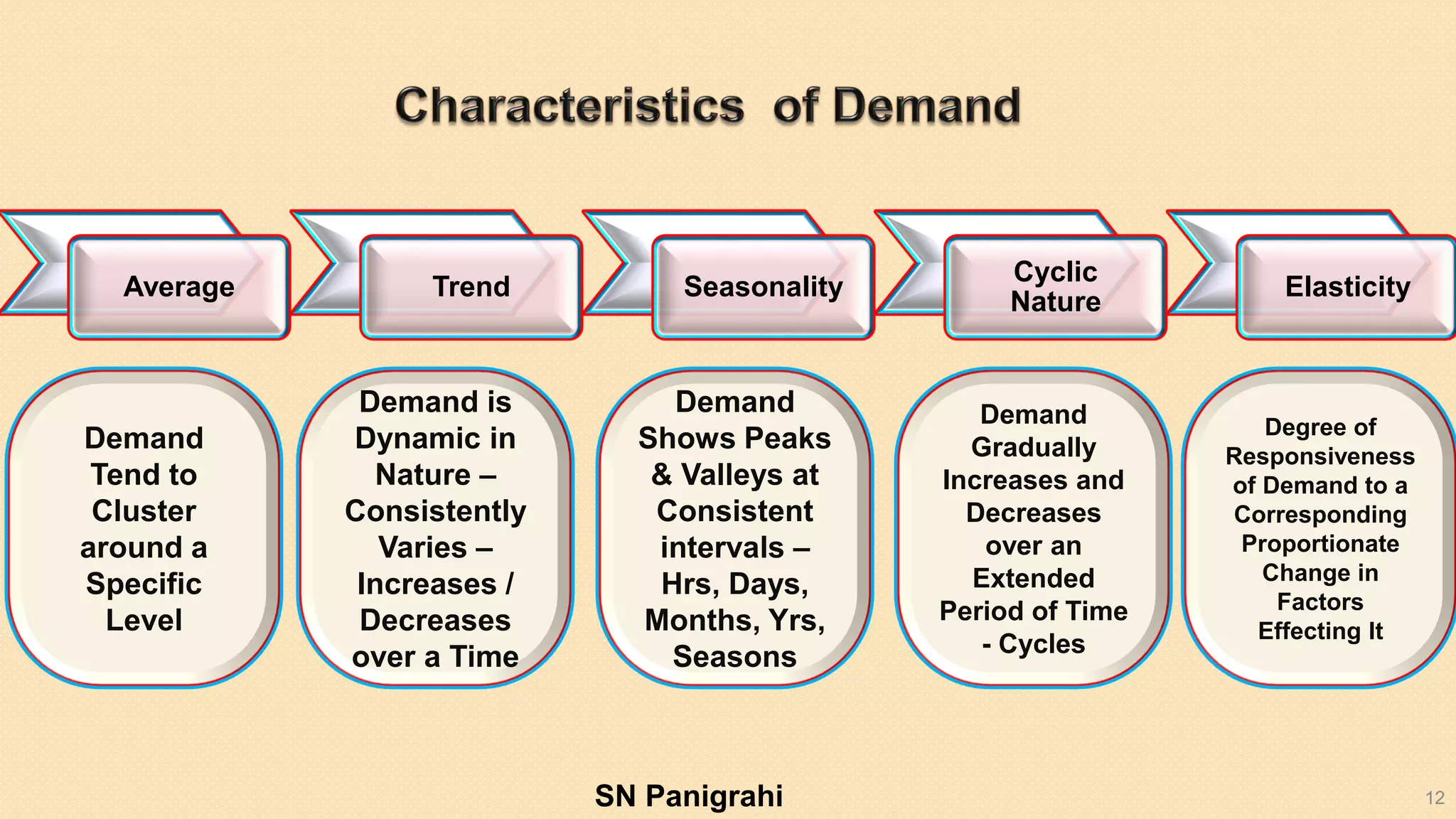

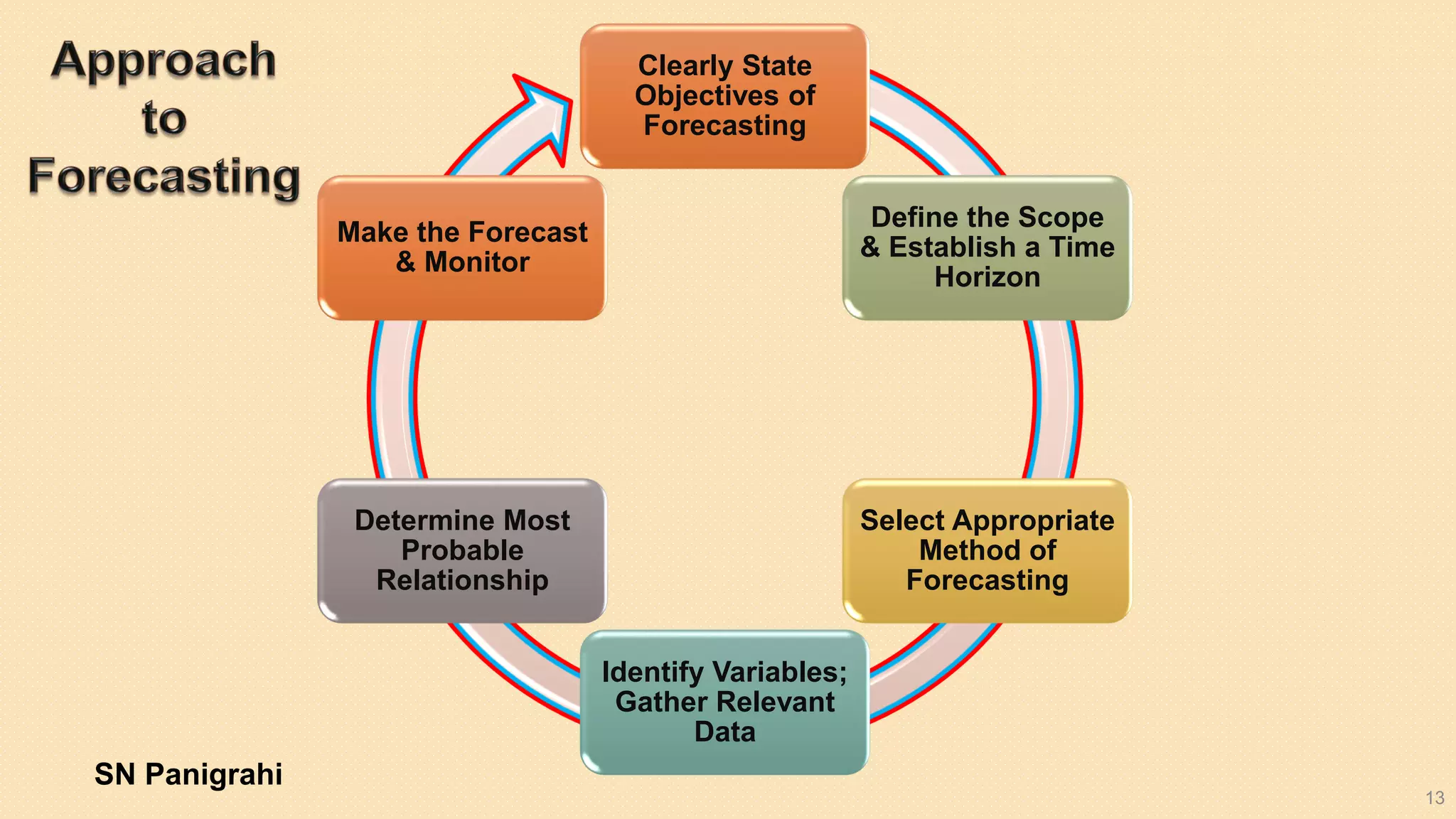

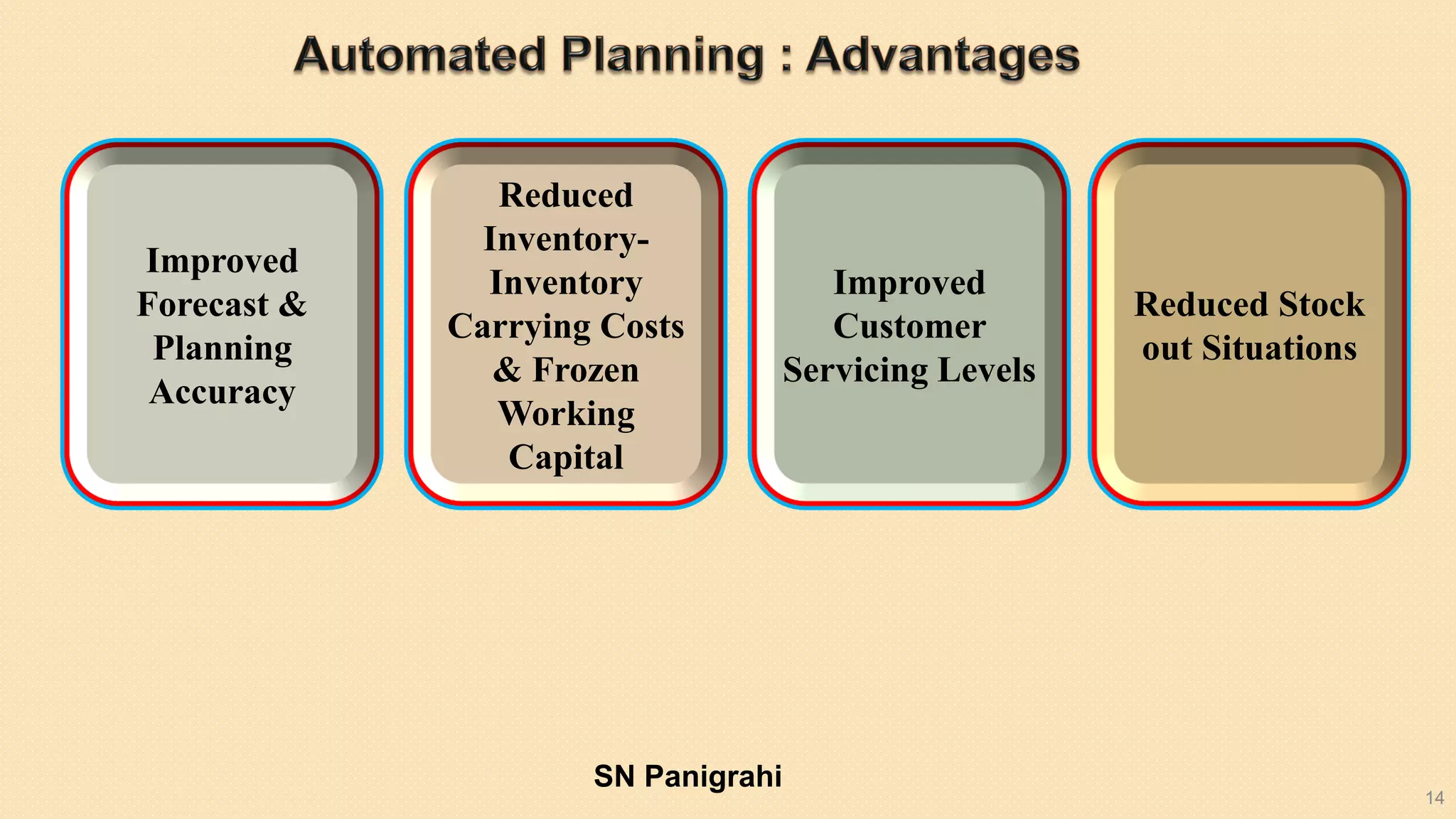

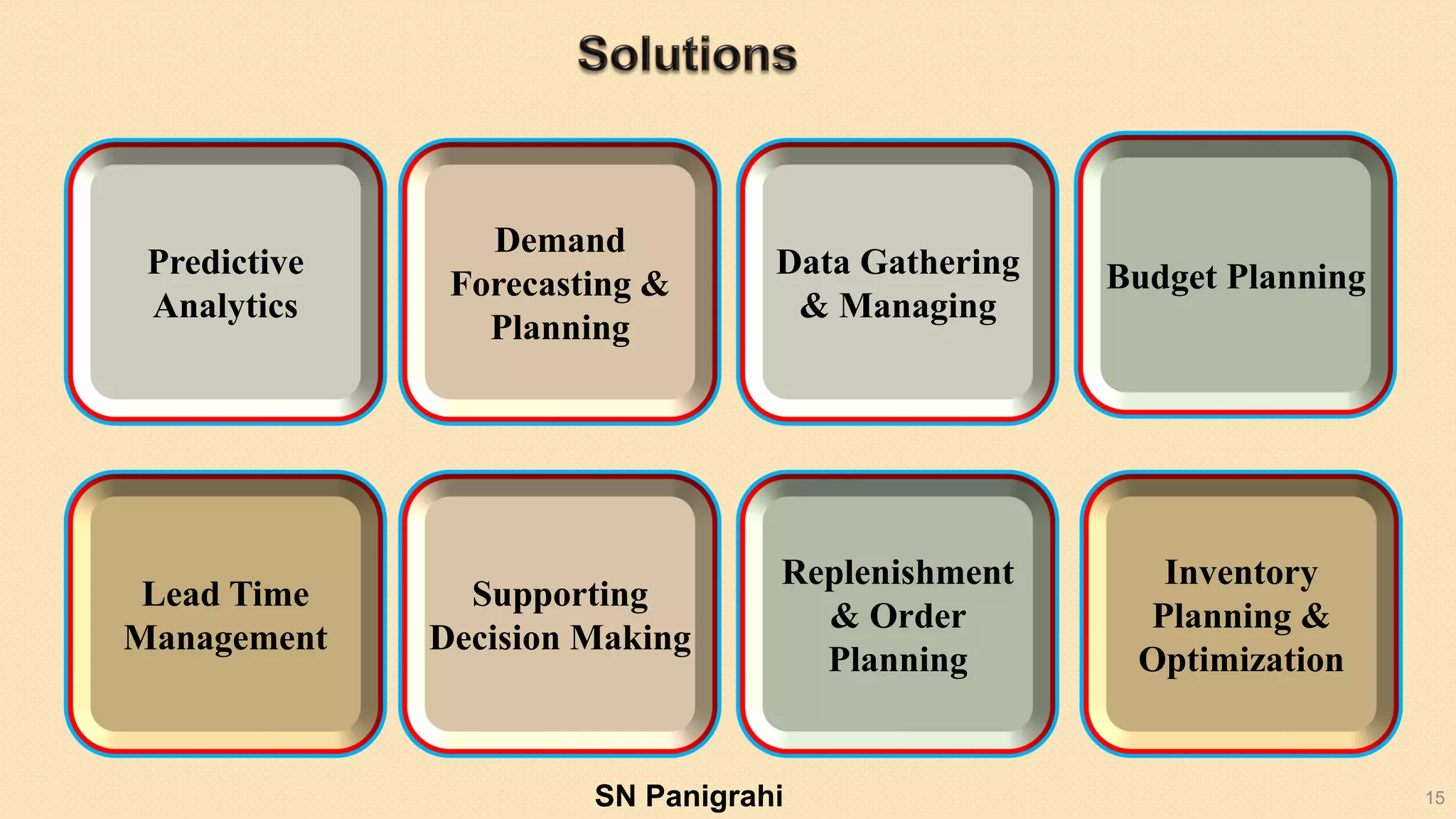

