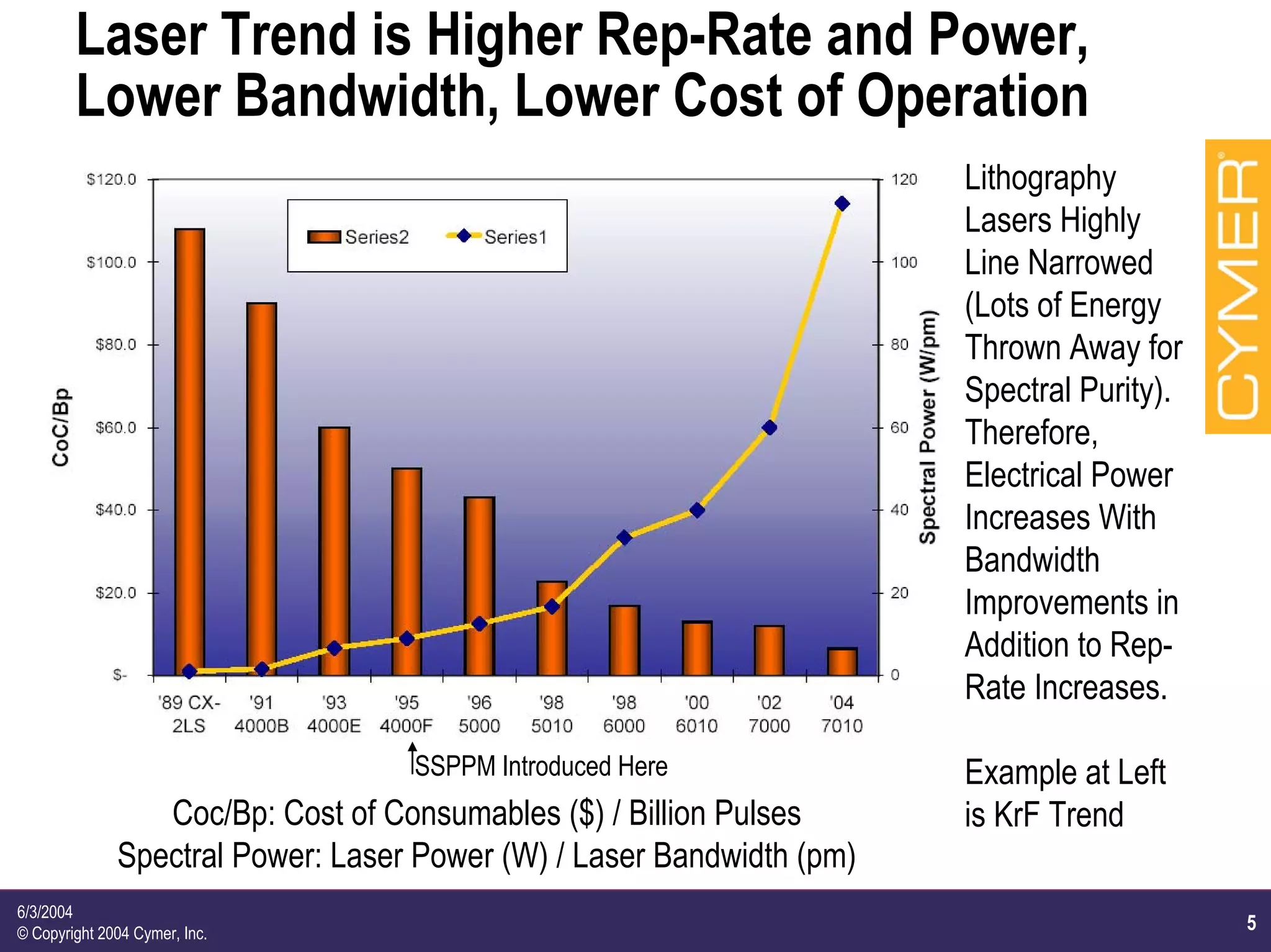

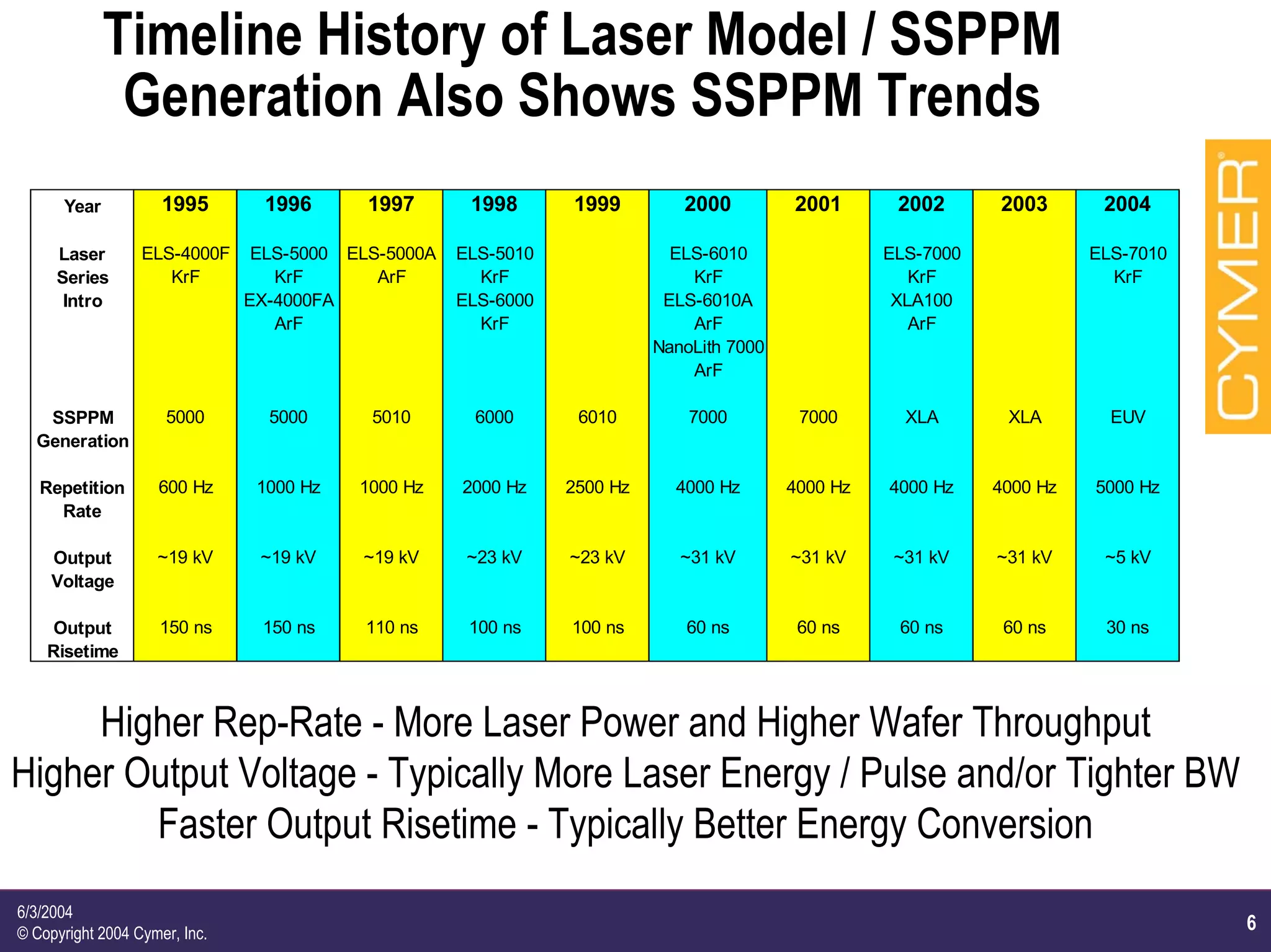

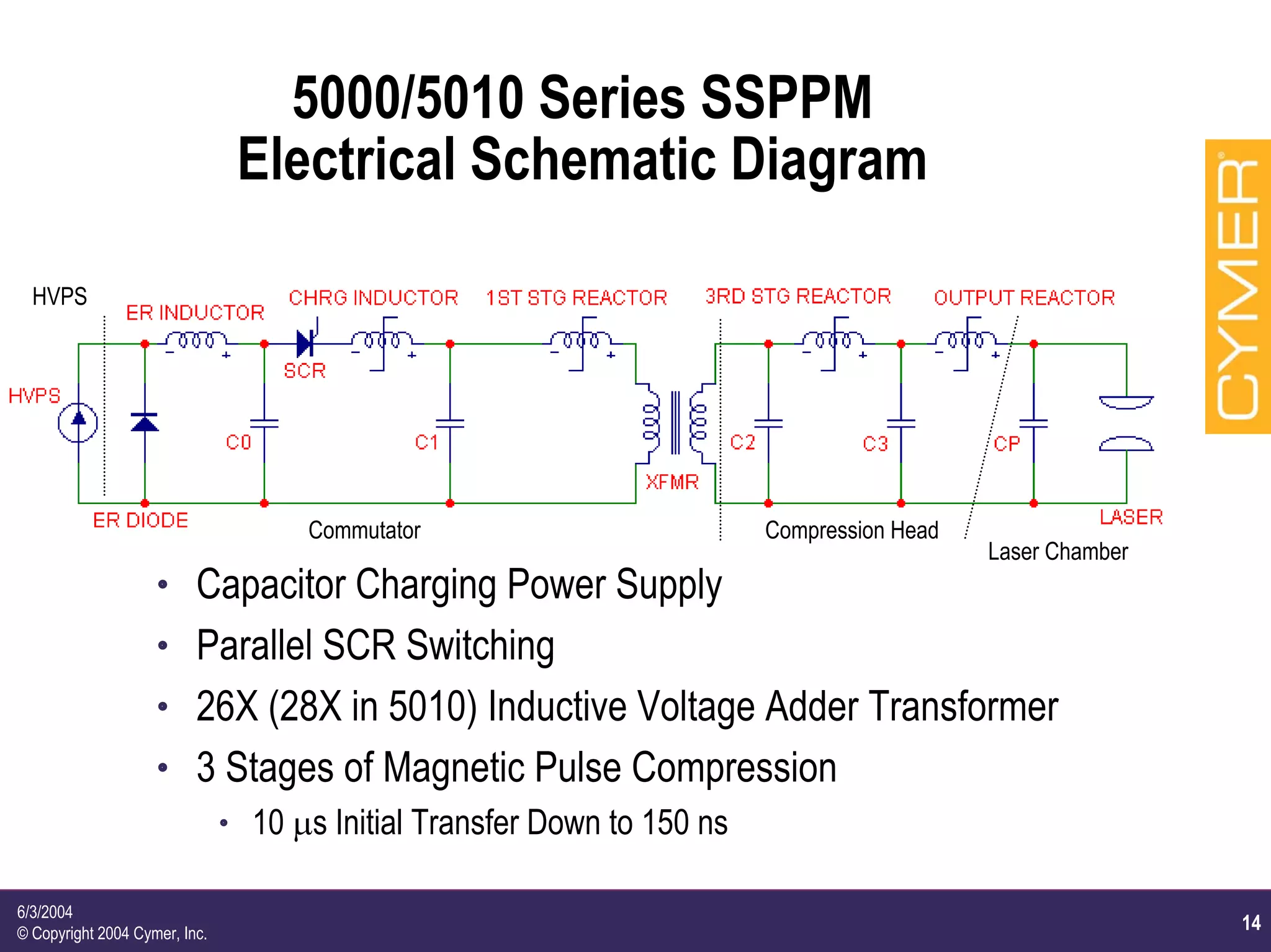

