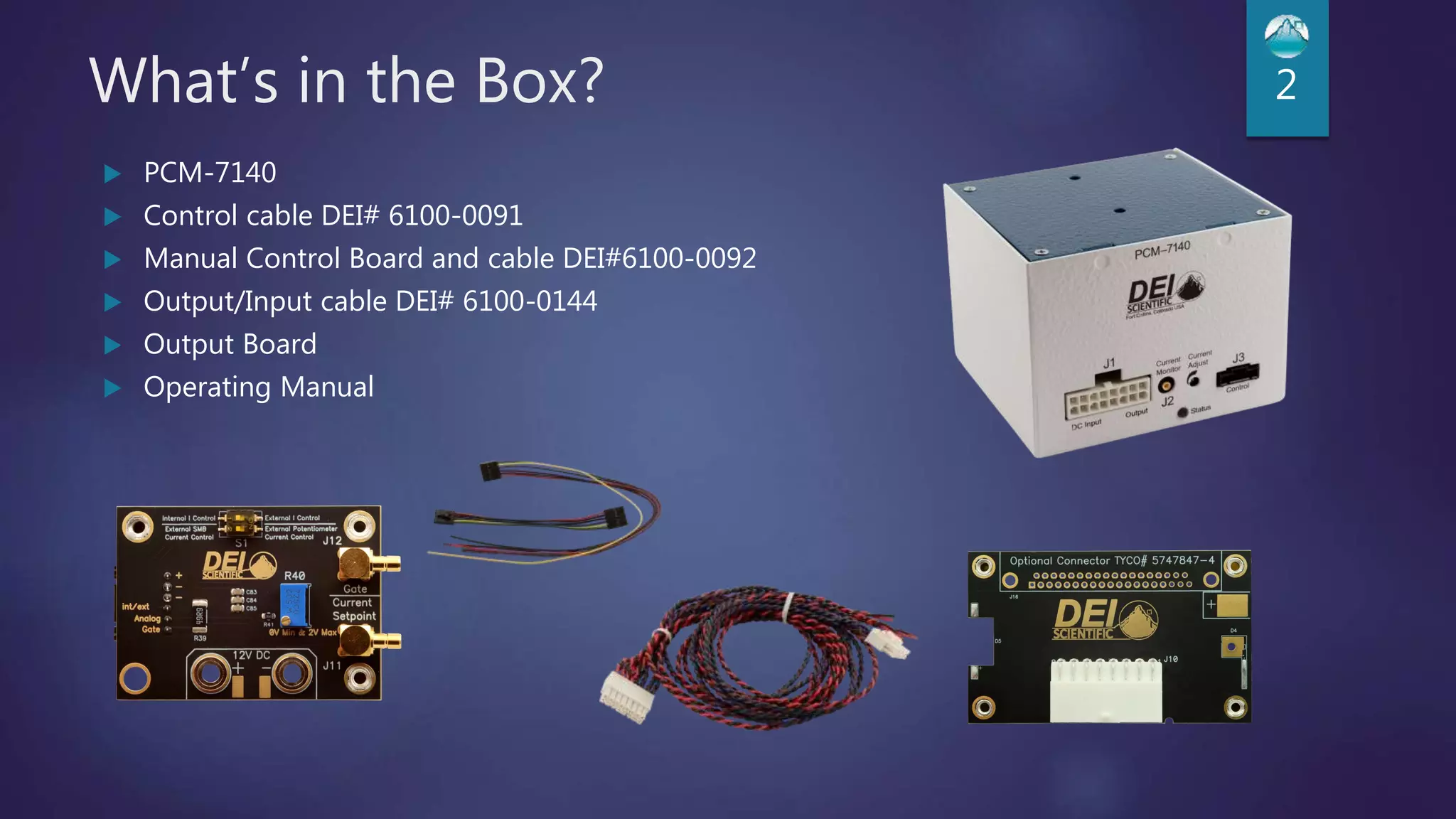

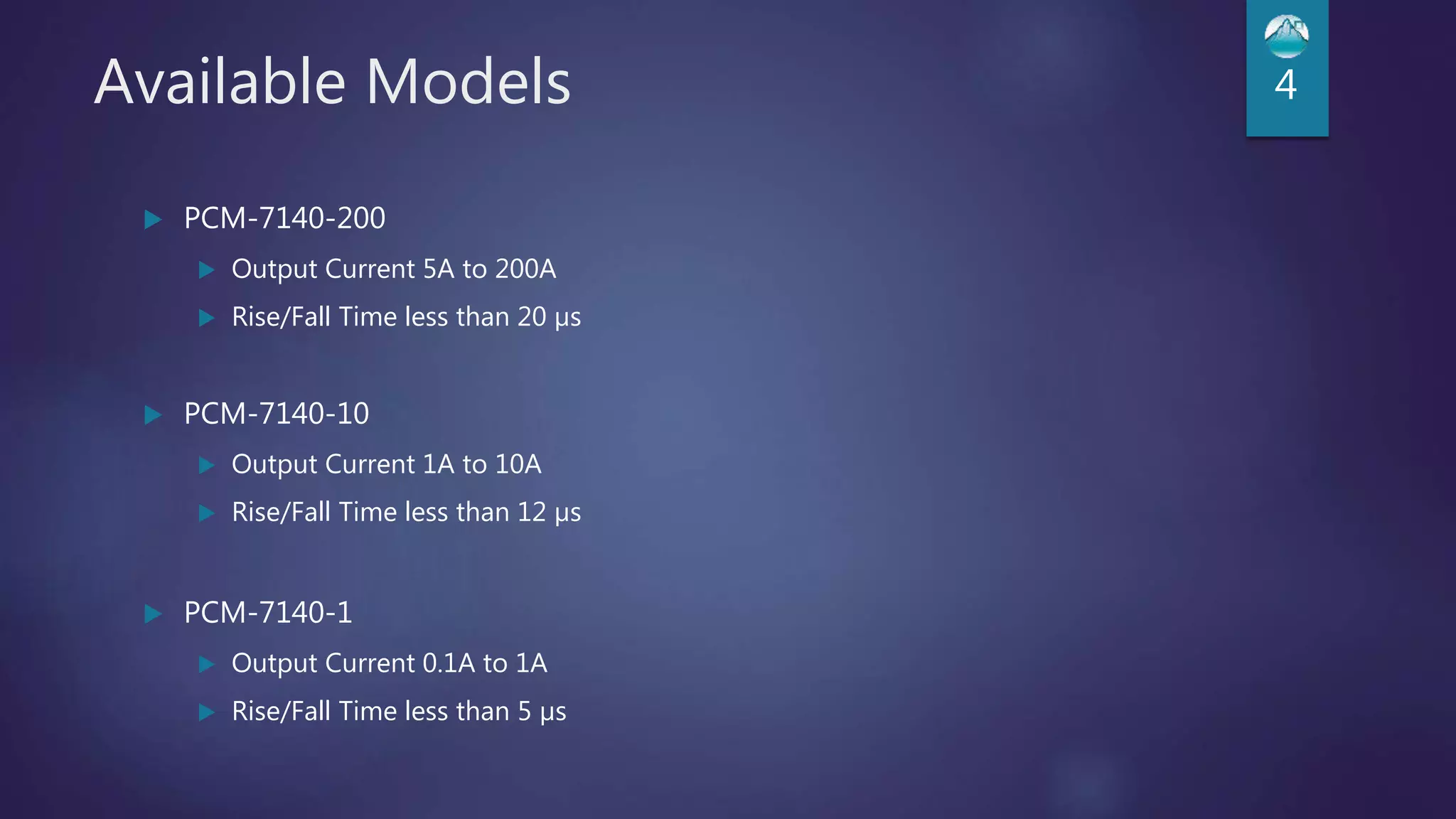

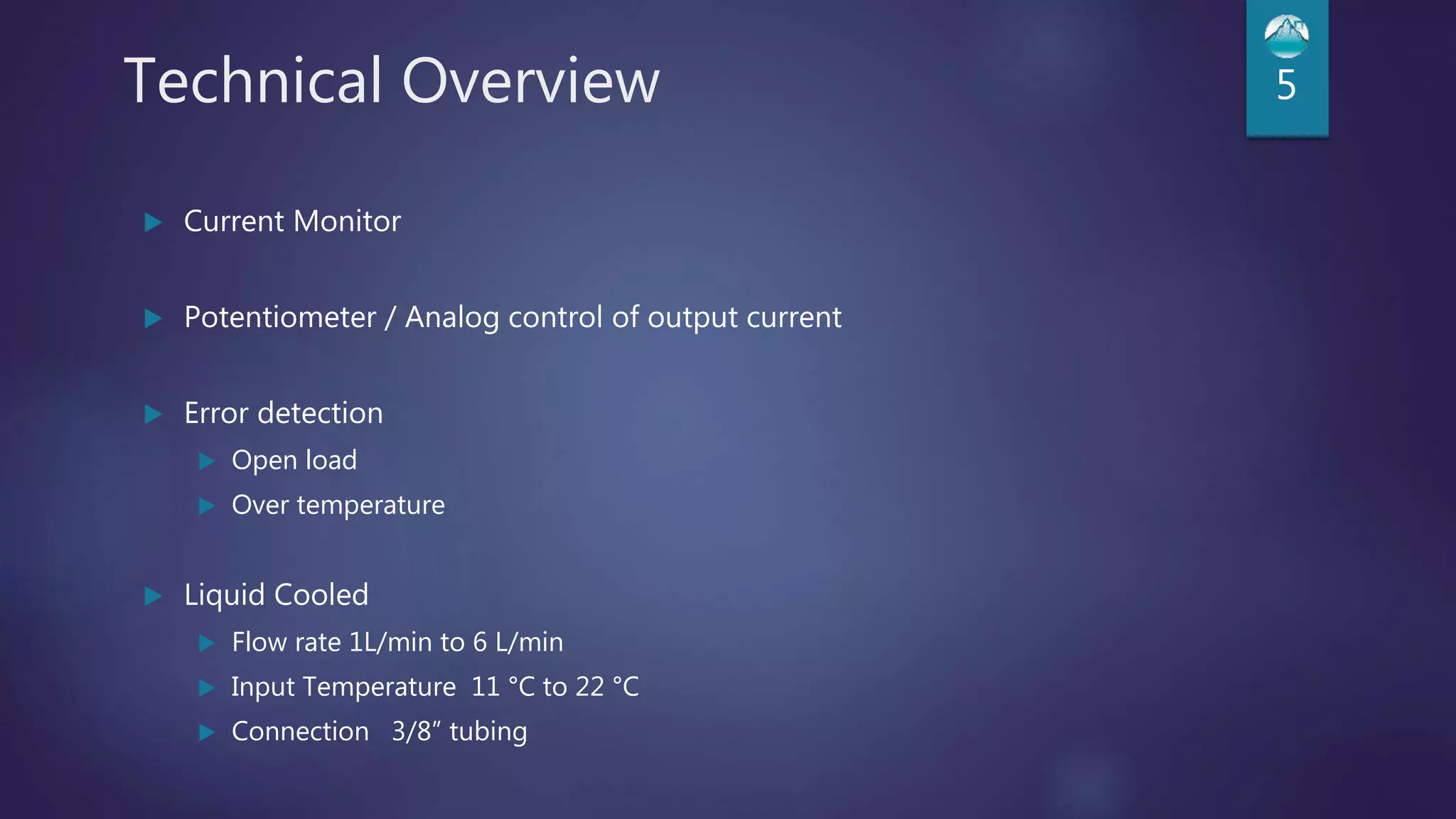

