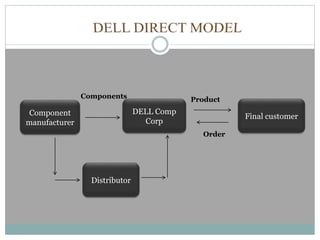

Dell utilizes a direct sales model that cuts out retailers. It takes customized orders directly from customers and uses an integrated supply chain model. Dell sources components from suppliers and uses revolving inventory models where suppliers share inventory warehouses. Dell monitors supplier performance and inventory levels closely through a scorecard system. It aims to deliver components and finished products within short timeframes to fulfill precise customer orders.