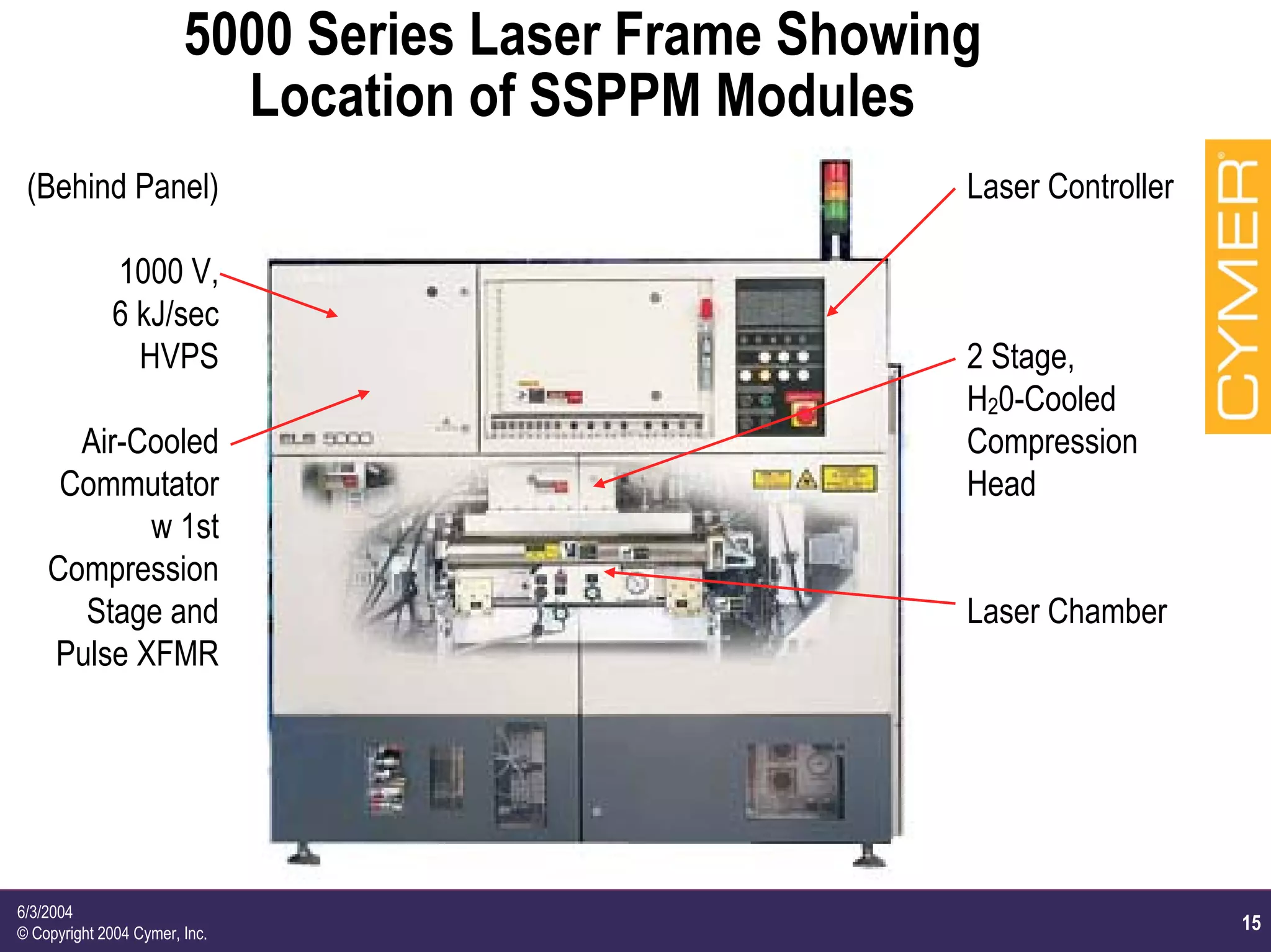

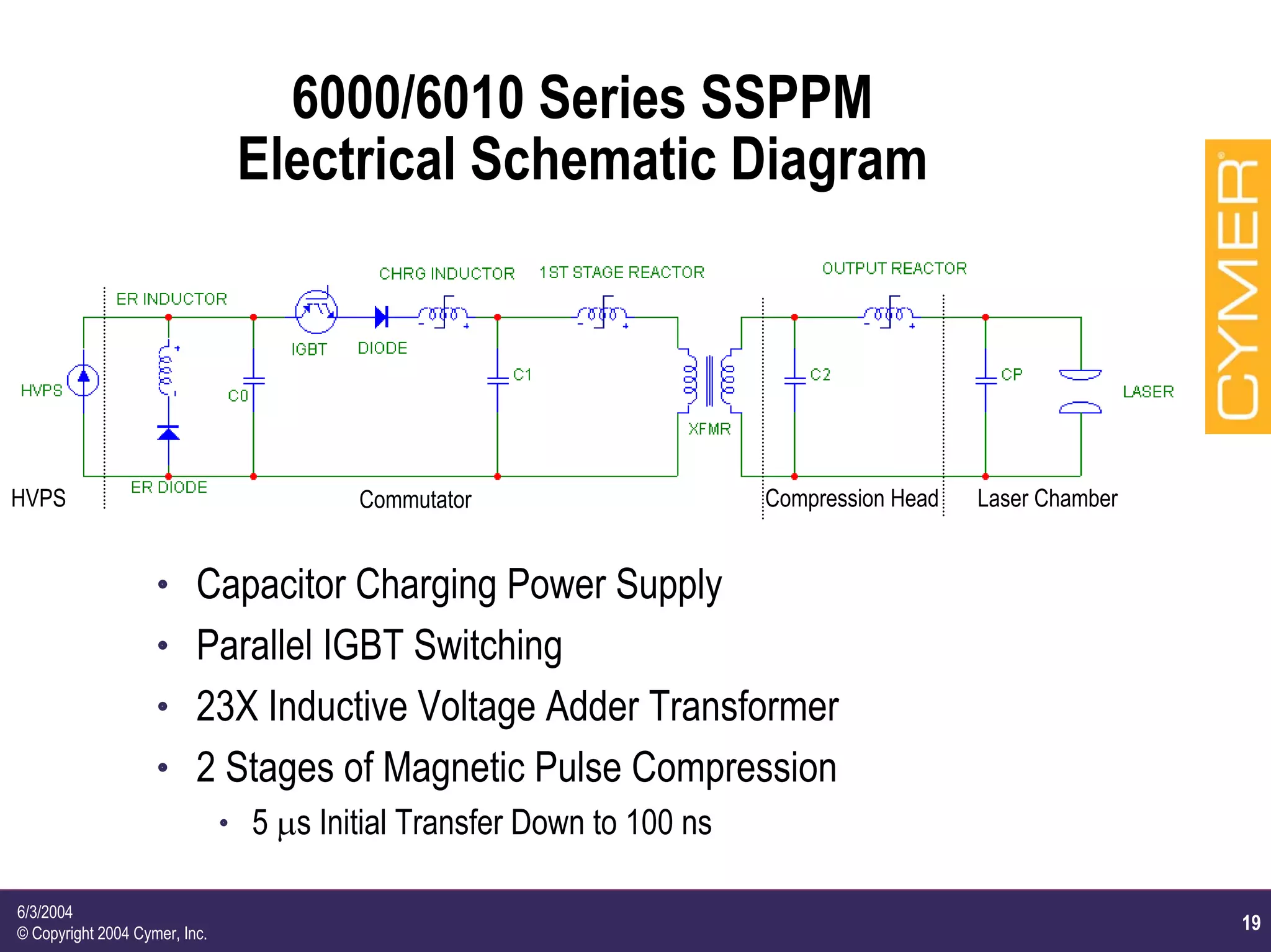

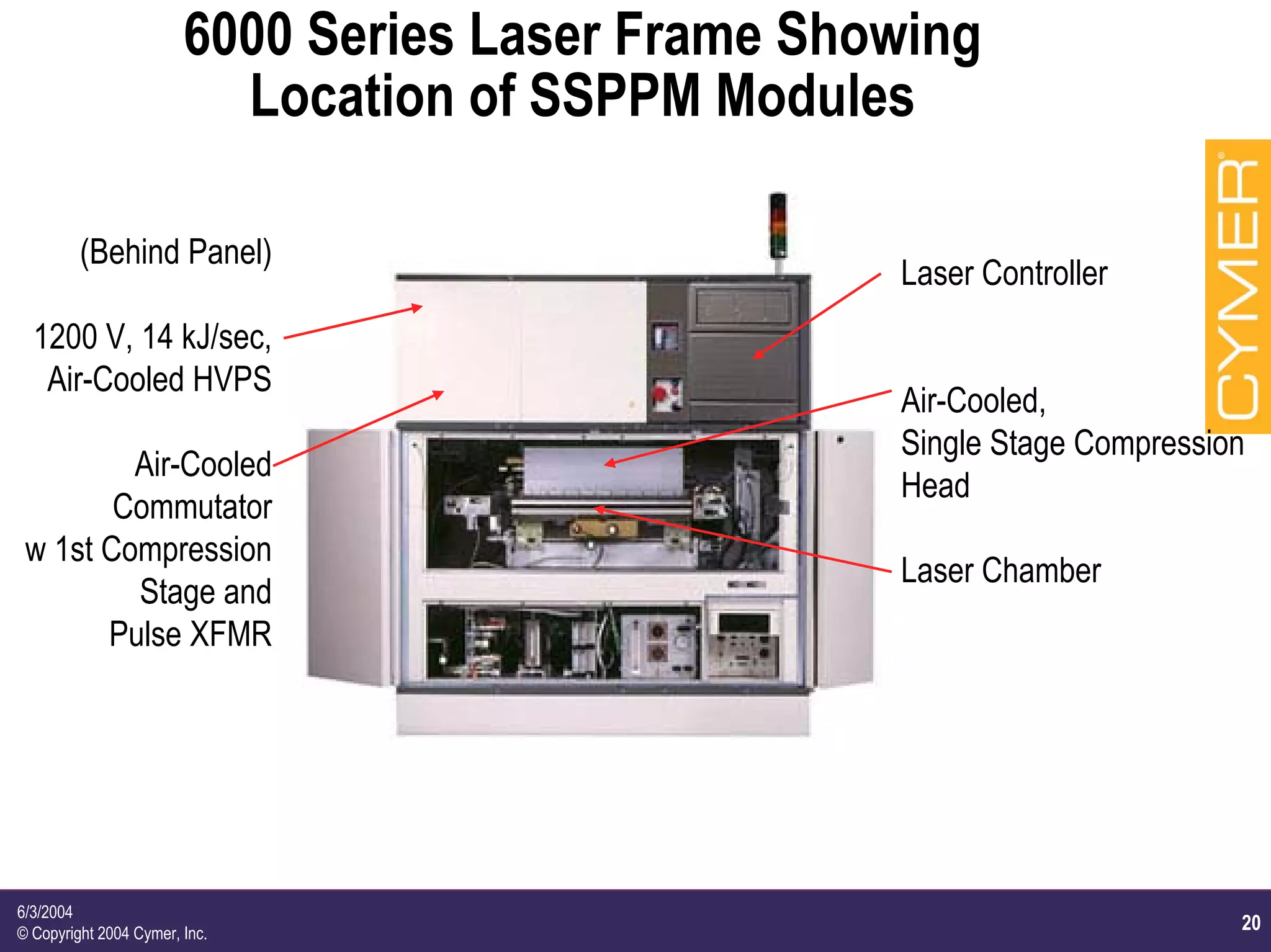

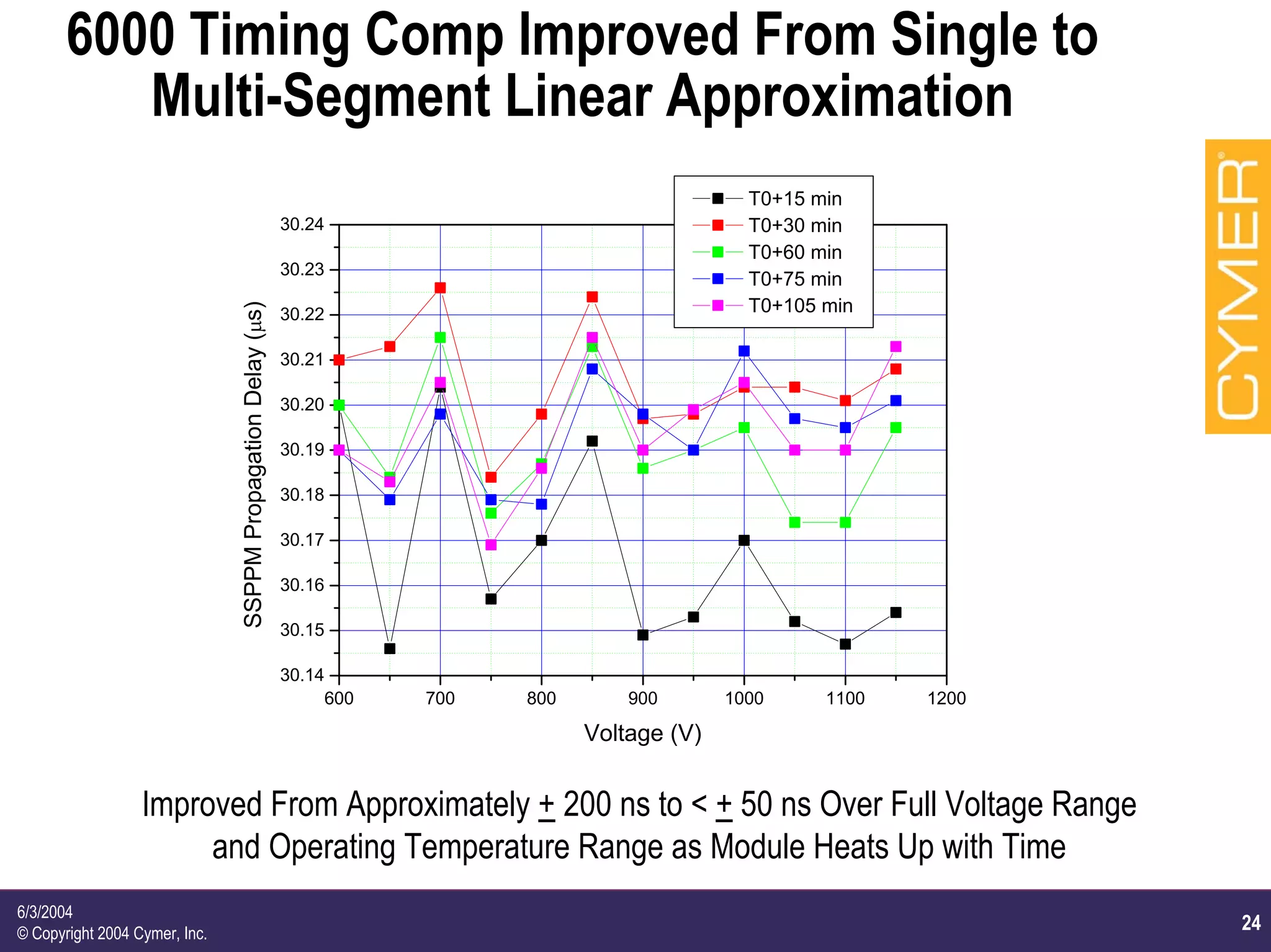