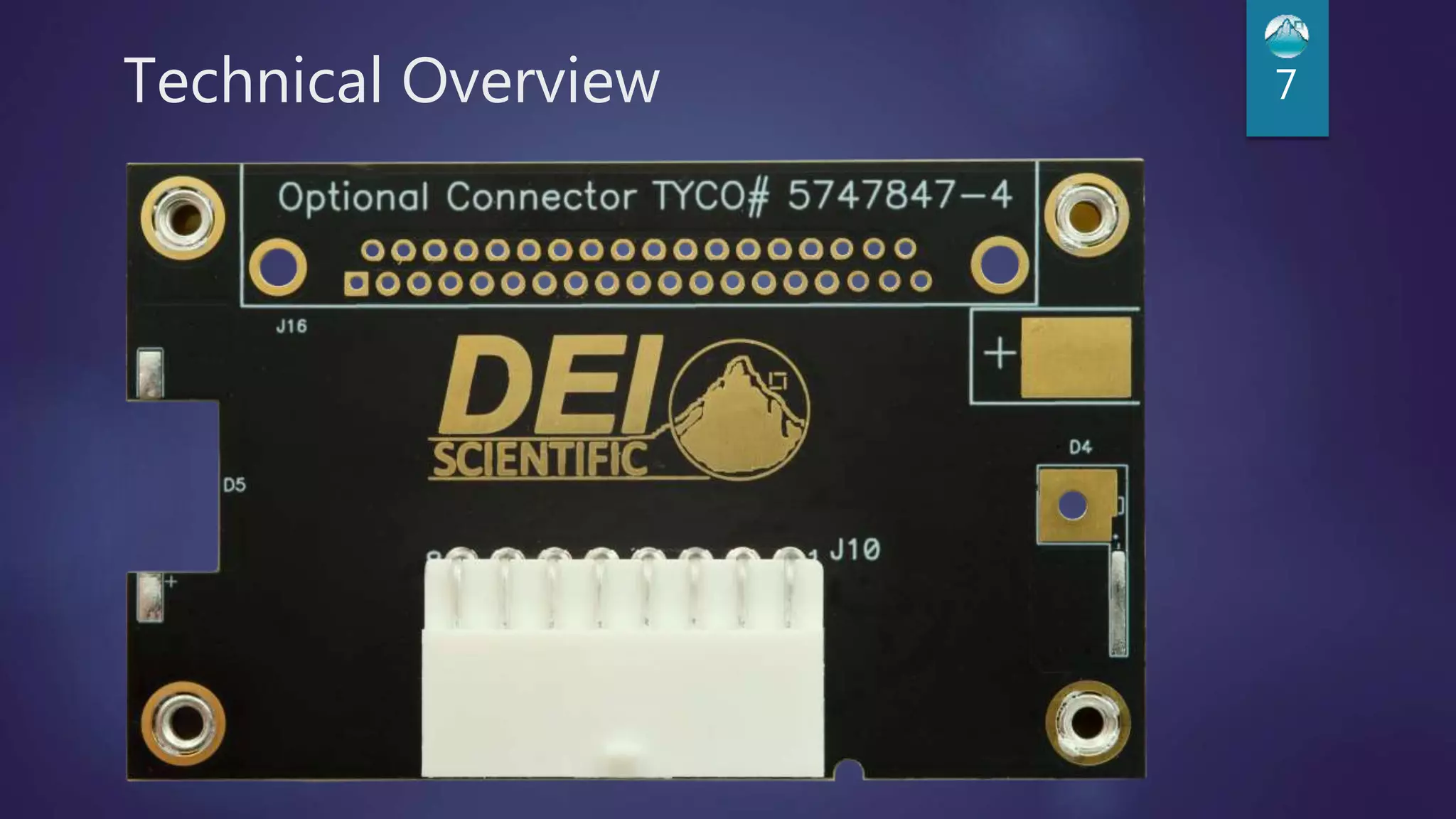

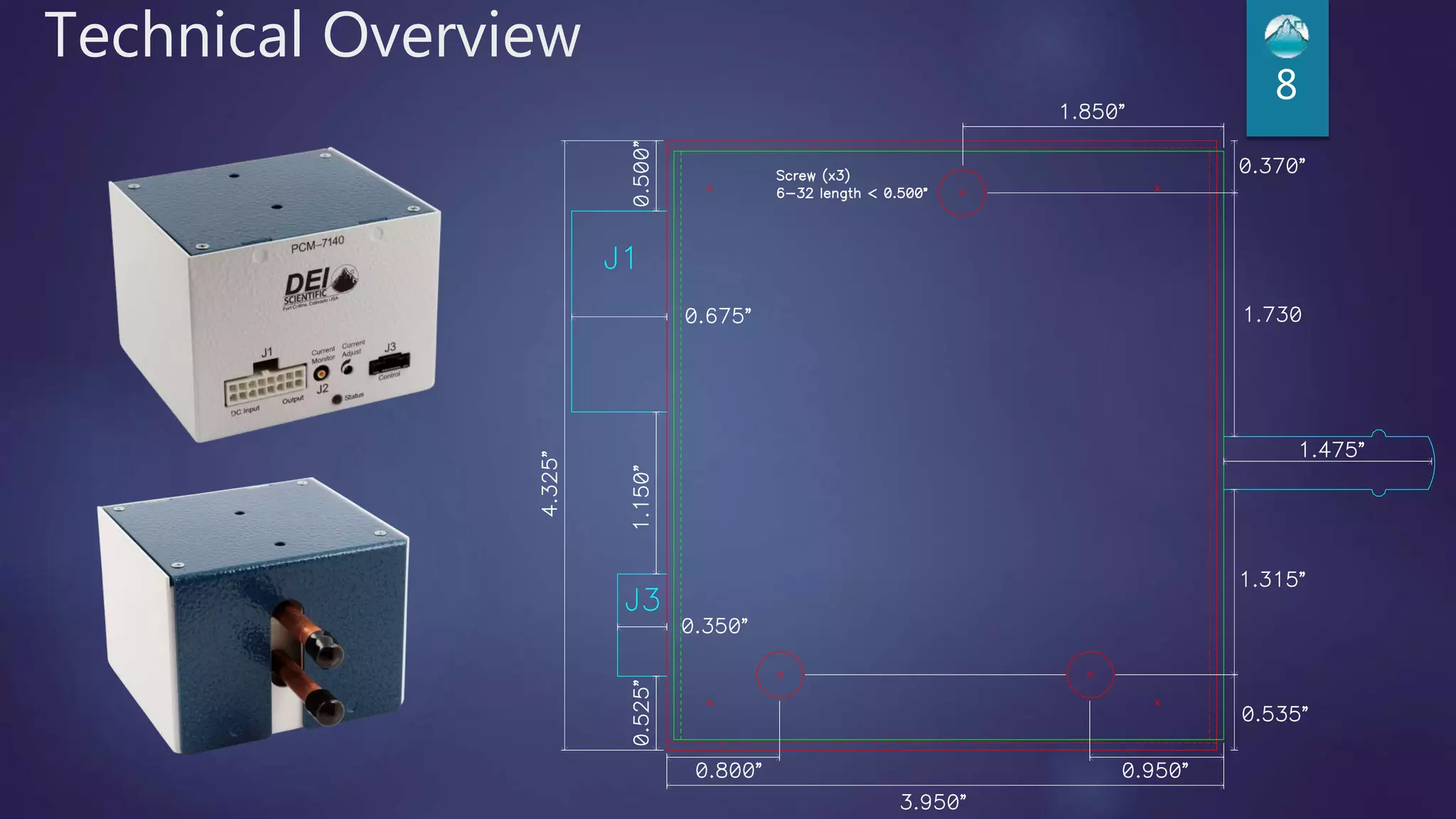

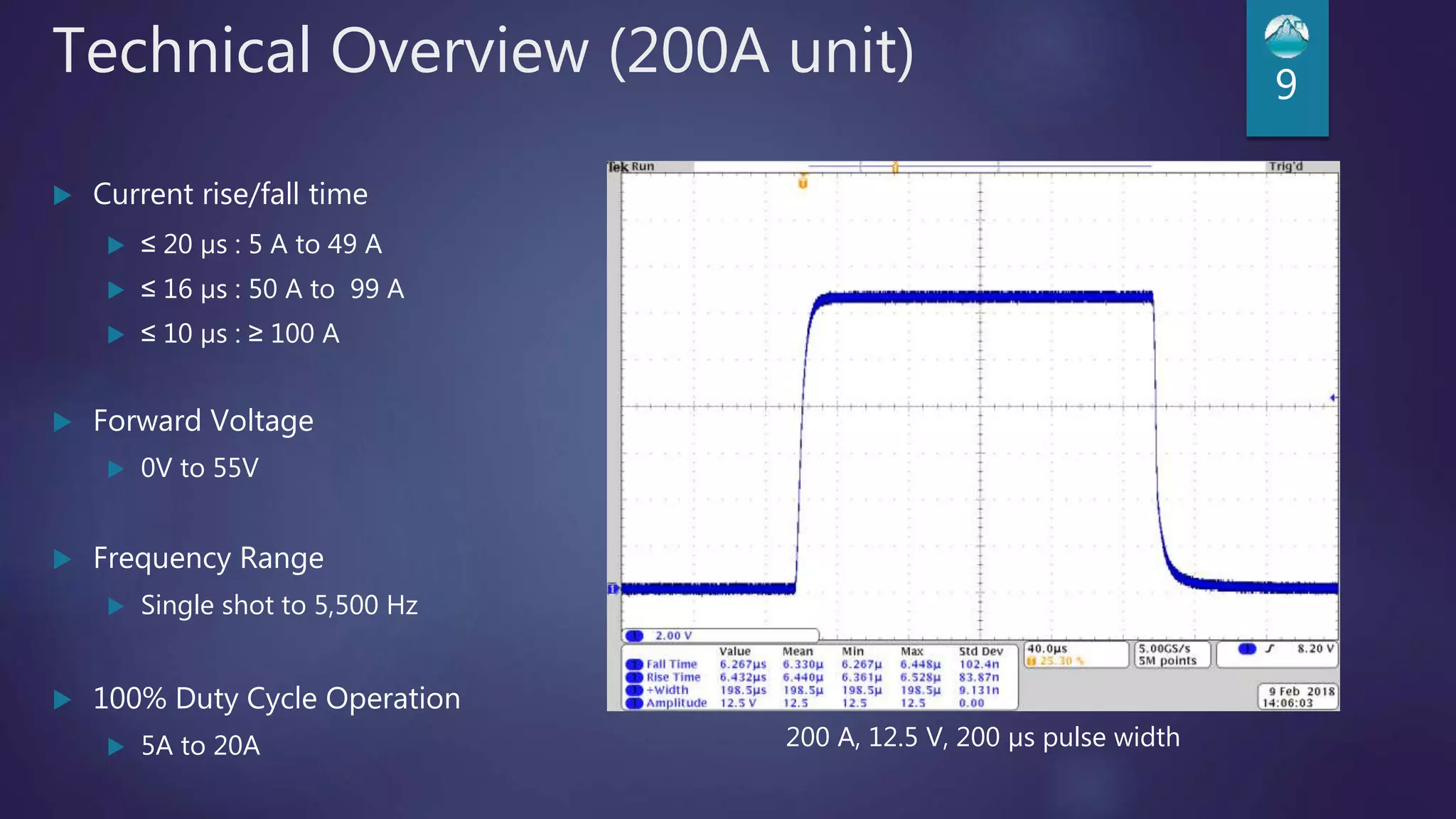