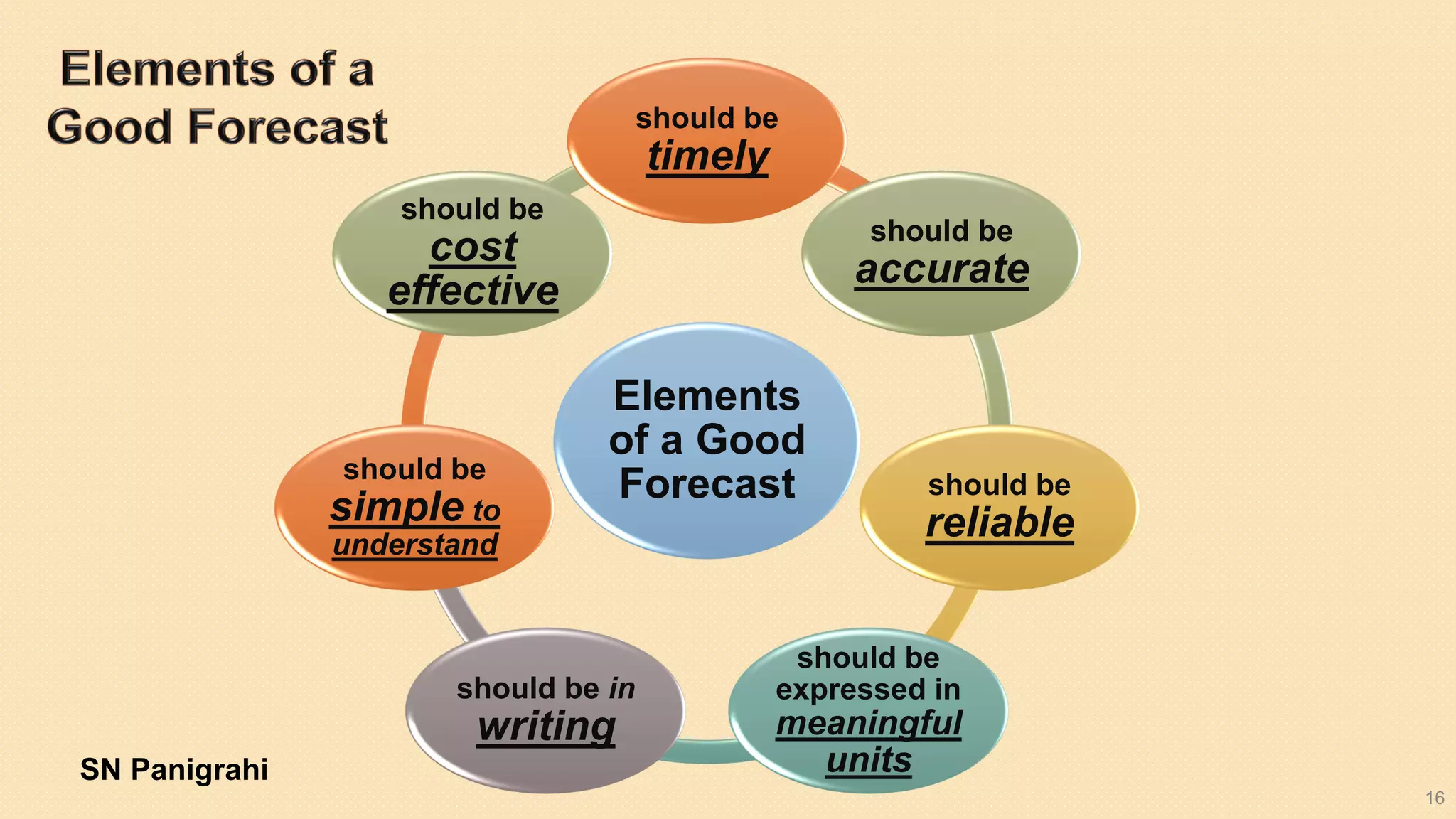

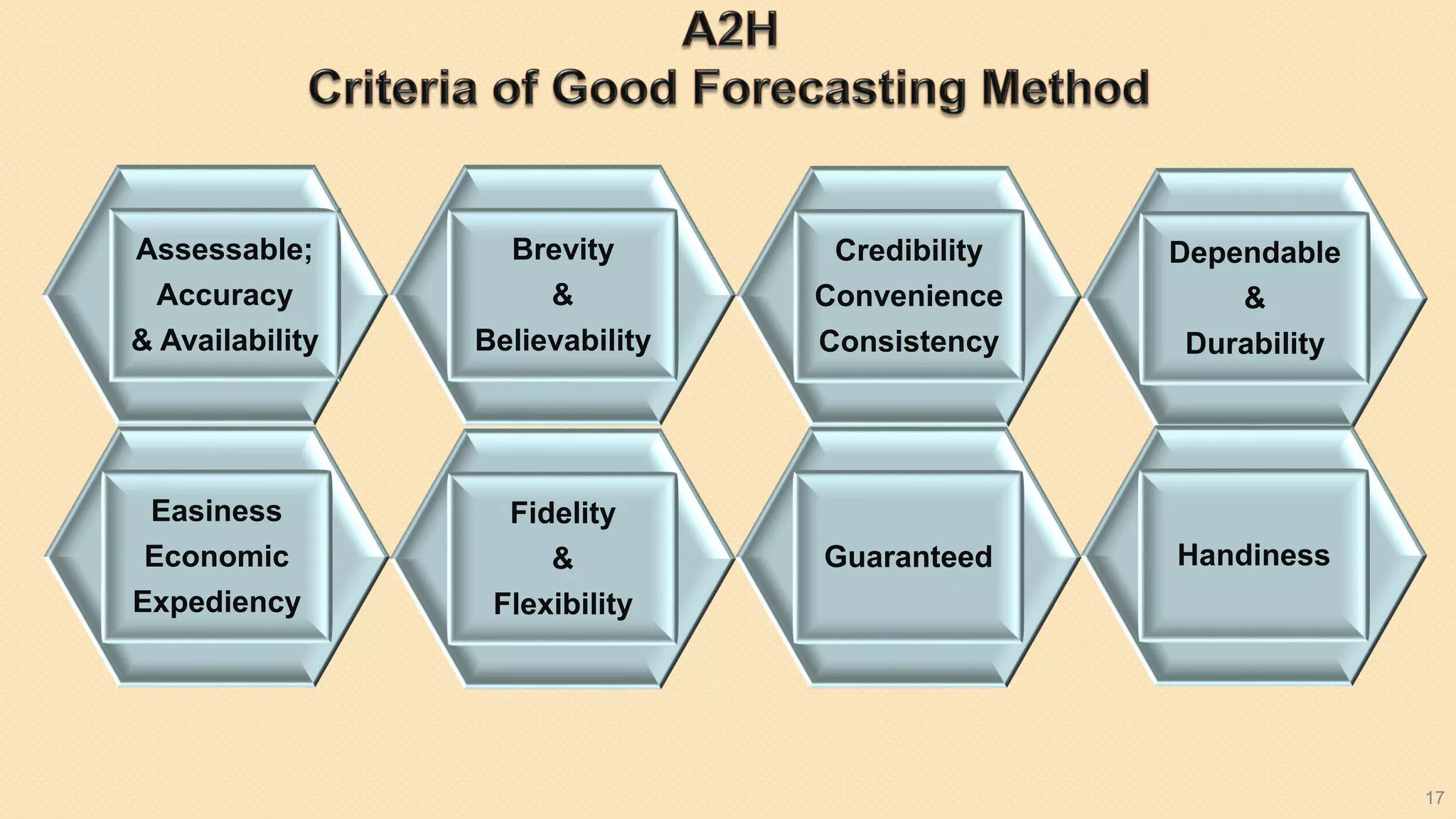

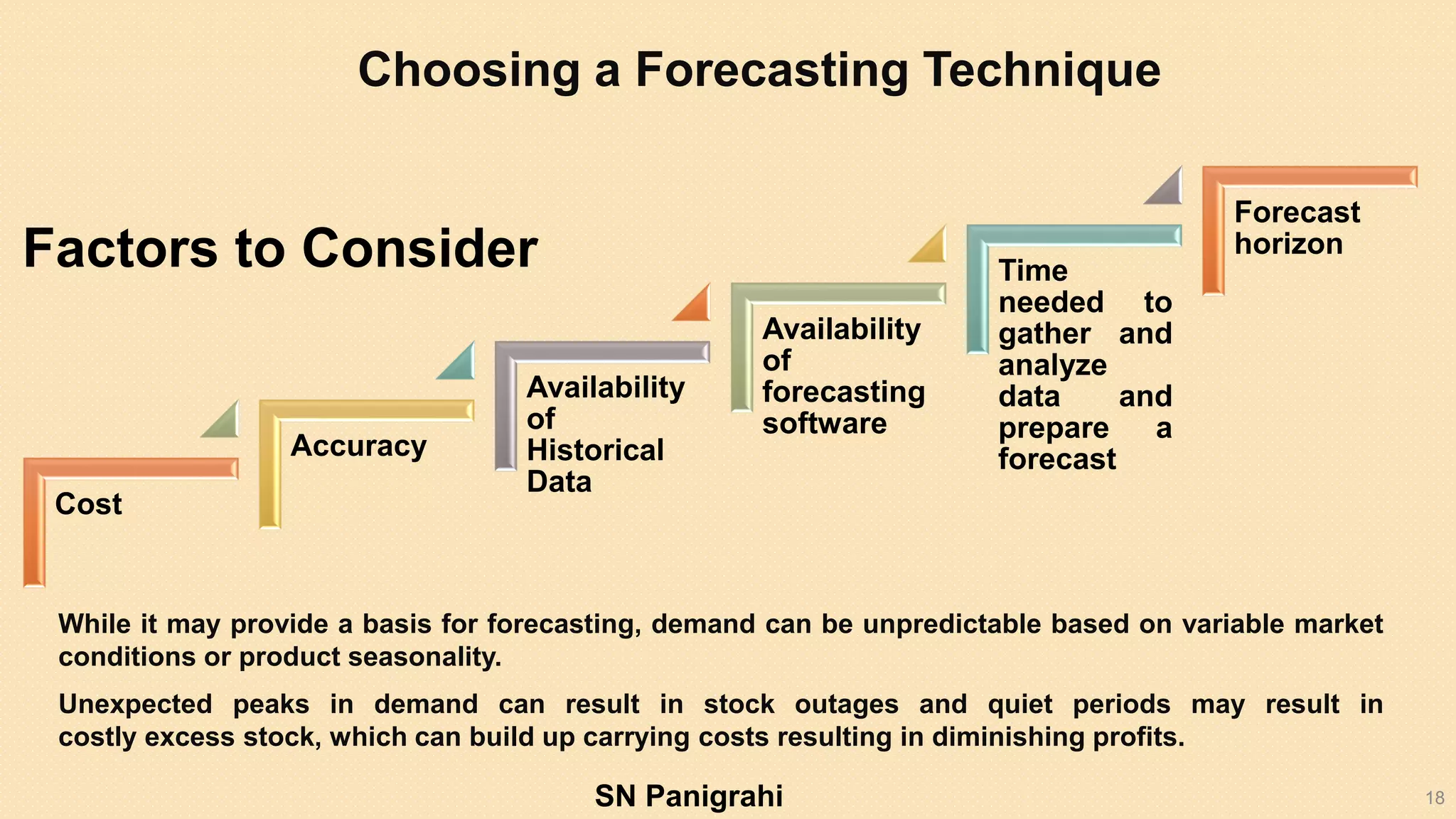

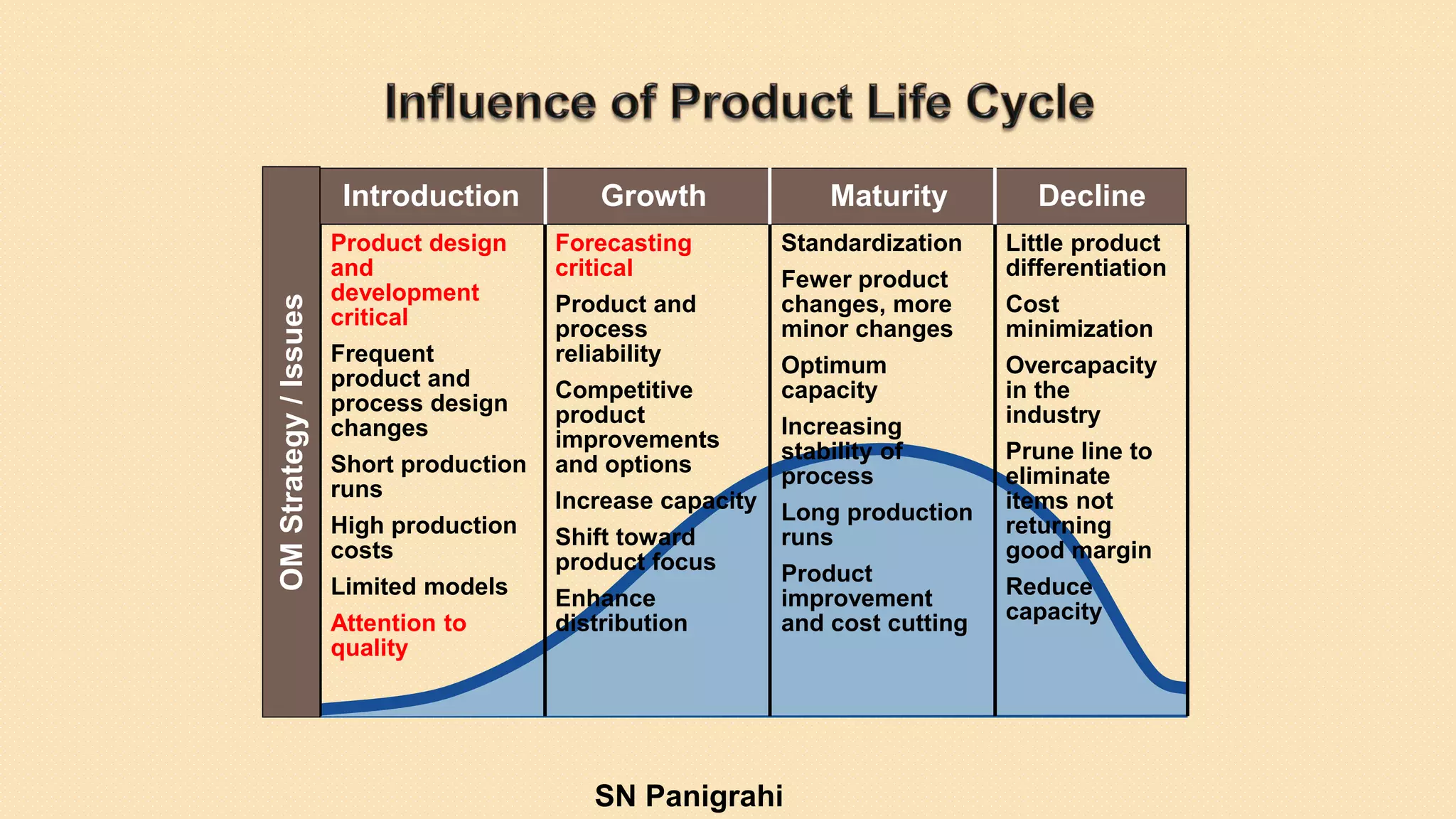