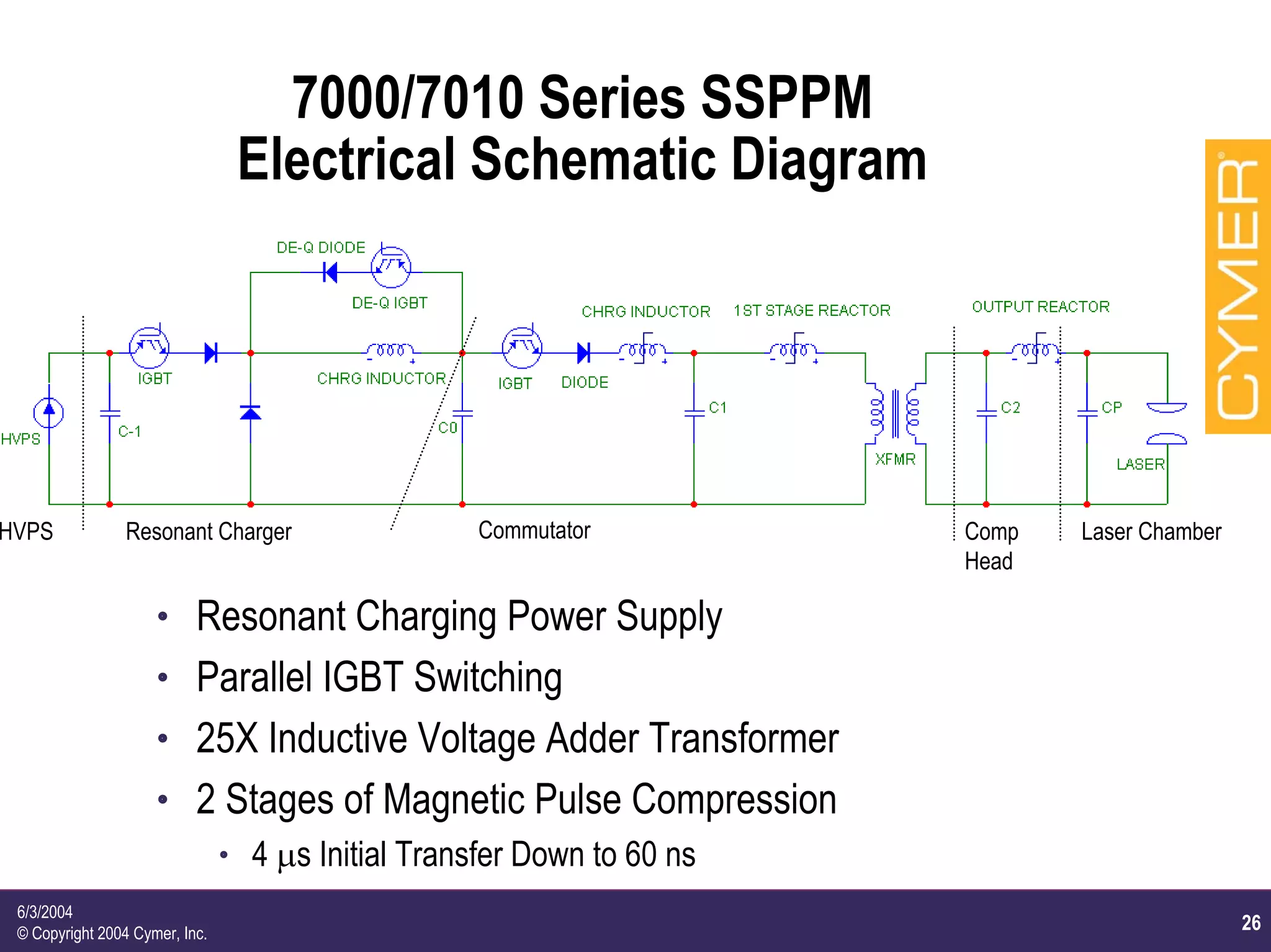

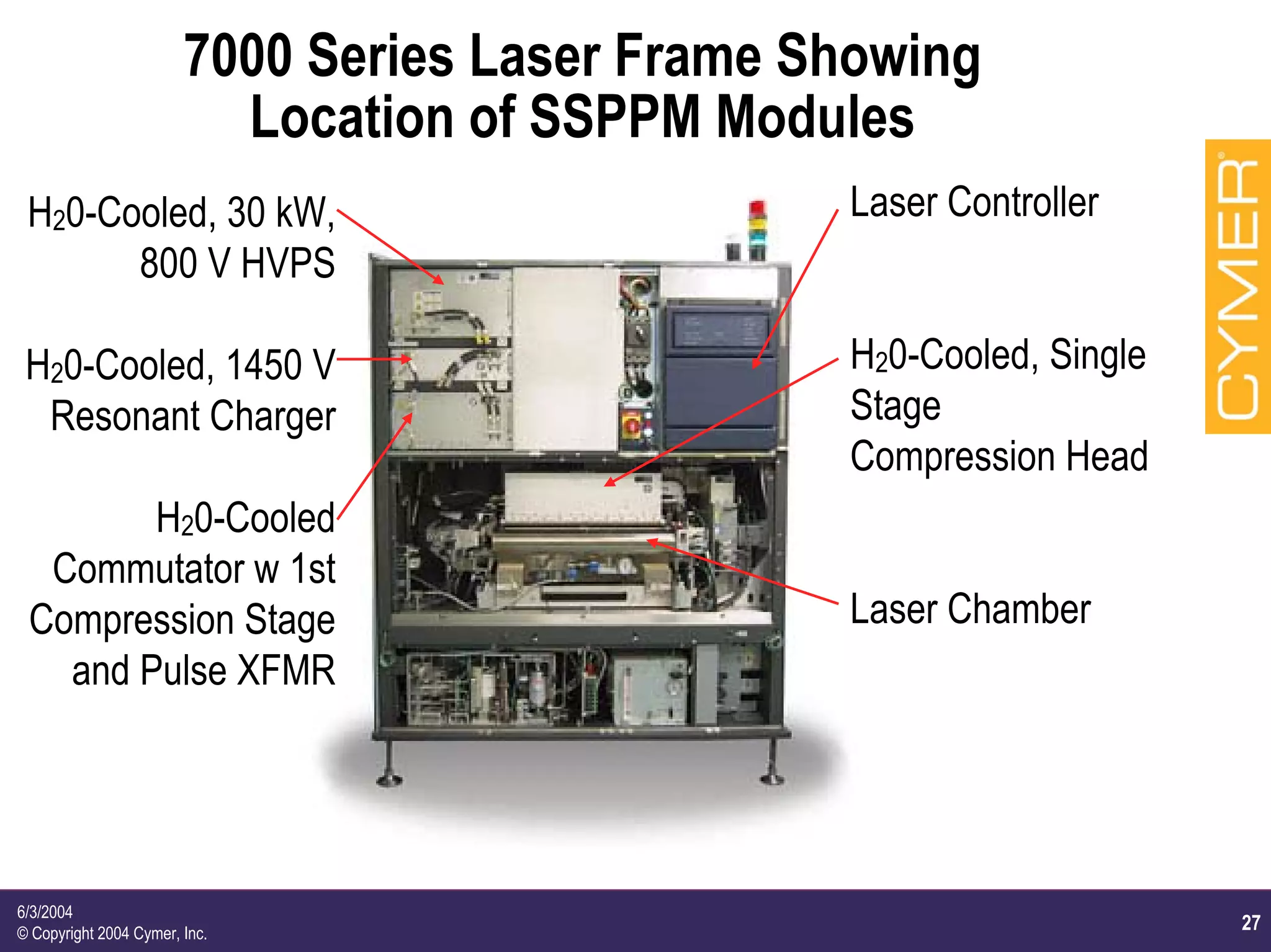

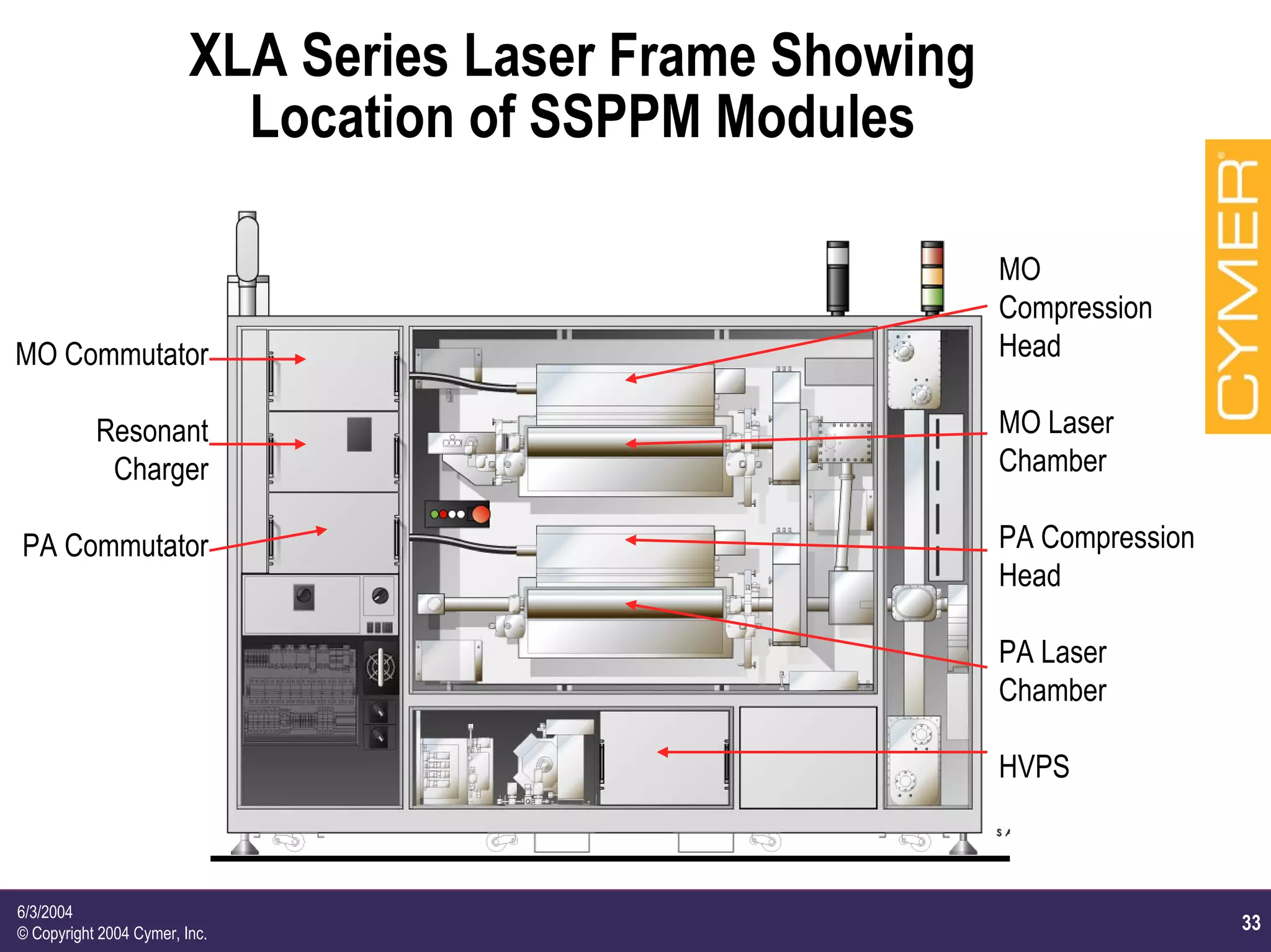