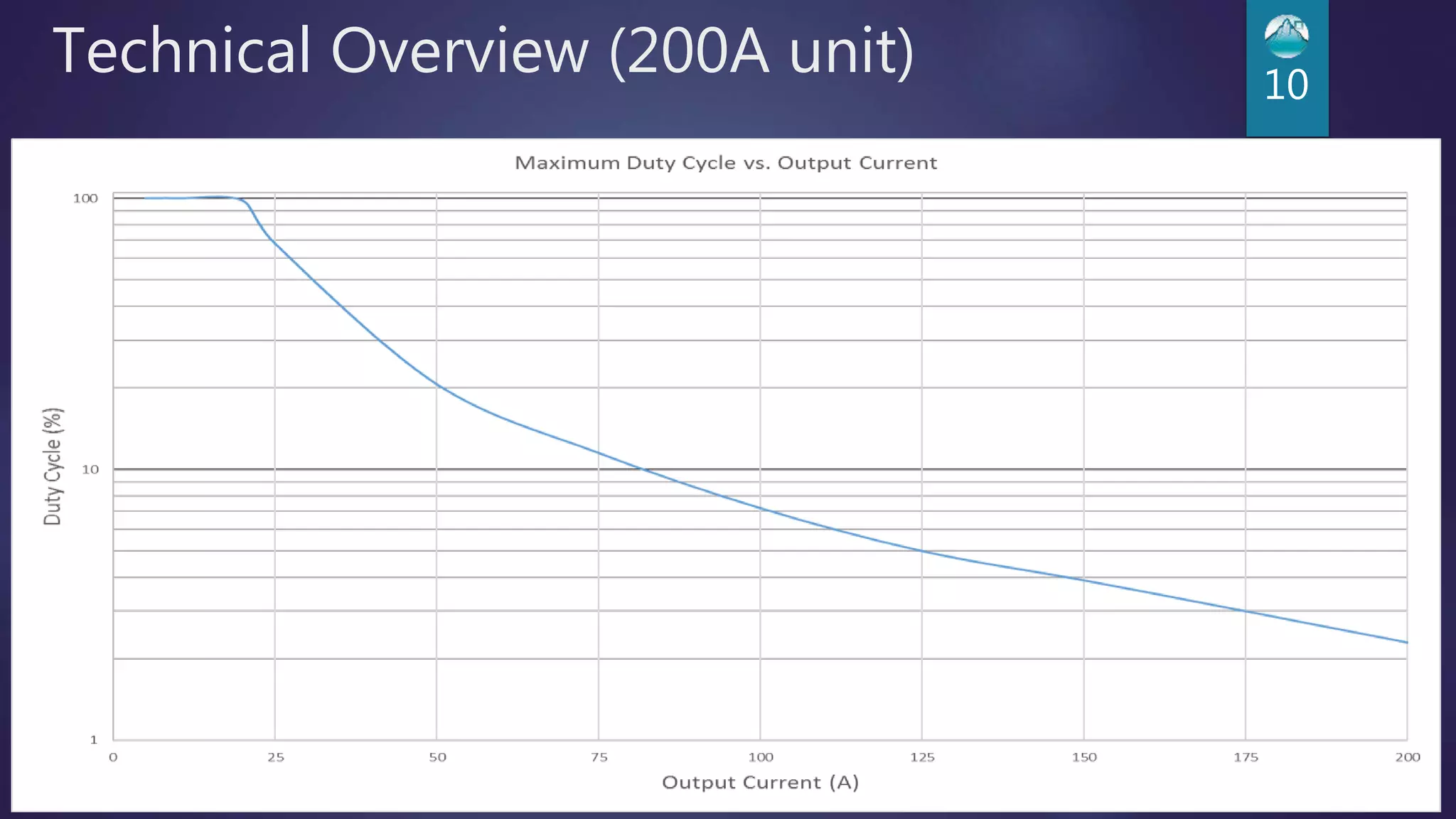

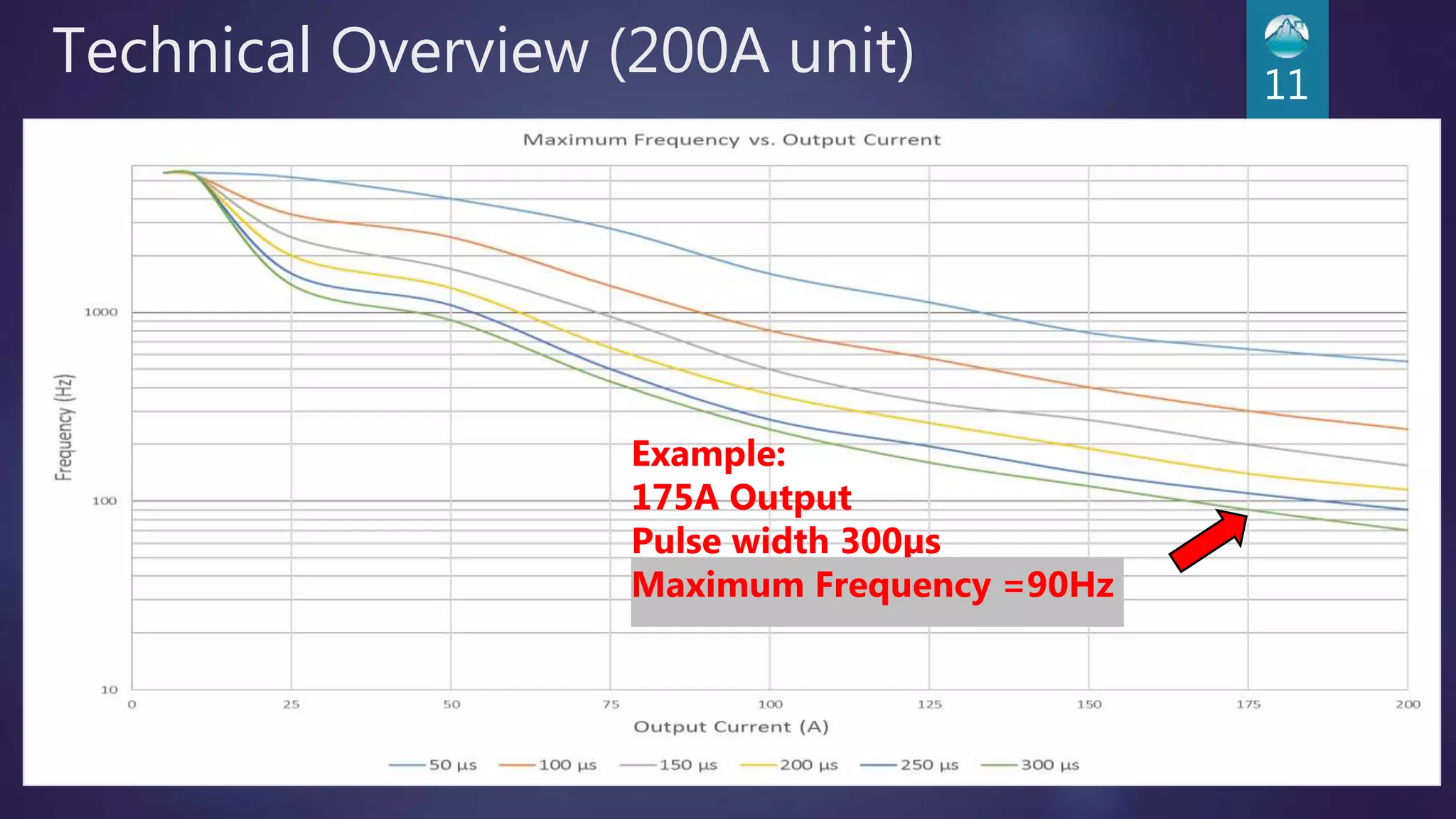

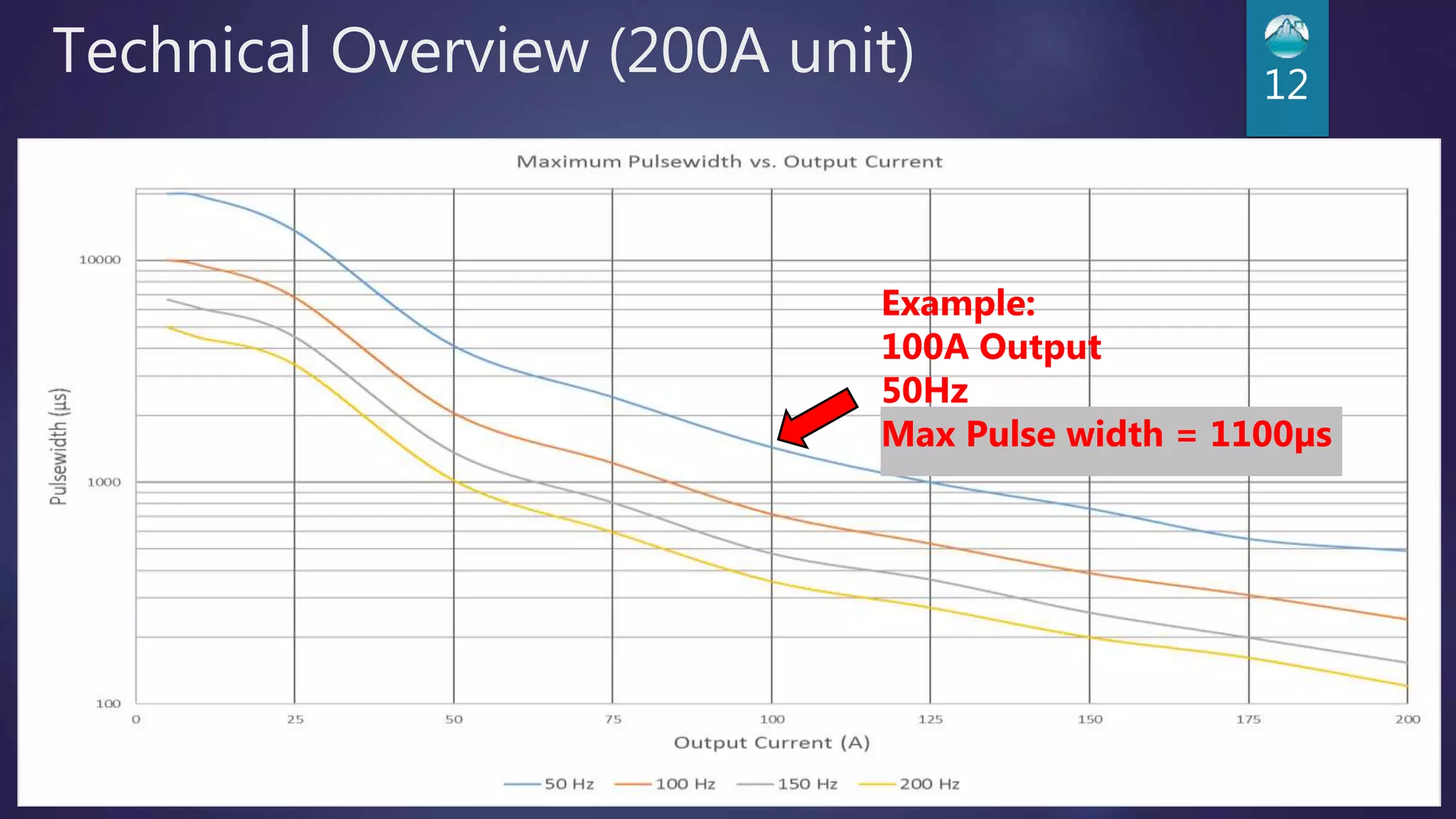