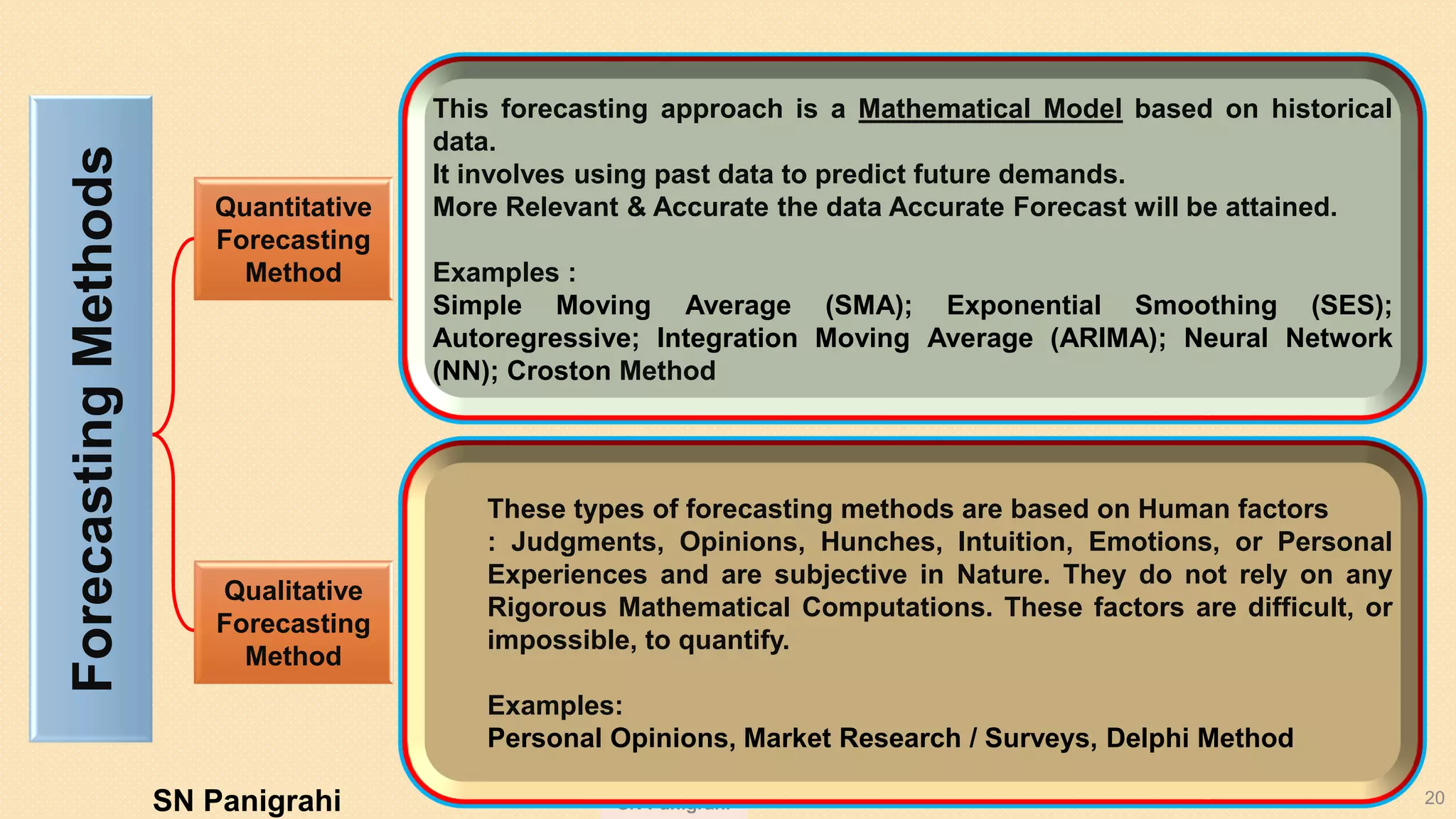

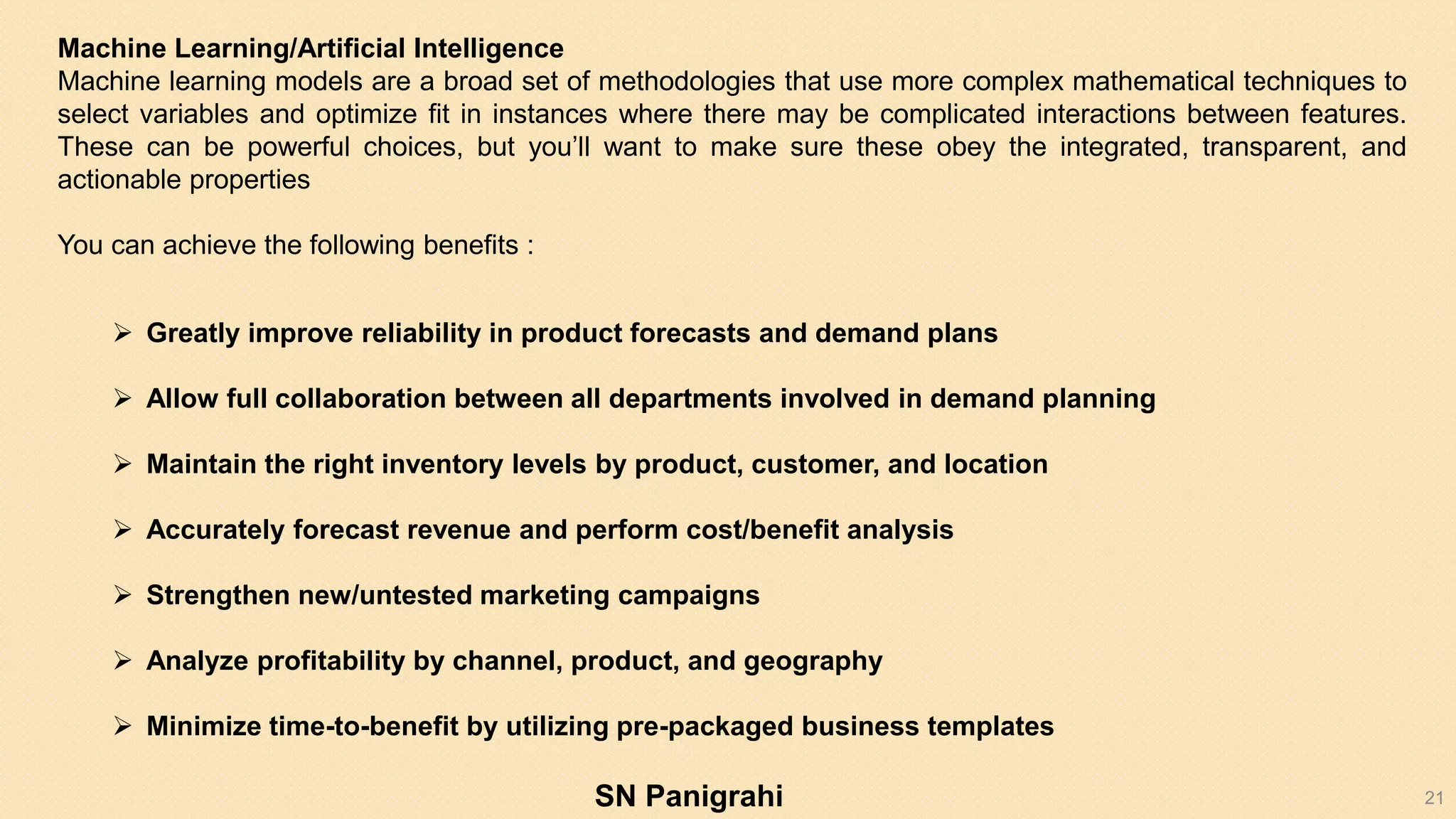

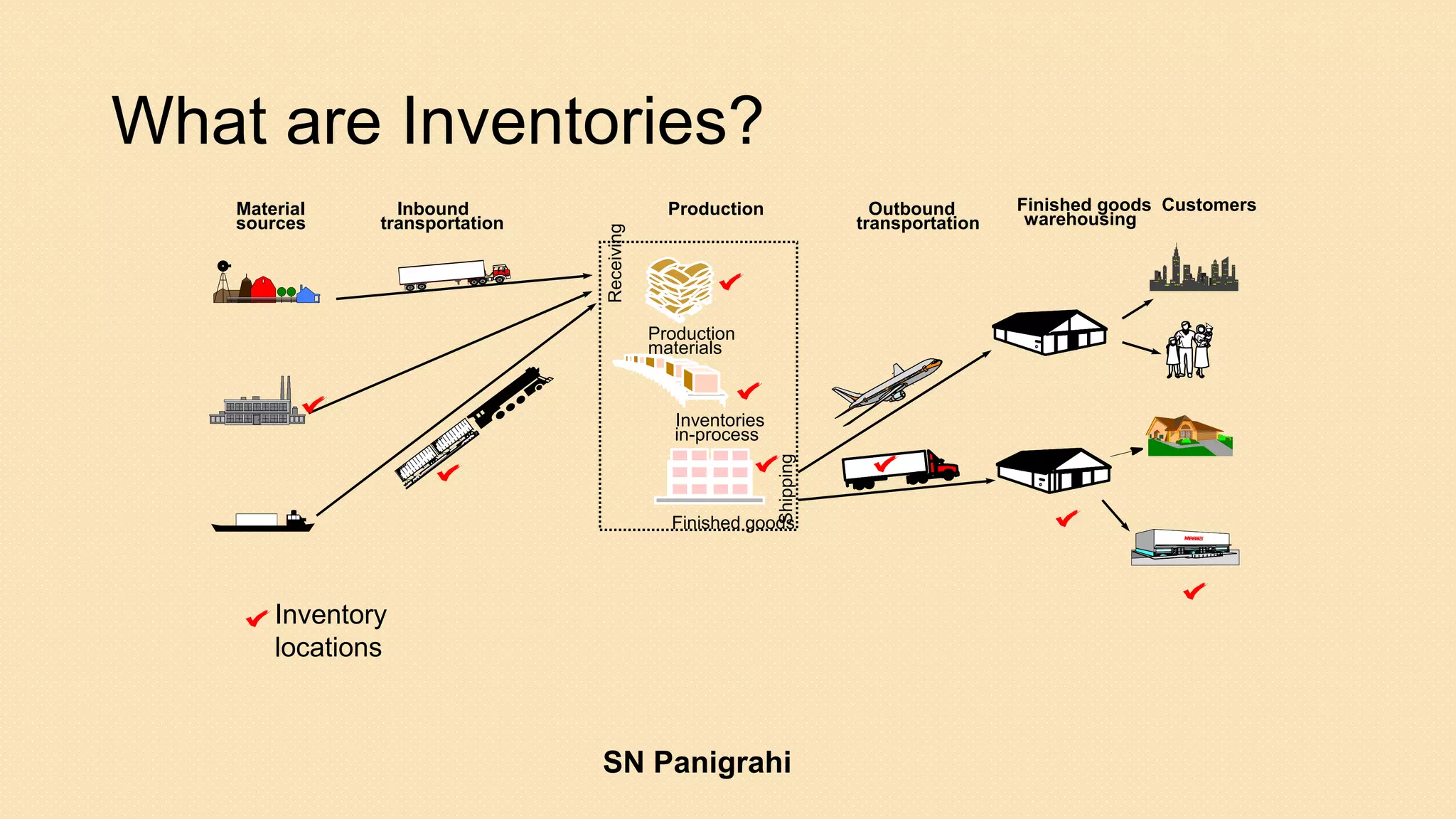

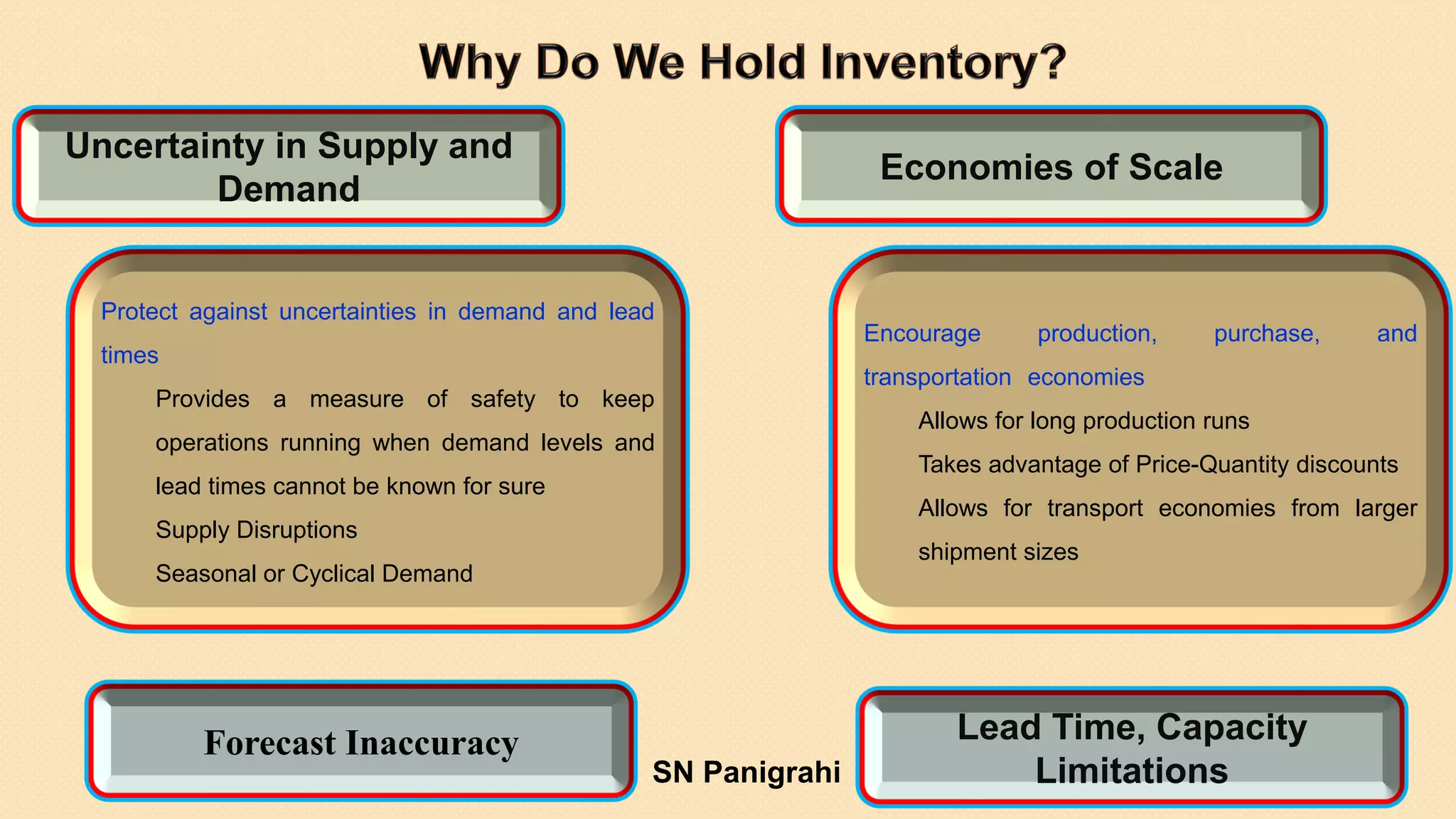

