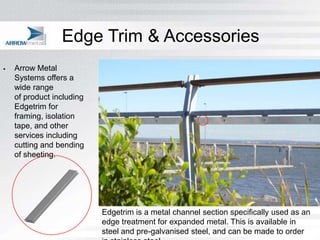

Arrow Metal Systems aims to provide outstanding service and high quality perforated metal, welded wire mesh, and other products. It has a highly experienced team and state-of-the-art manufacturing facilities. Arrow offers a wide range of standard and custom products across various categories like perforated metal, expanded metal, welded wire mesh, and more. It is focused on meeting customer needs through quality products and service.