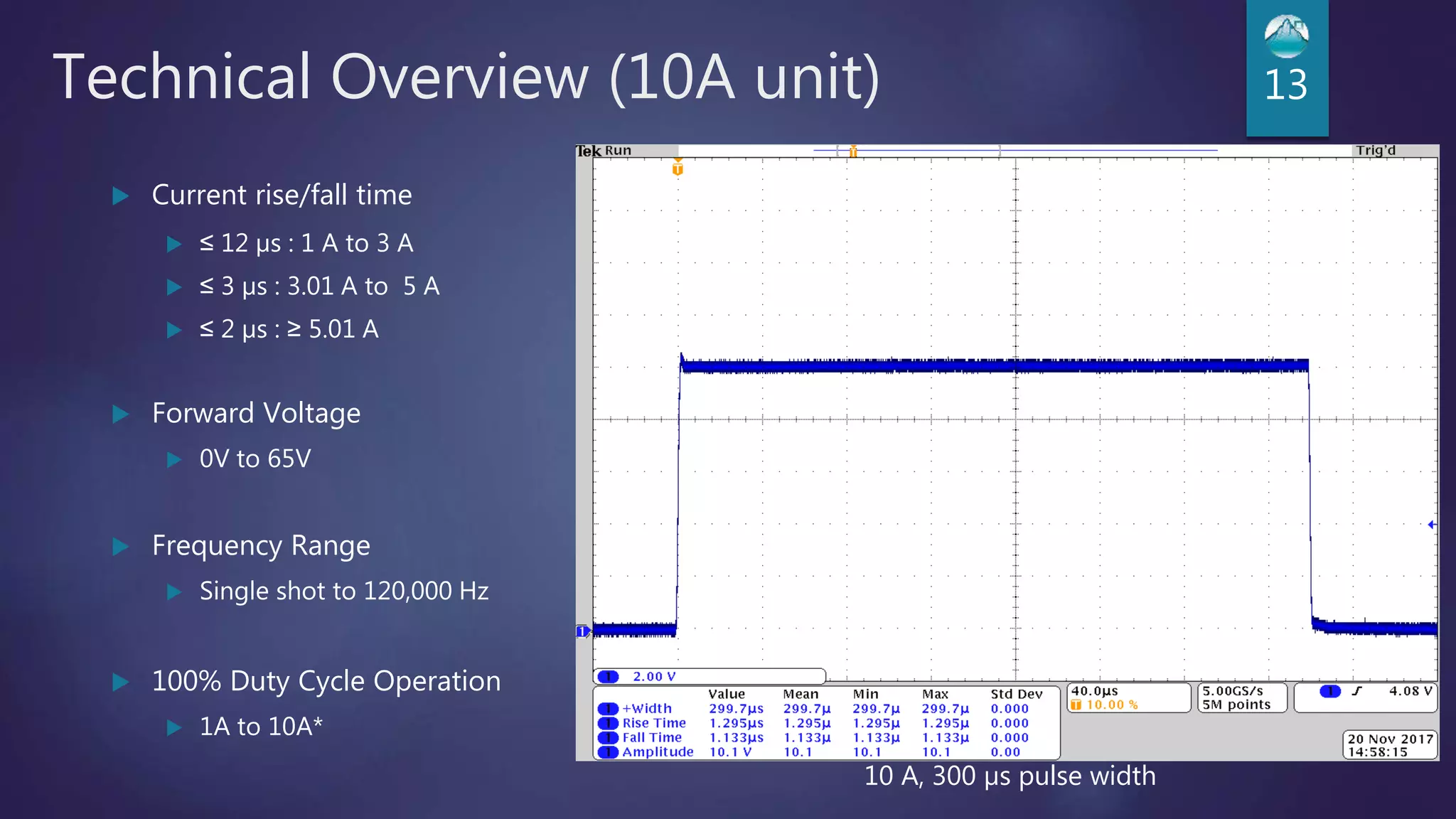

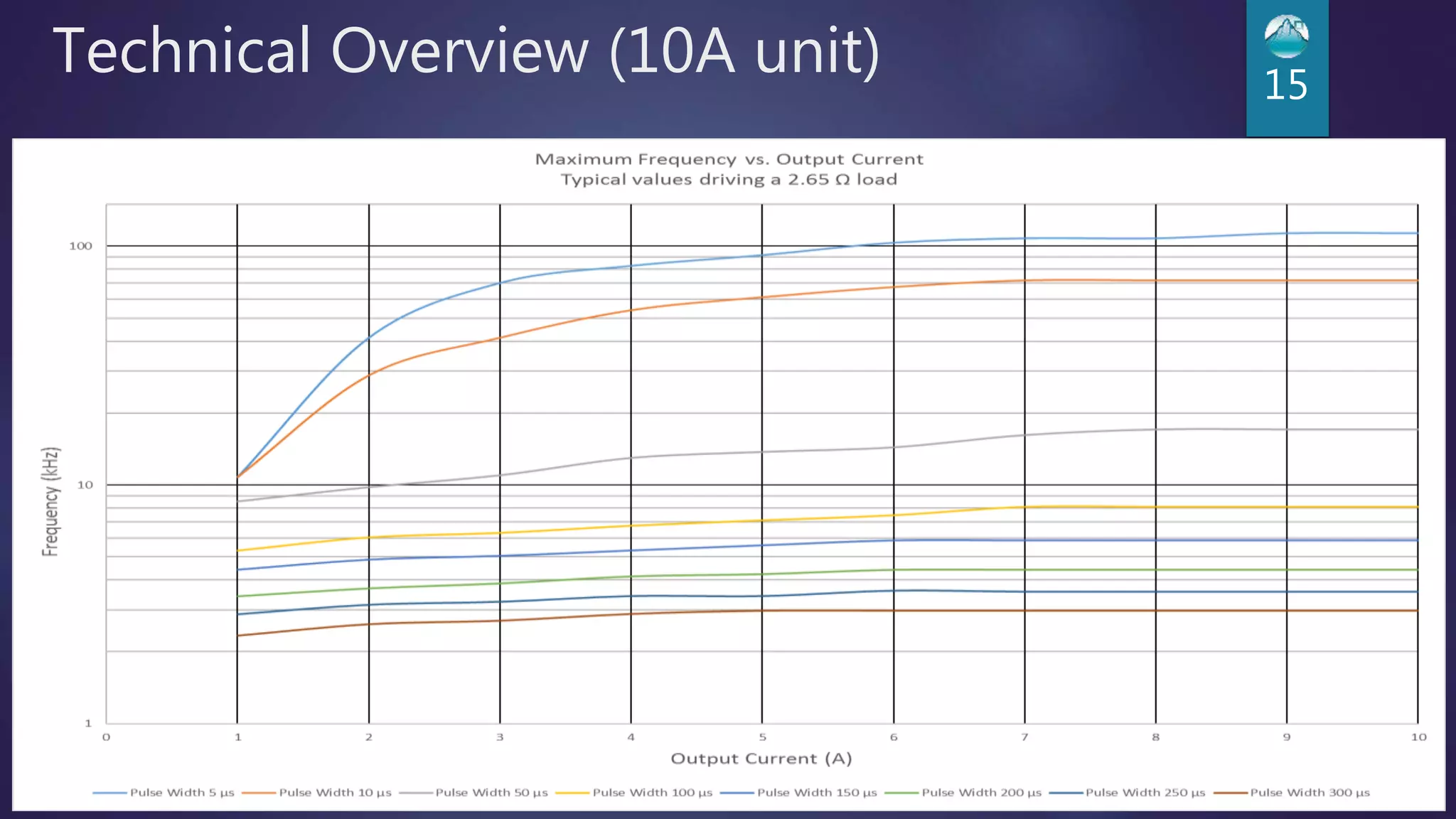

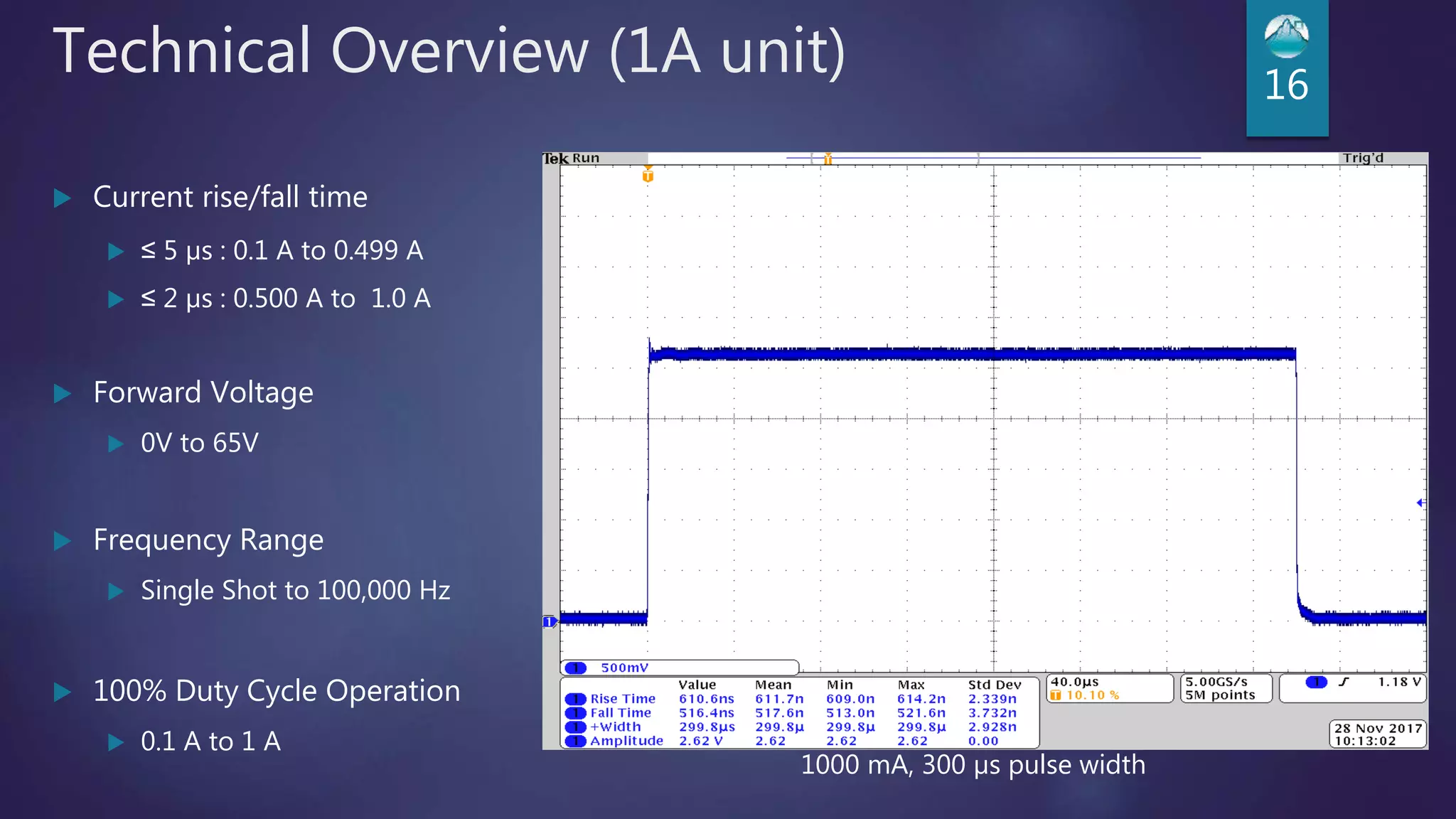