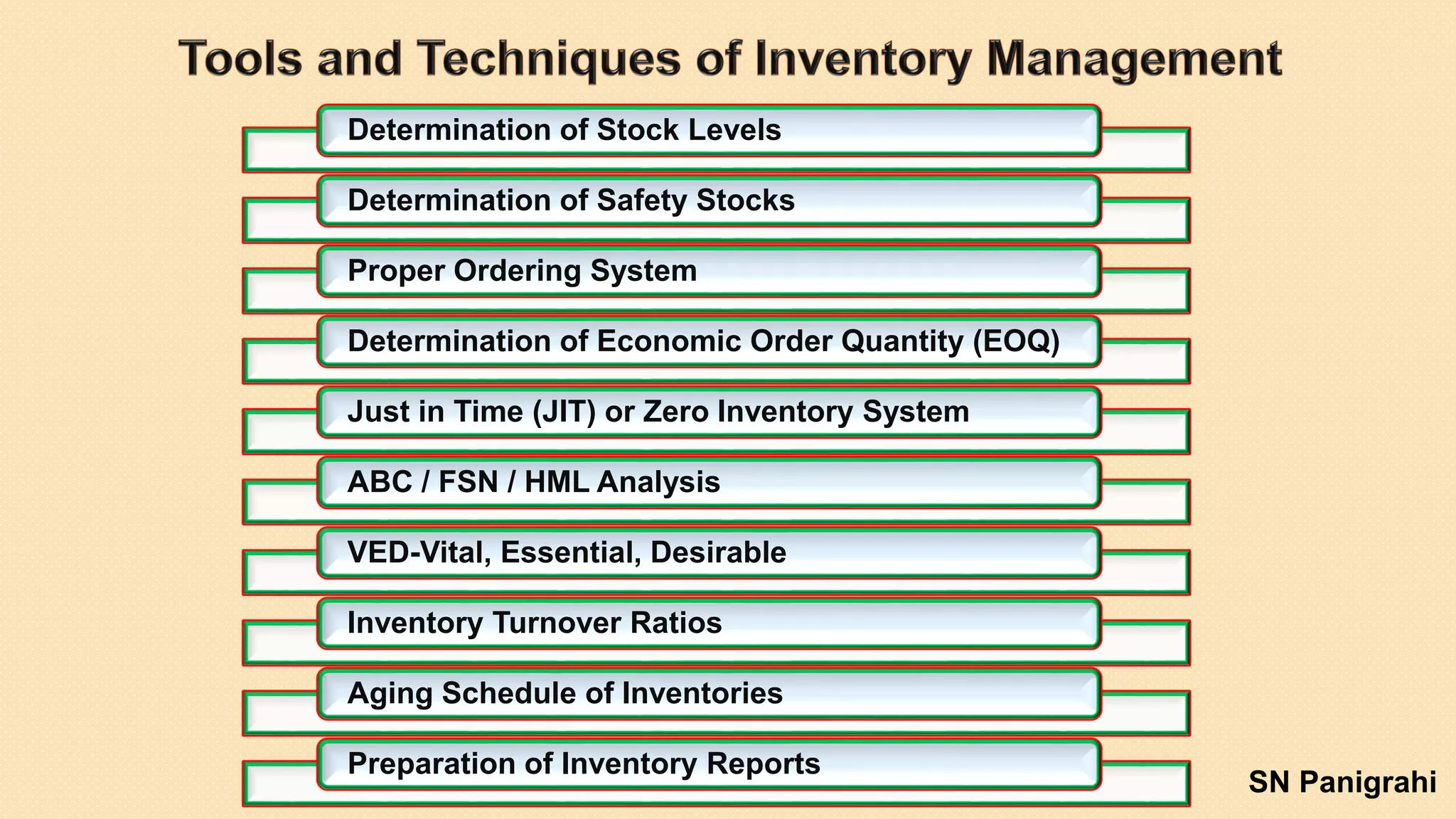

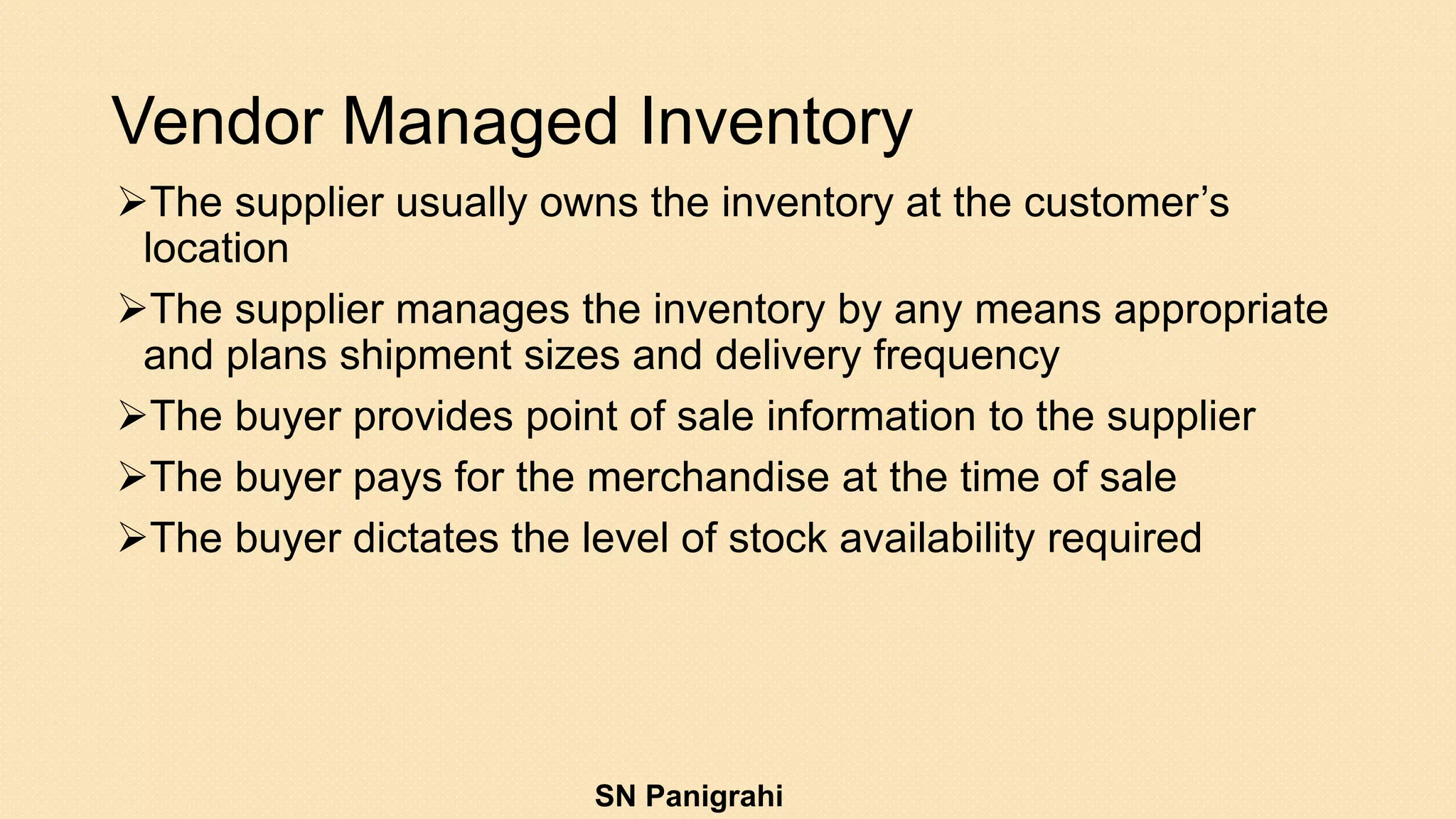

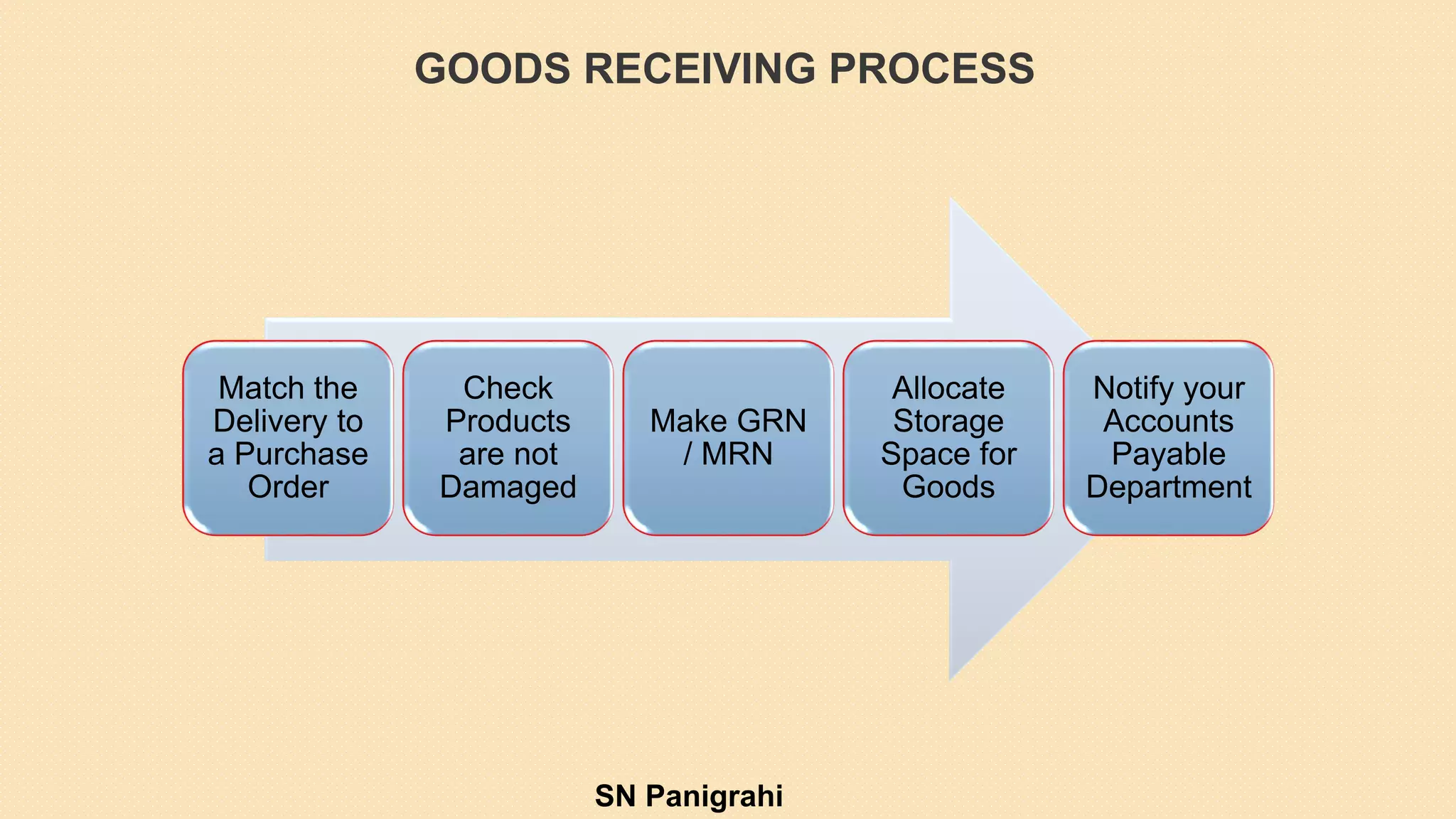

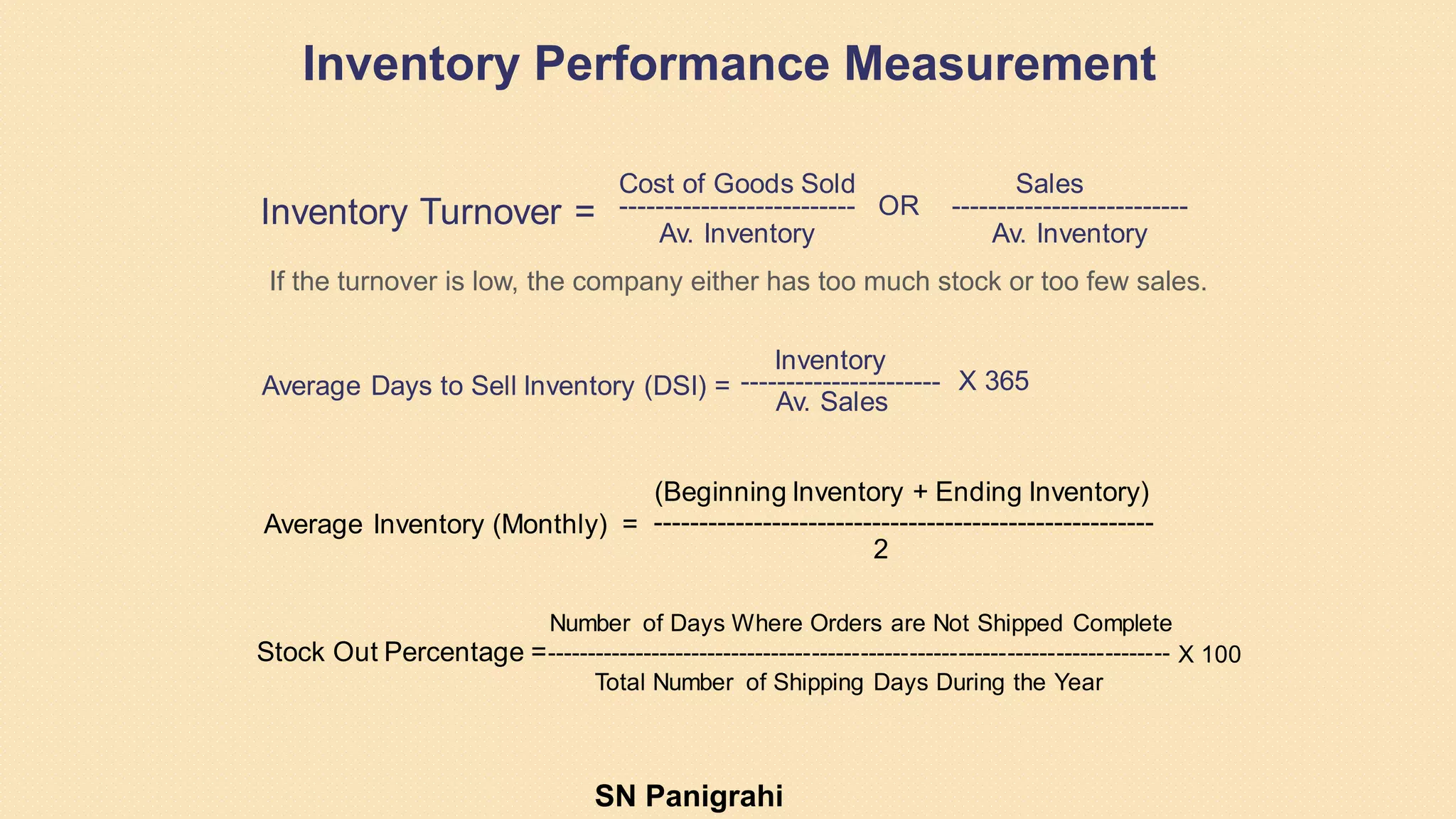

