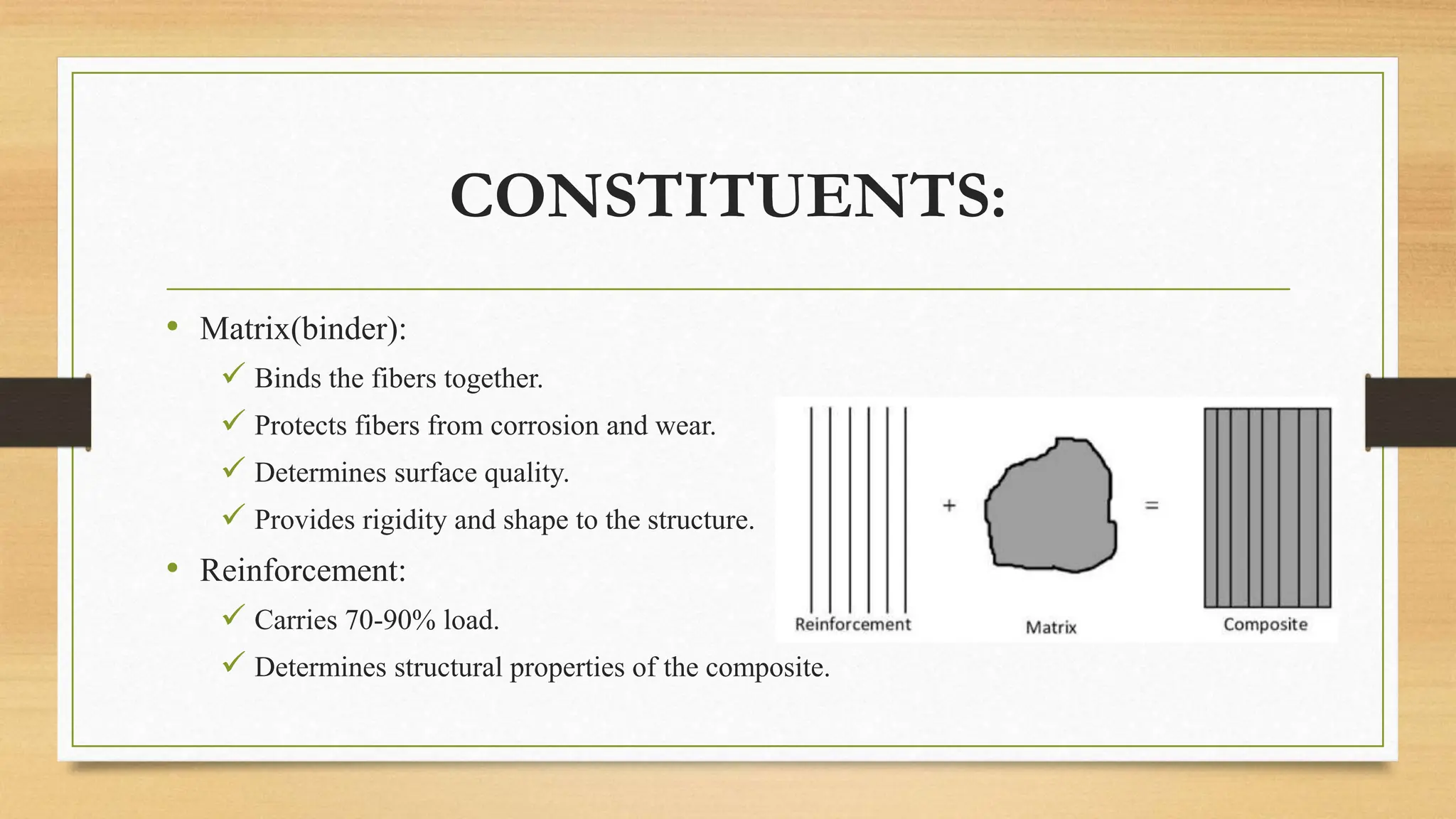

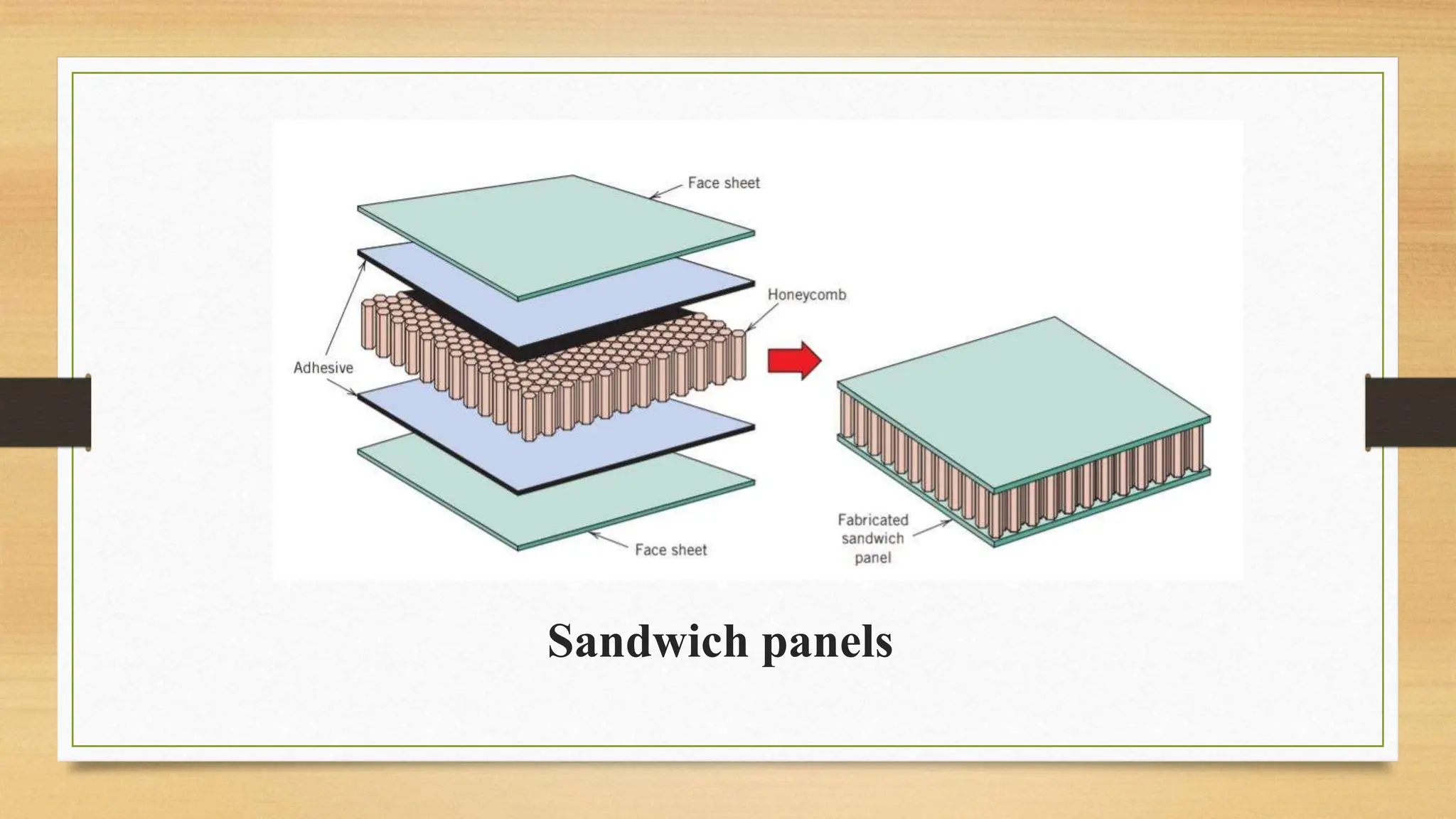

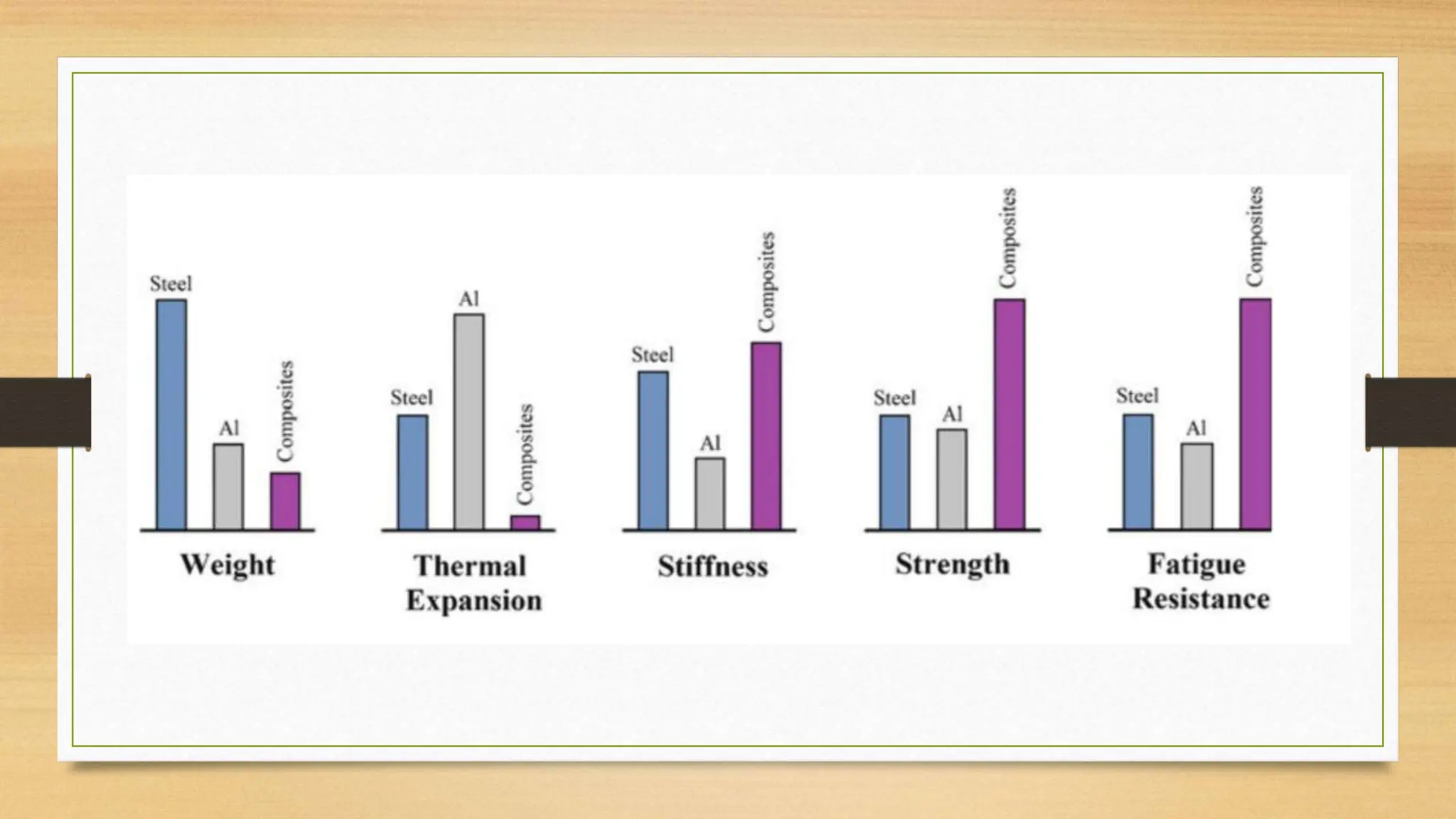

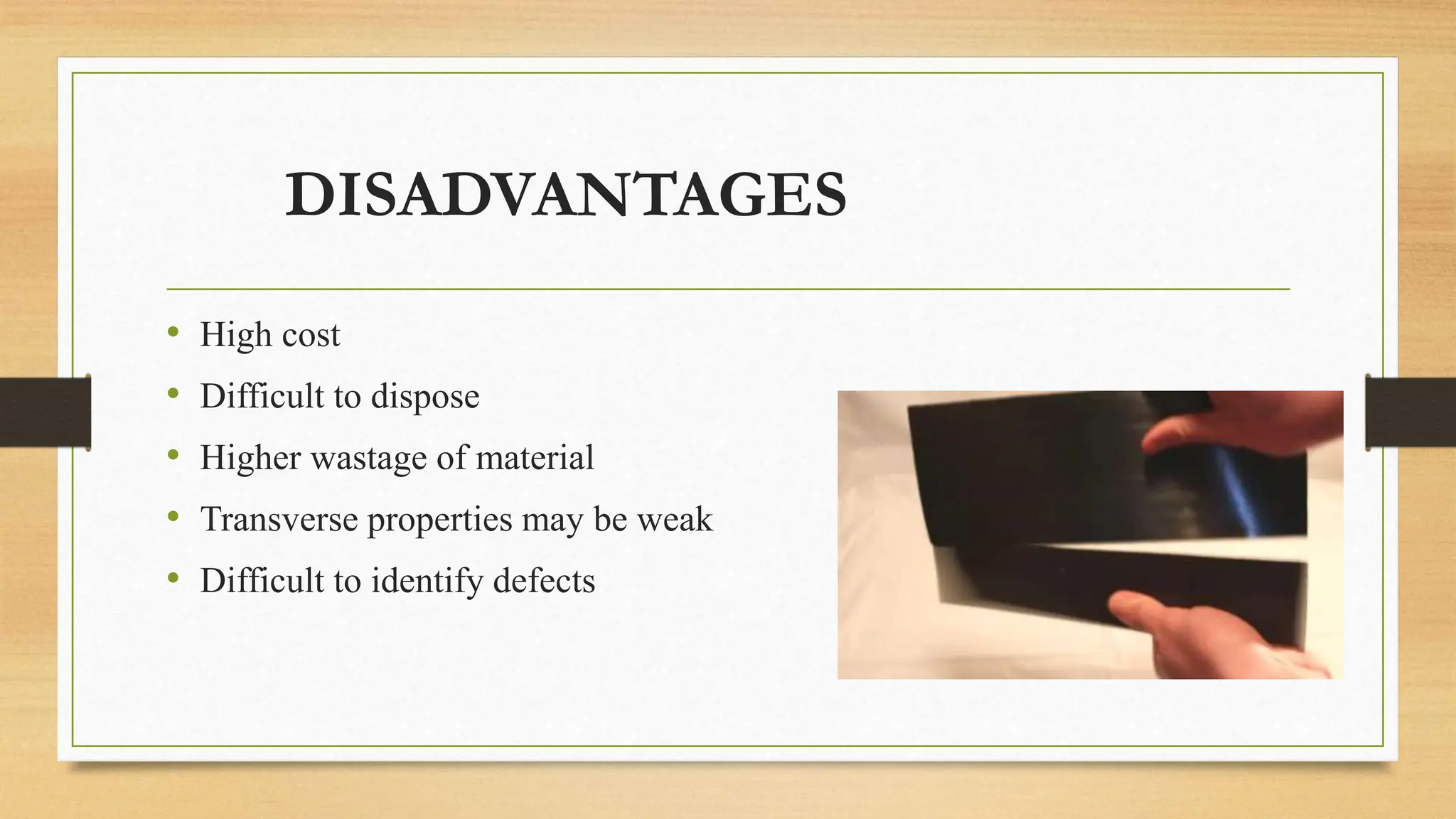

A composite material is produced by combining two or more materials with different physical or chemical properties to create a new material with unique properties. A composite contains a matrix that binds reinforcing materials like fibers, particles, or laminates. Common matrices include polymers, metals, and ceramics, while reinforcements include fibers, particles, and sandwich panels. Composites have advantages over alloys like high strength to weight ratio and design flexibility, but also disadvantages such as high cost and difficulty identifying defects. Major applications of composites include aerospace, construction, sports equipment, and motorsports.