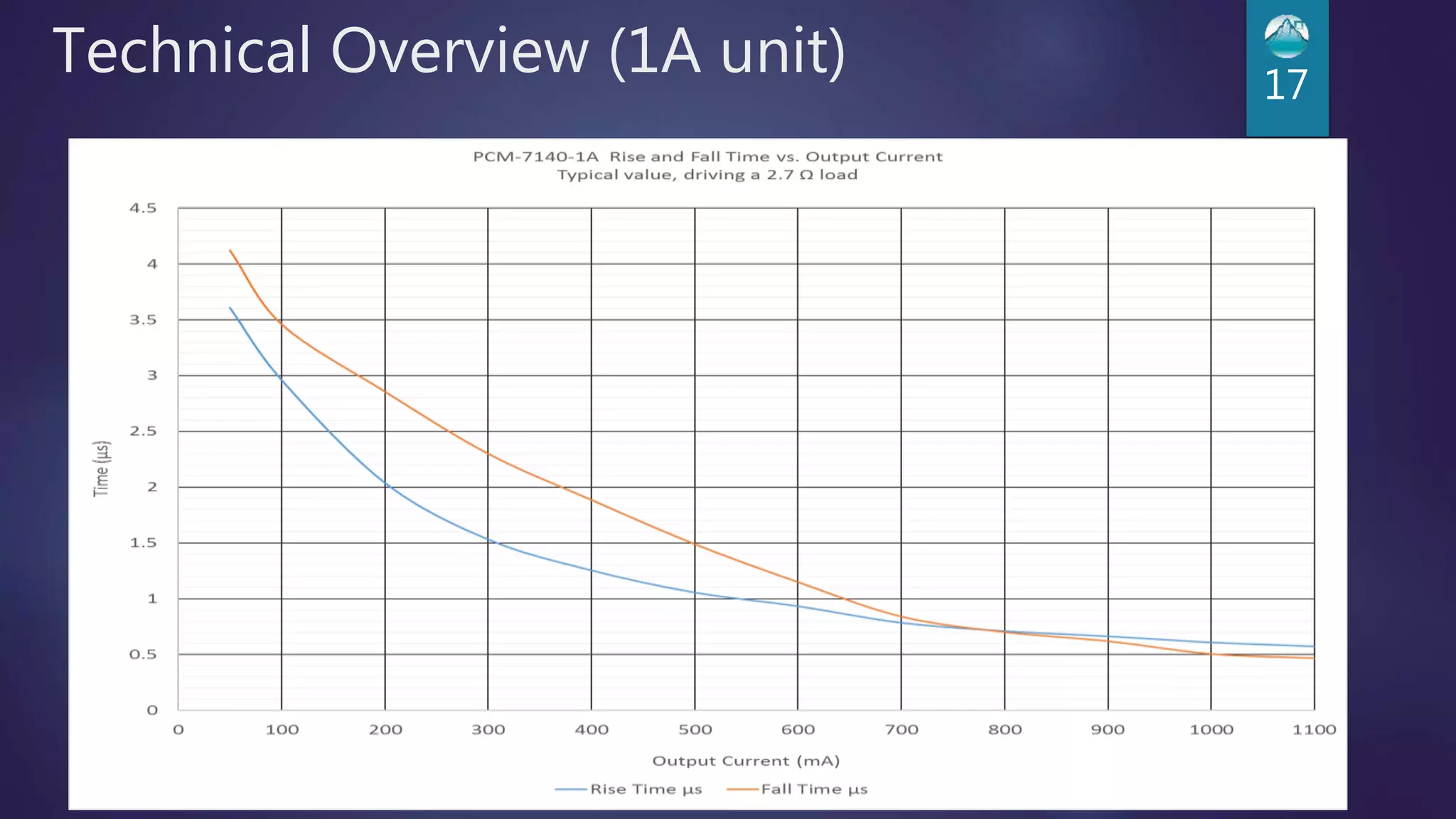

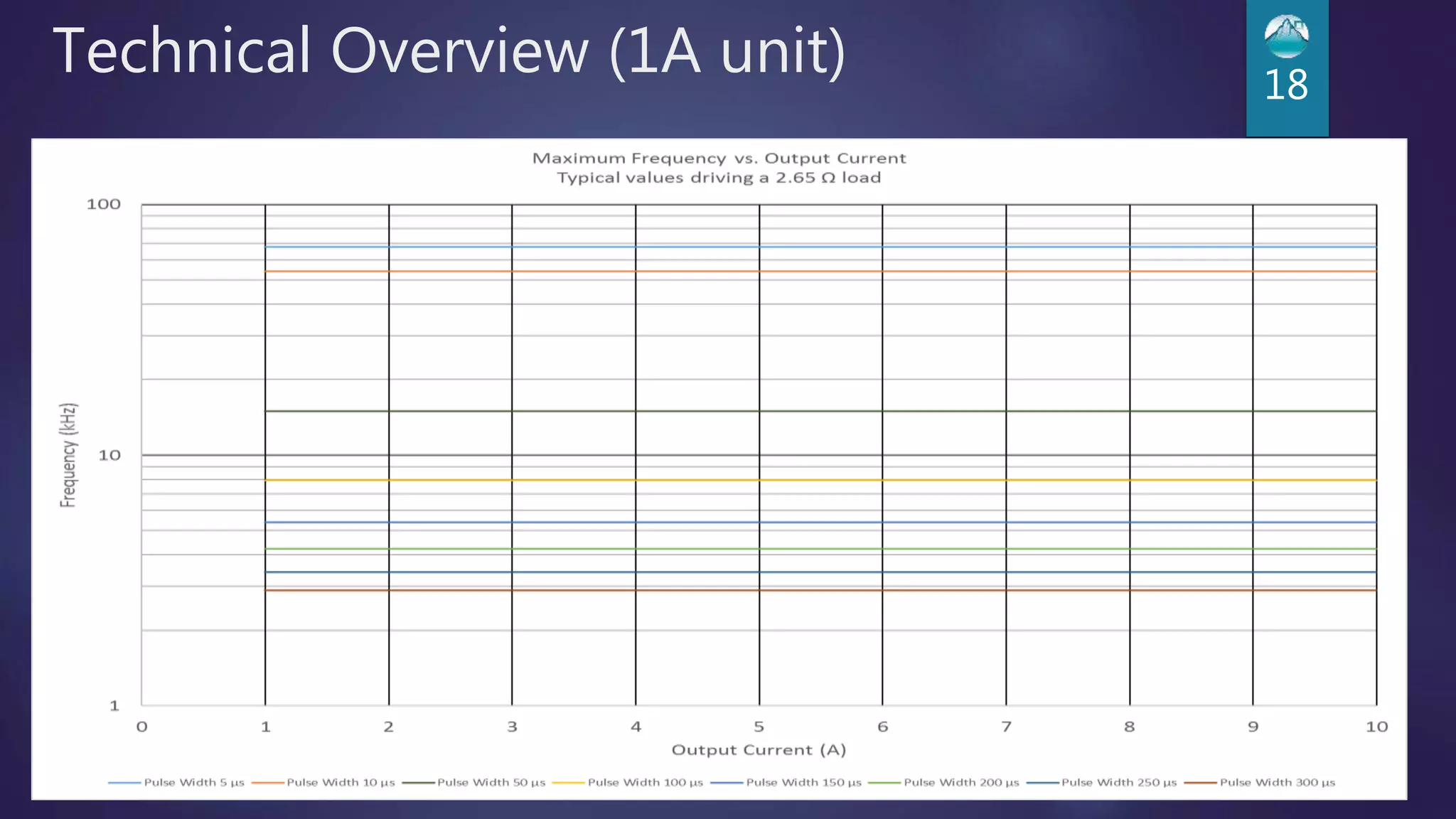