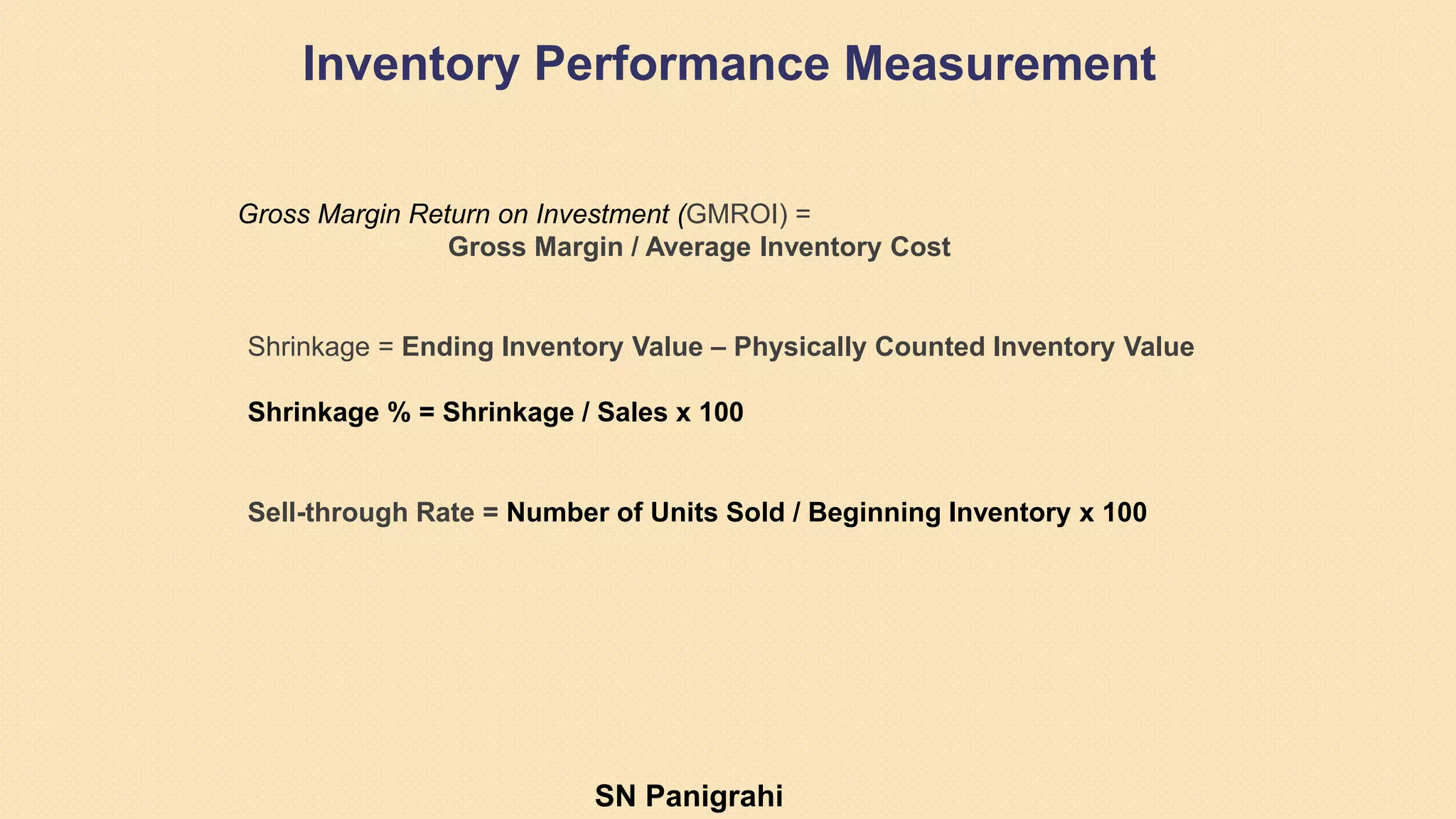

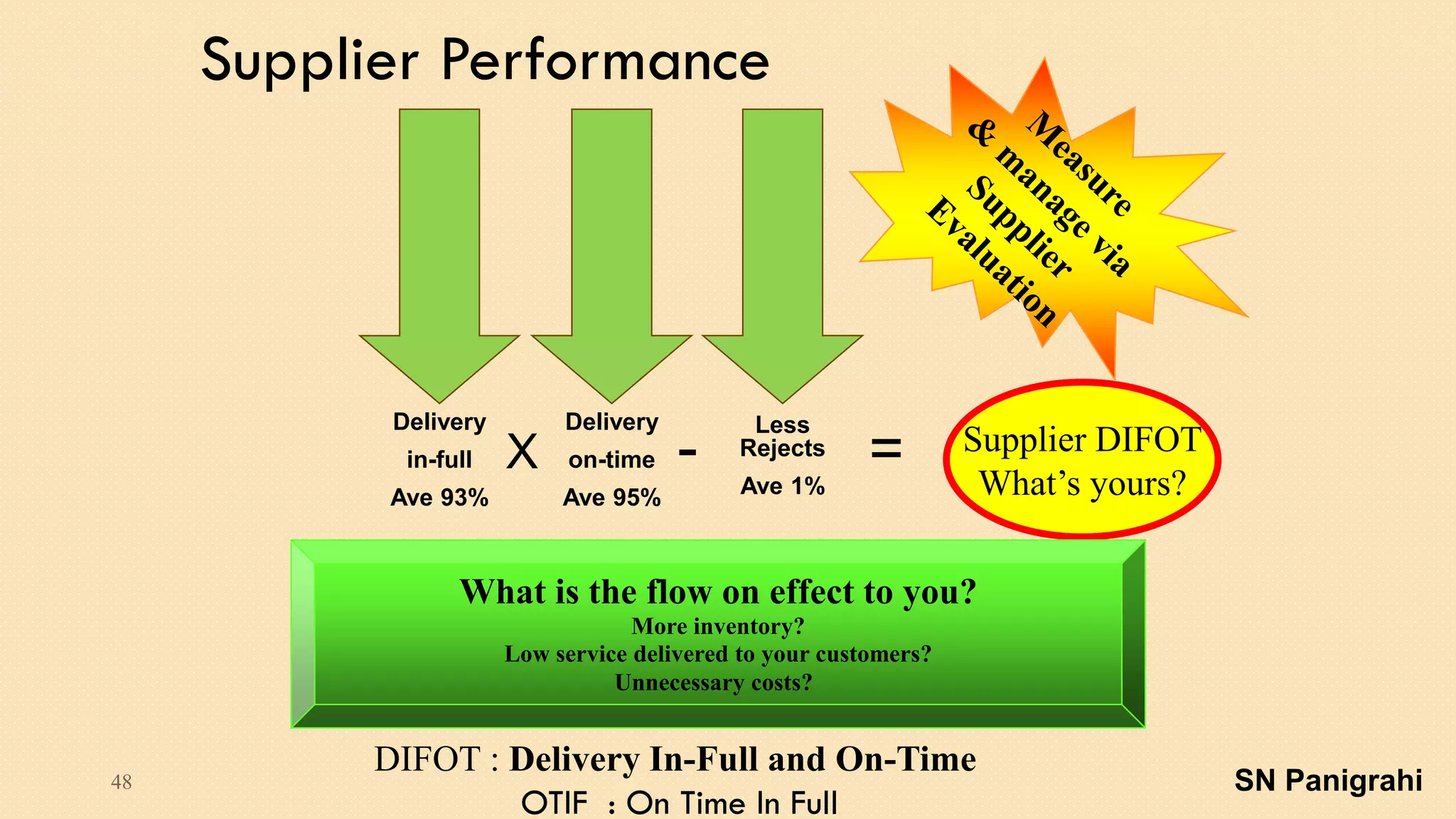

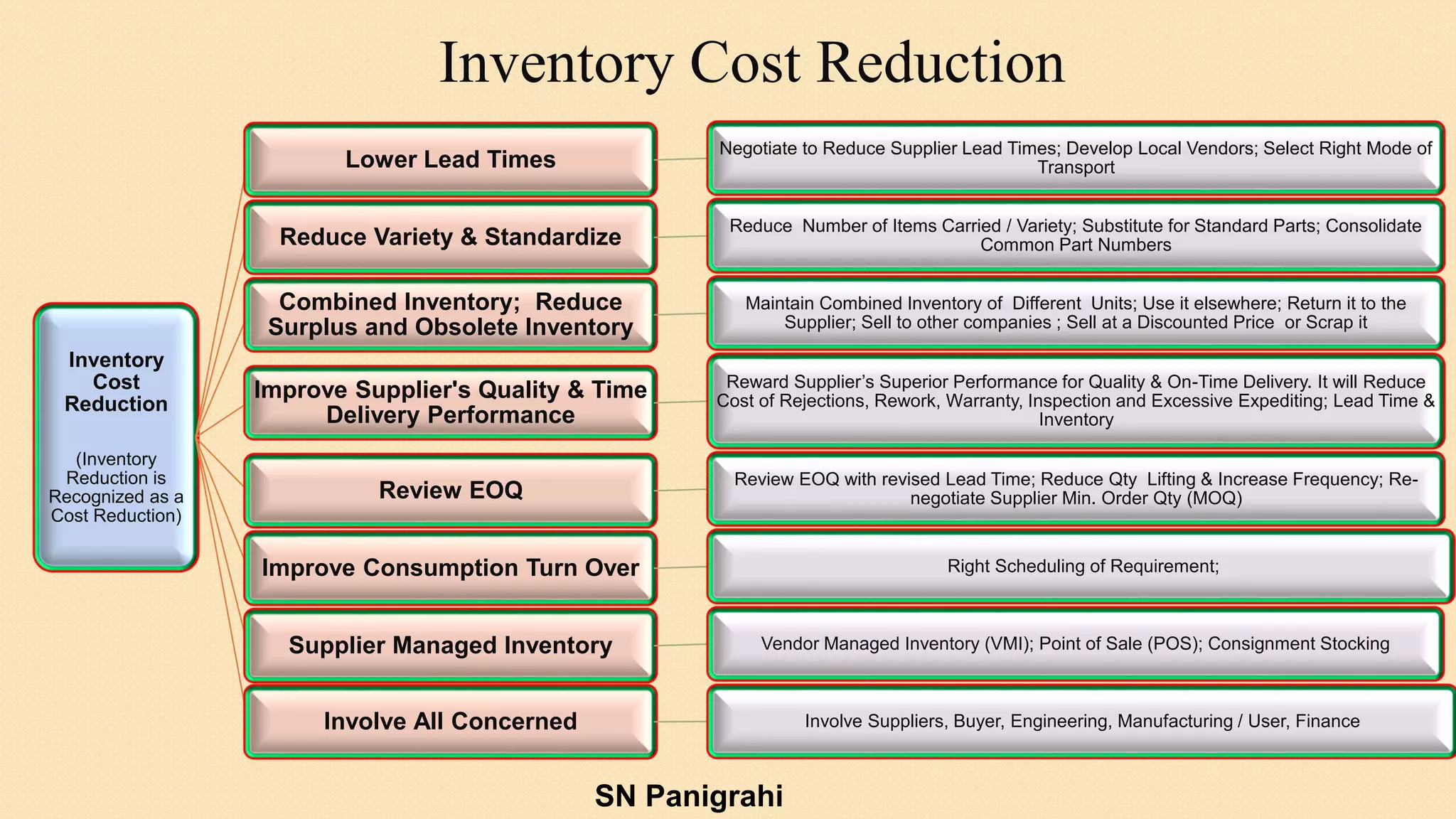

SN Panigrahi is a versatile expert with over 29 years of experience in various fields including project management, demand forecasting, and inventory optimization. The document outlines the significance of demand forecasting and planning in business operations, emphasizing its role in budgeting, resource planning, and optimizing supply chain processes. Additionally, it covers various forecasting methods, inventory management strategies, and cost reduction techniques to enhance organizational efficiency.