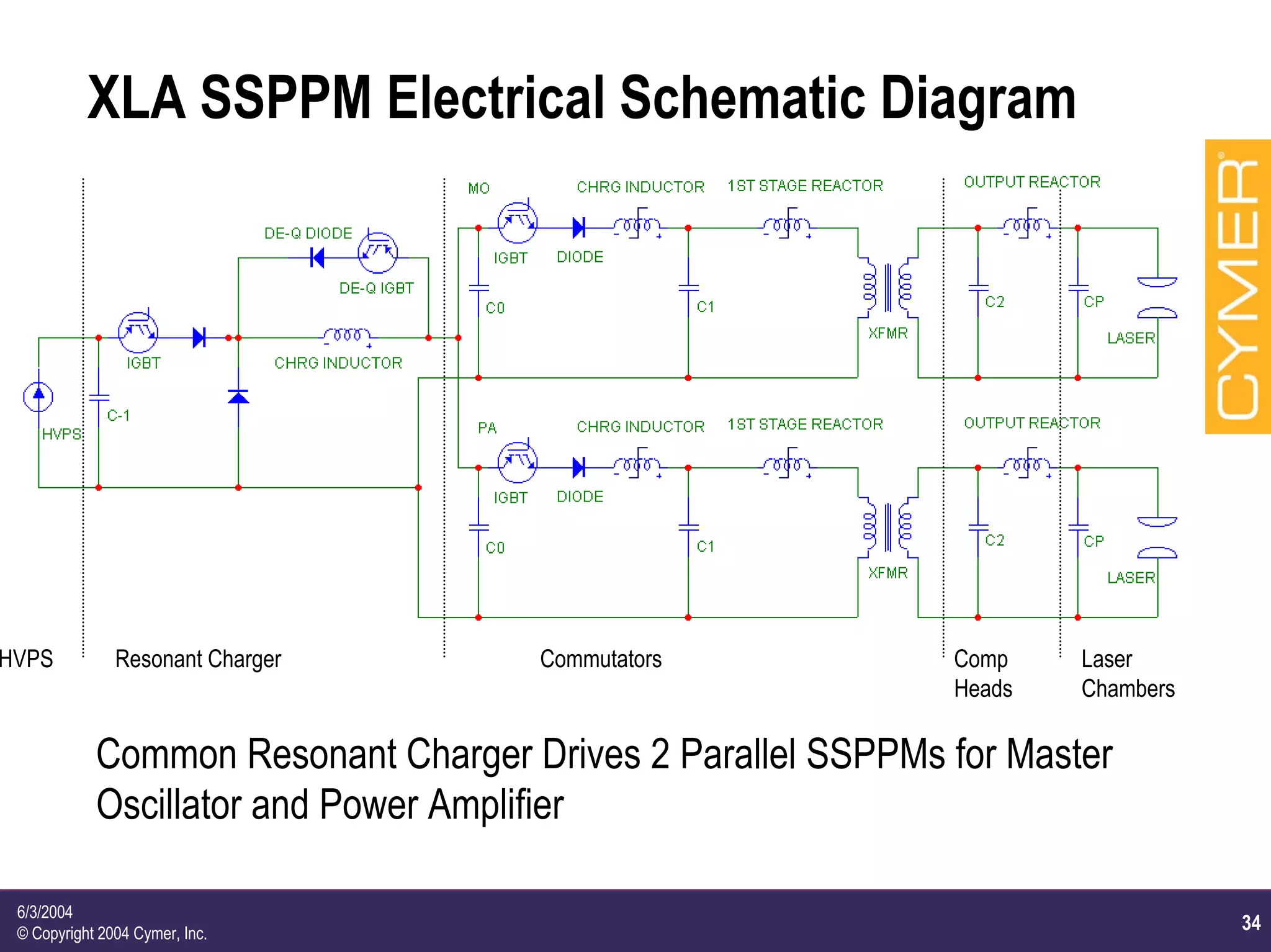

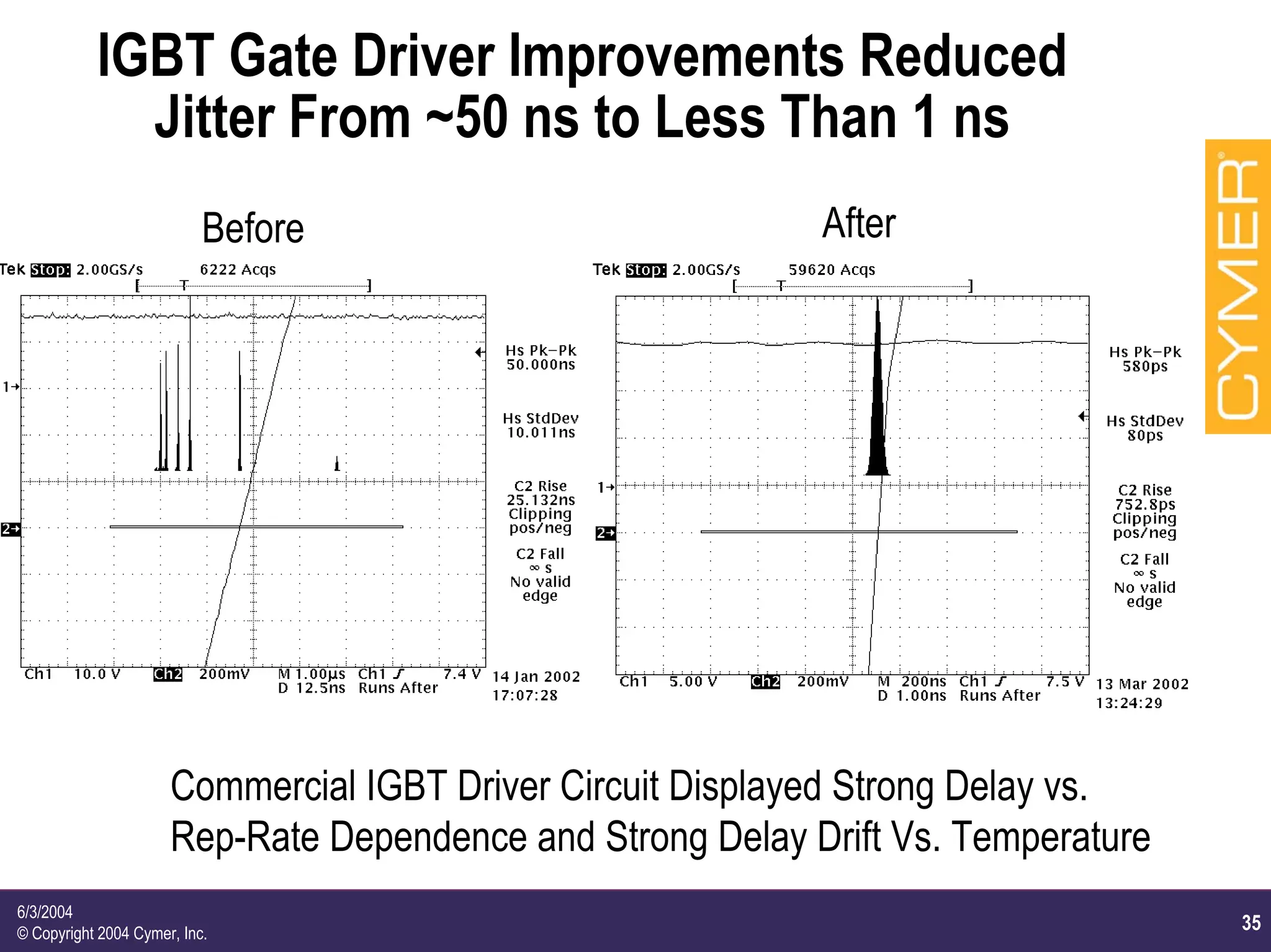

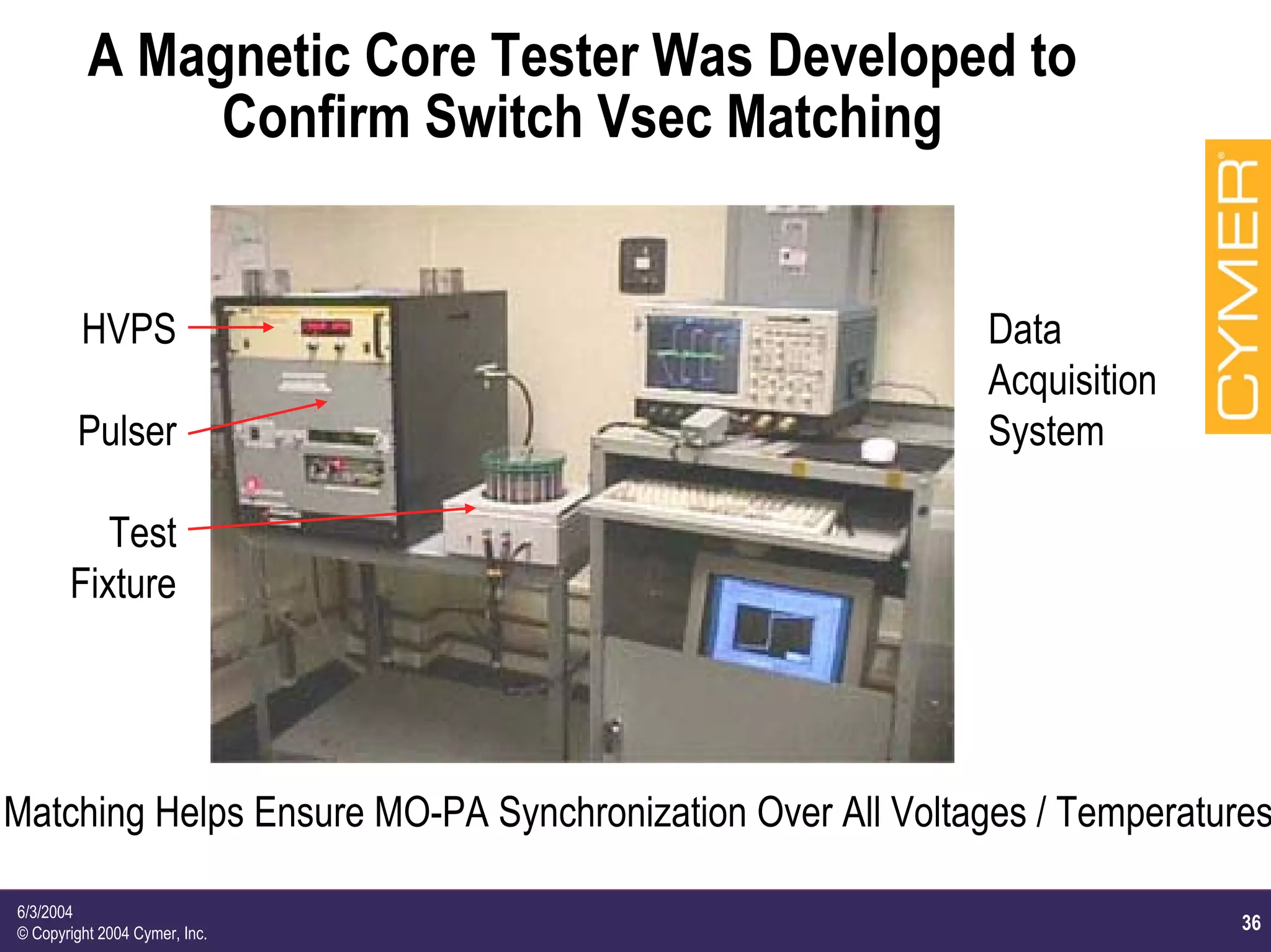

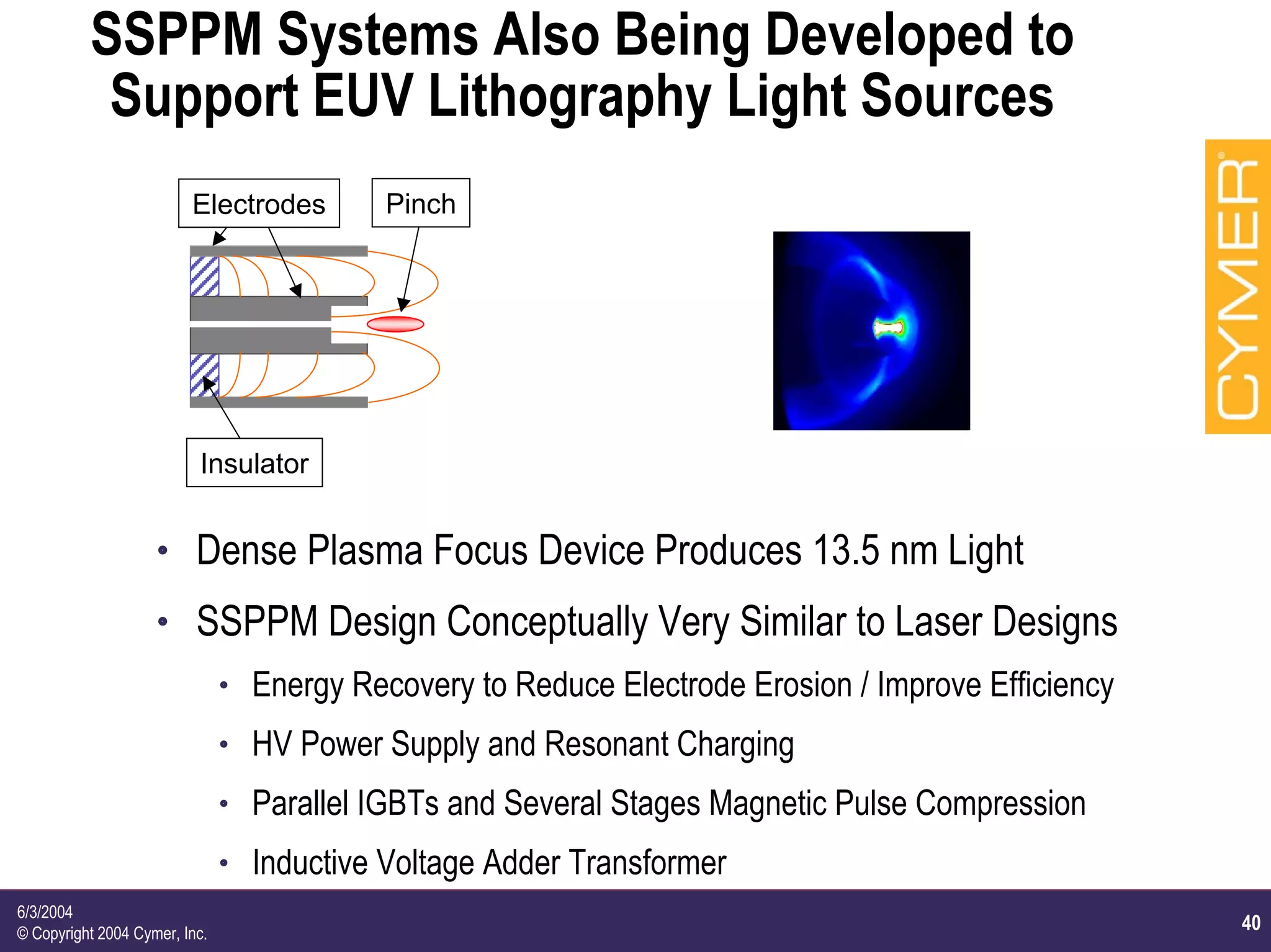

The document provides an overview of Cymer Inc.'s development of solid state pulsed power modules (SSPPMs) over the past decade for use in their excimer lasers for semiconductor lithography. Key points discussed include: the transition in the early 1990s from thyratron-based pulse power to SSPPM technology; requirements for high reliability and lifetime to meet semiconductor fab needs; challenges in designing and manufacturing SSPPMs for high volume; and trends toward higher repetition rates, power, and tighter bandwidths over the generations of SSPPM and laser designs.