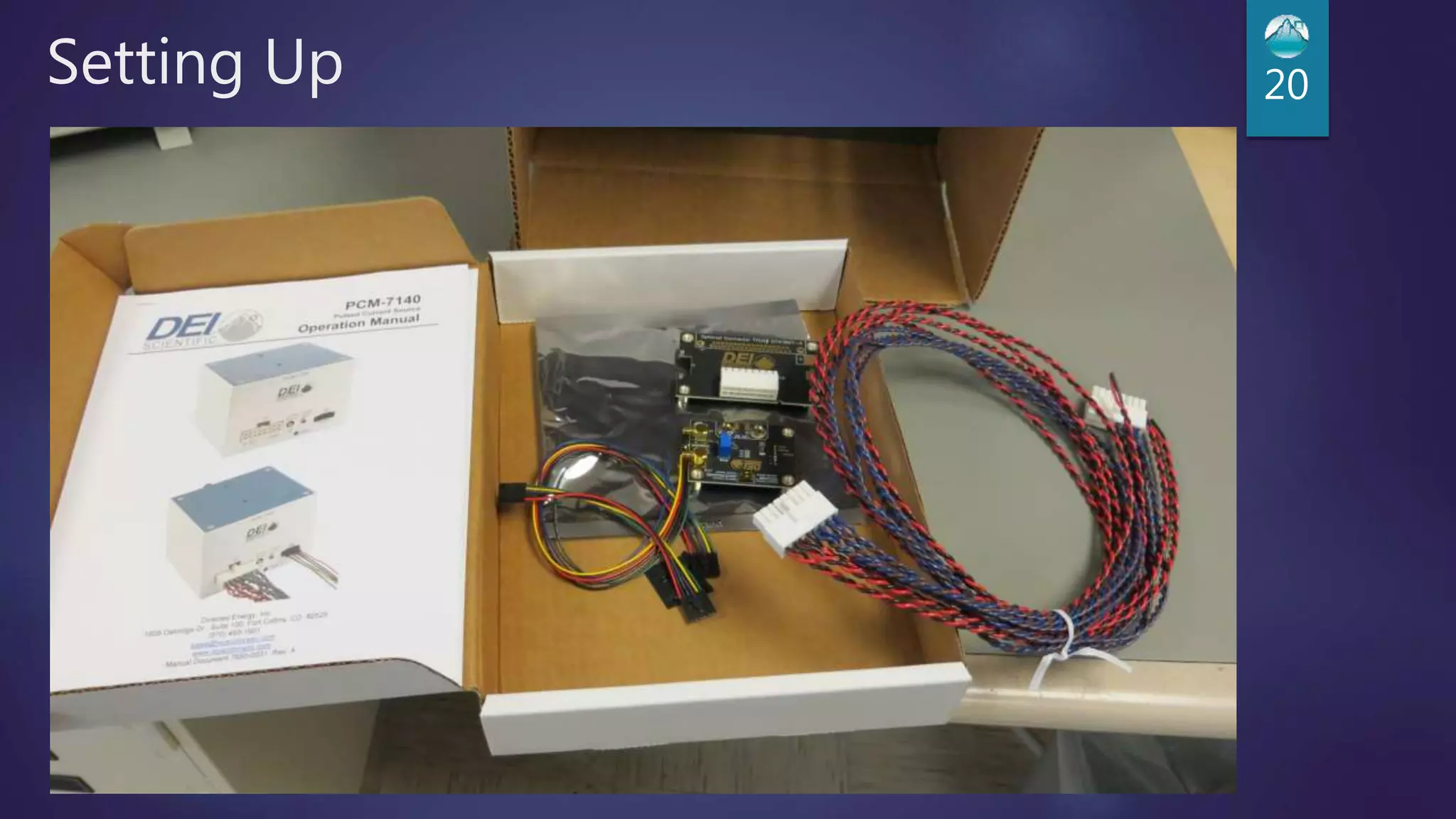

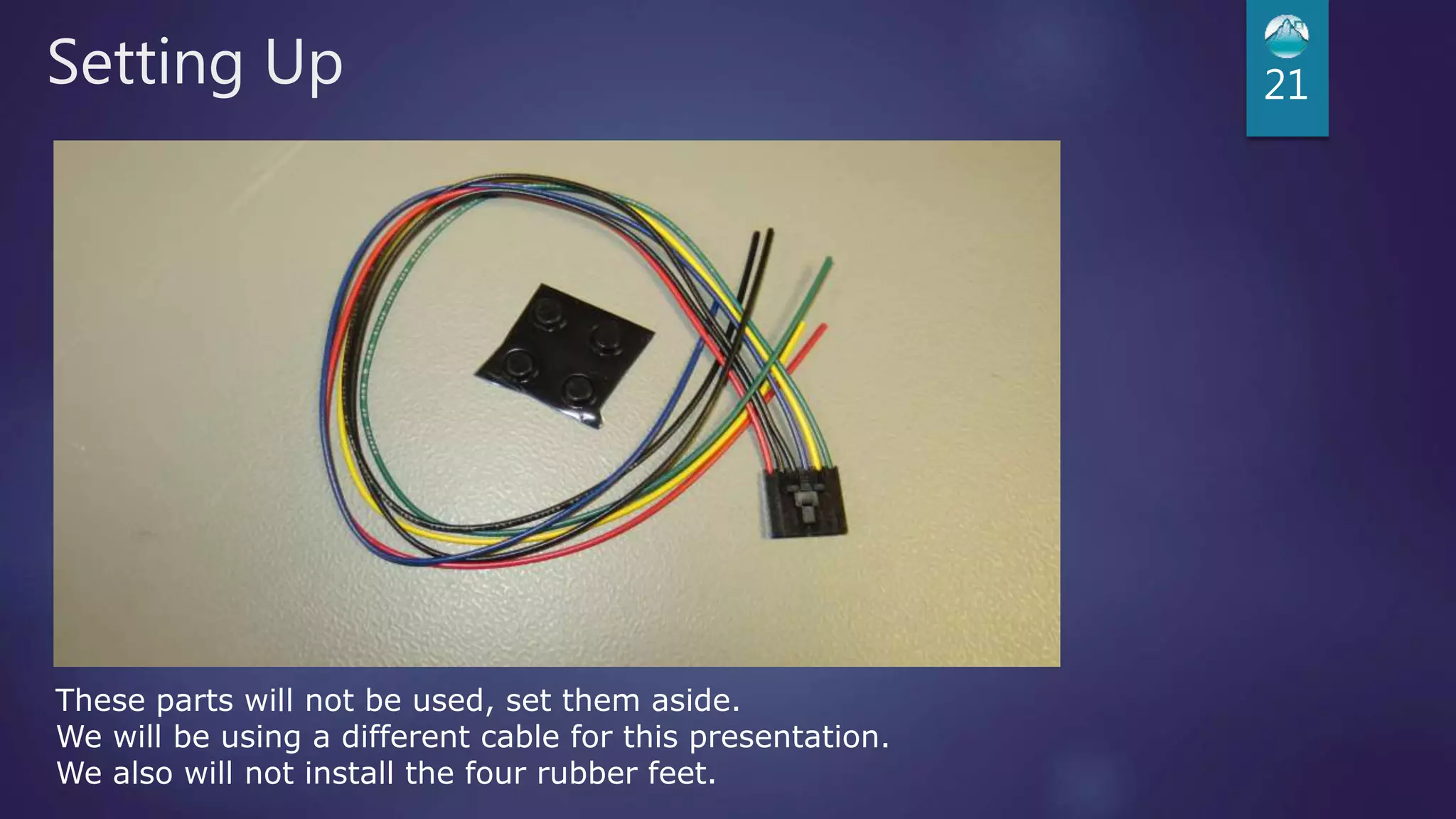

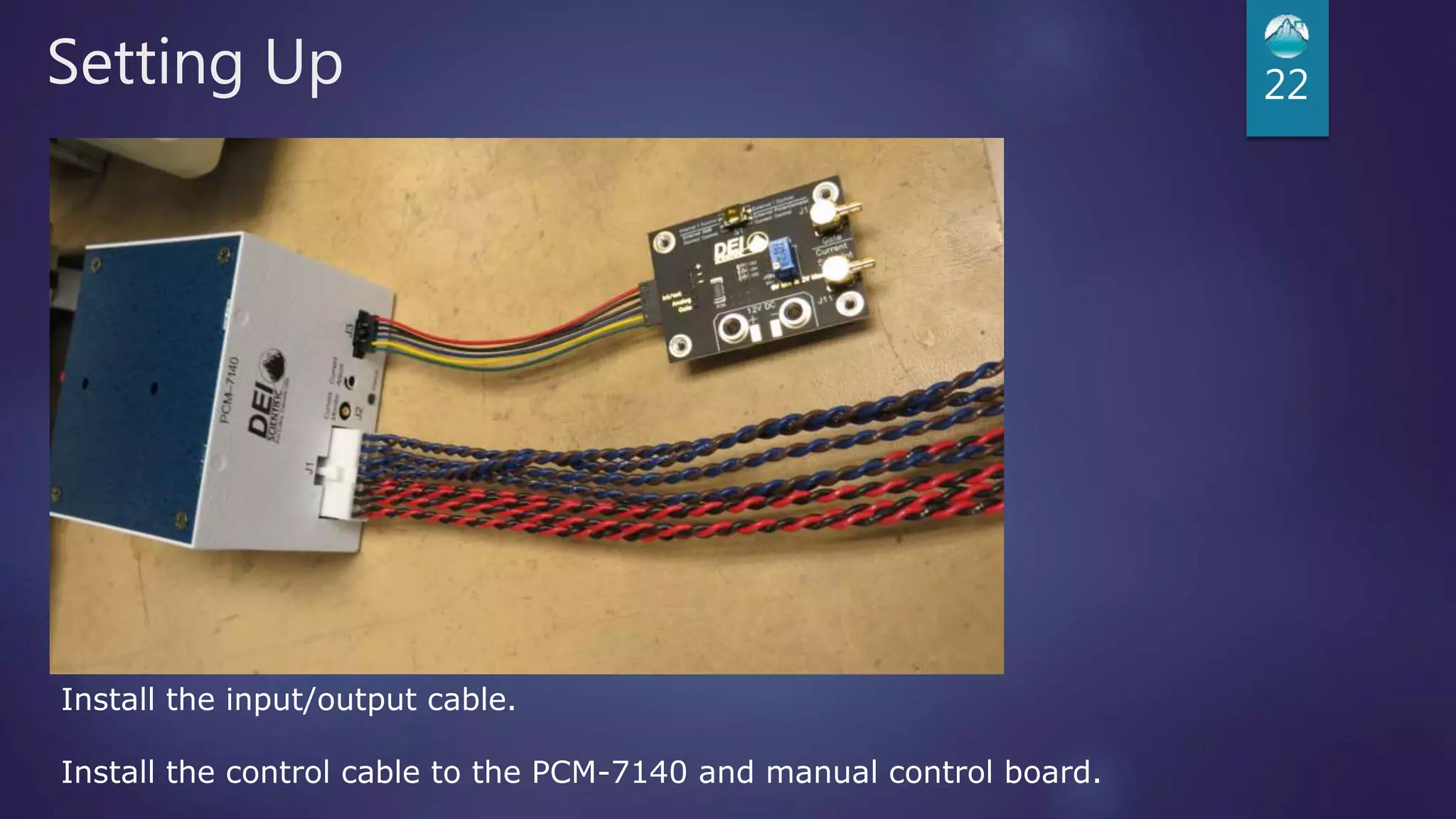

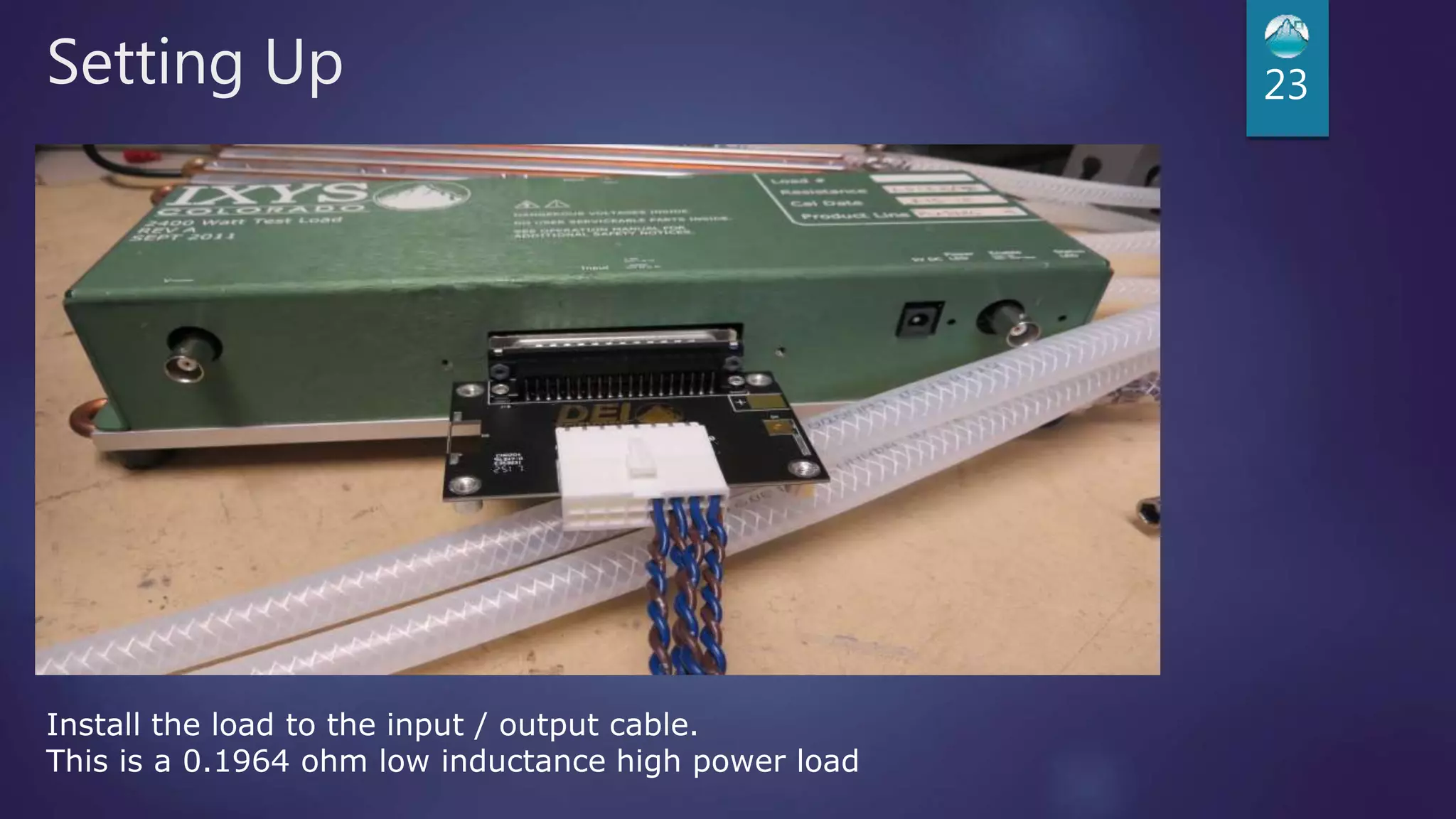

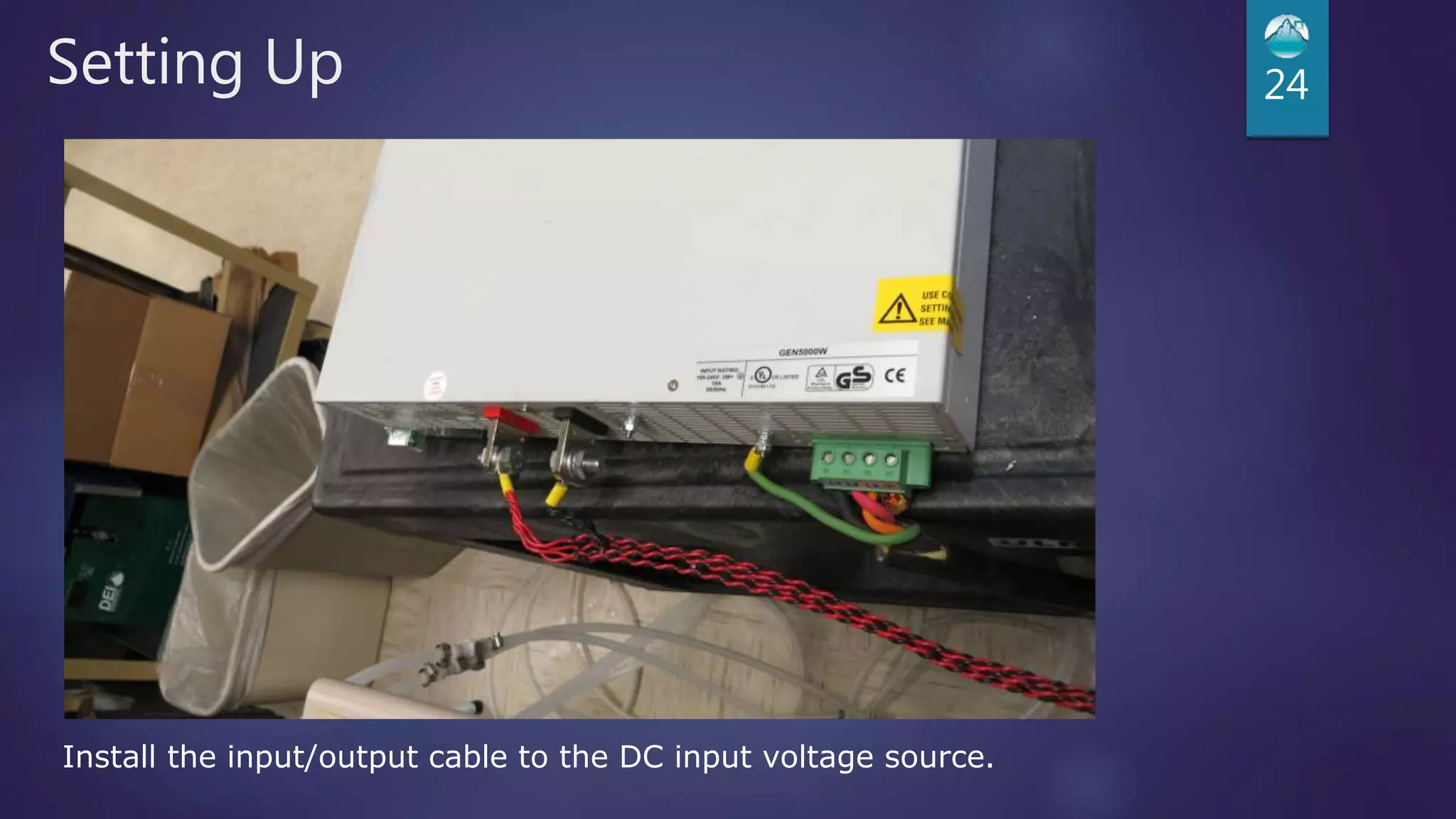

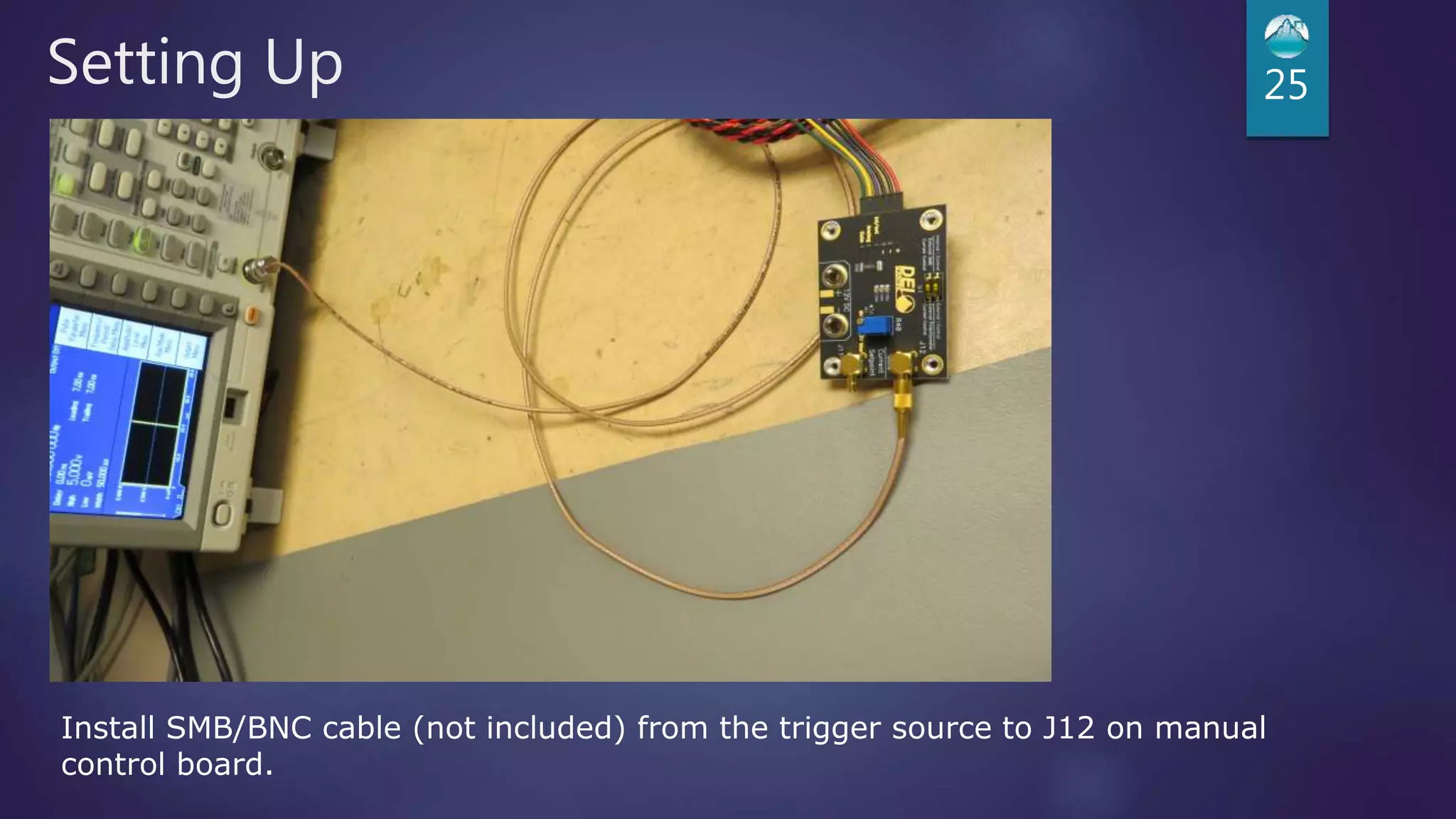

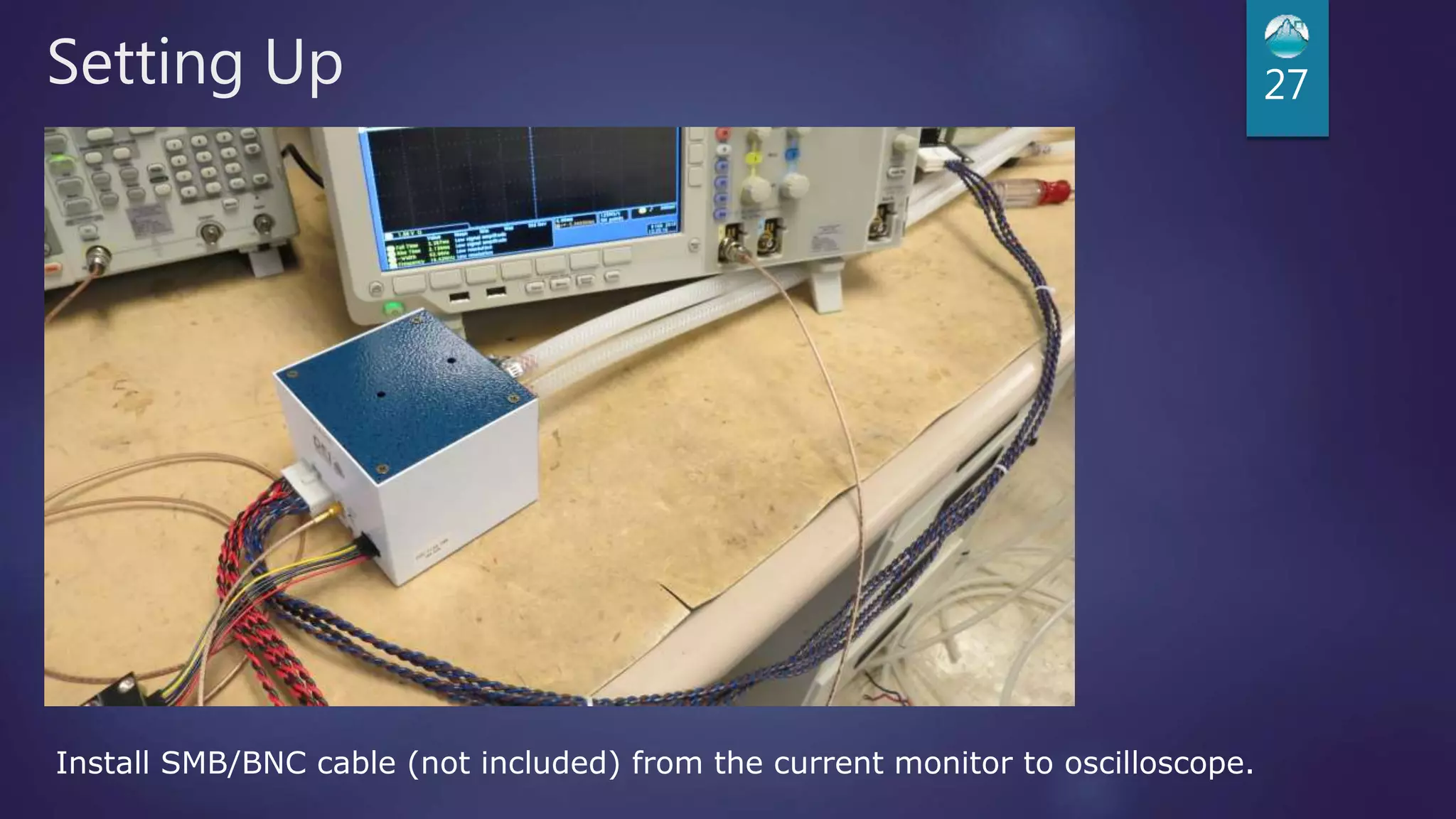

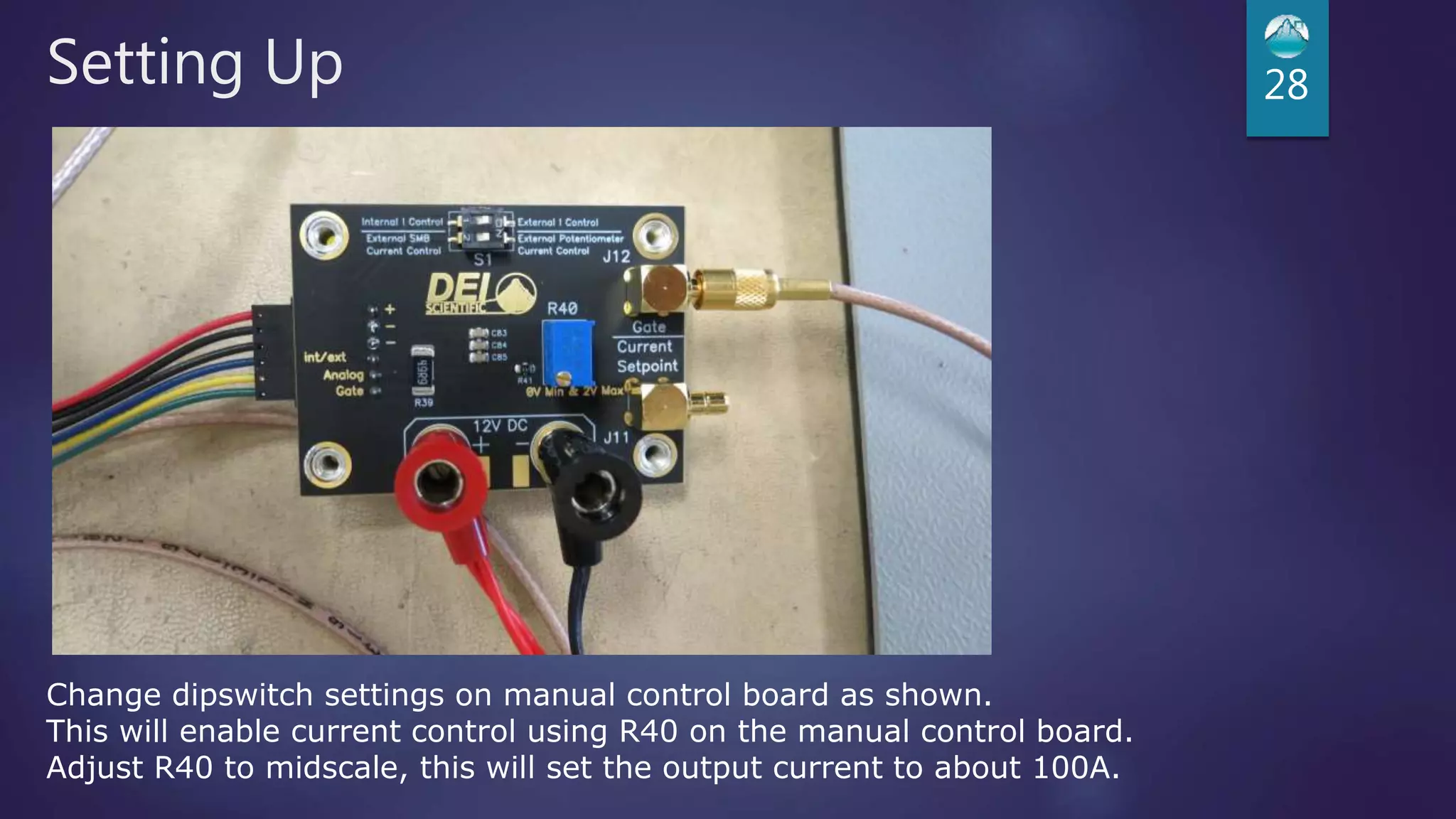

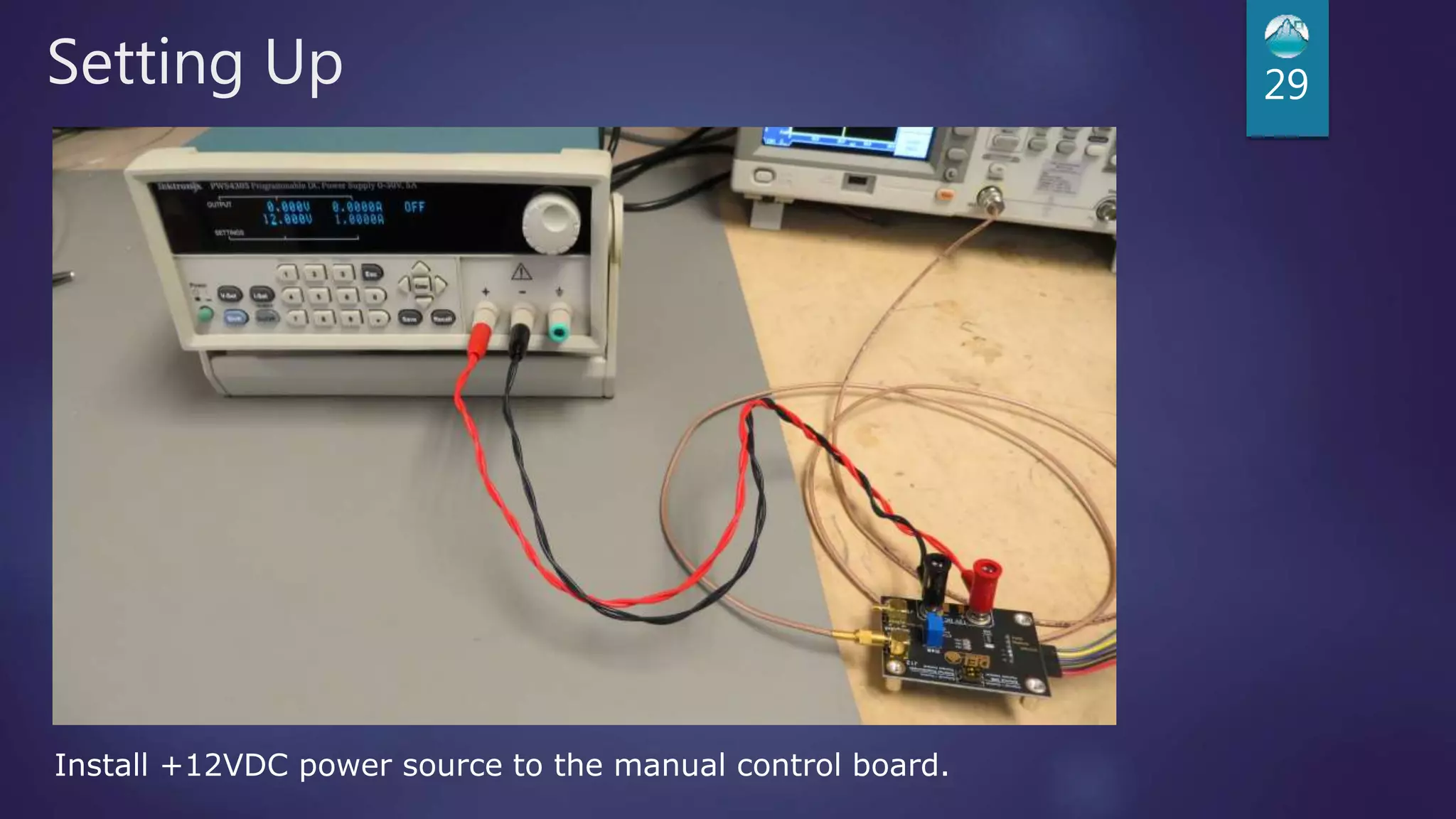

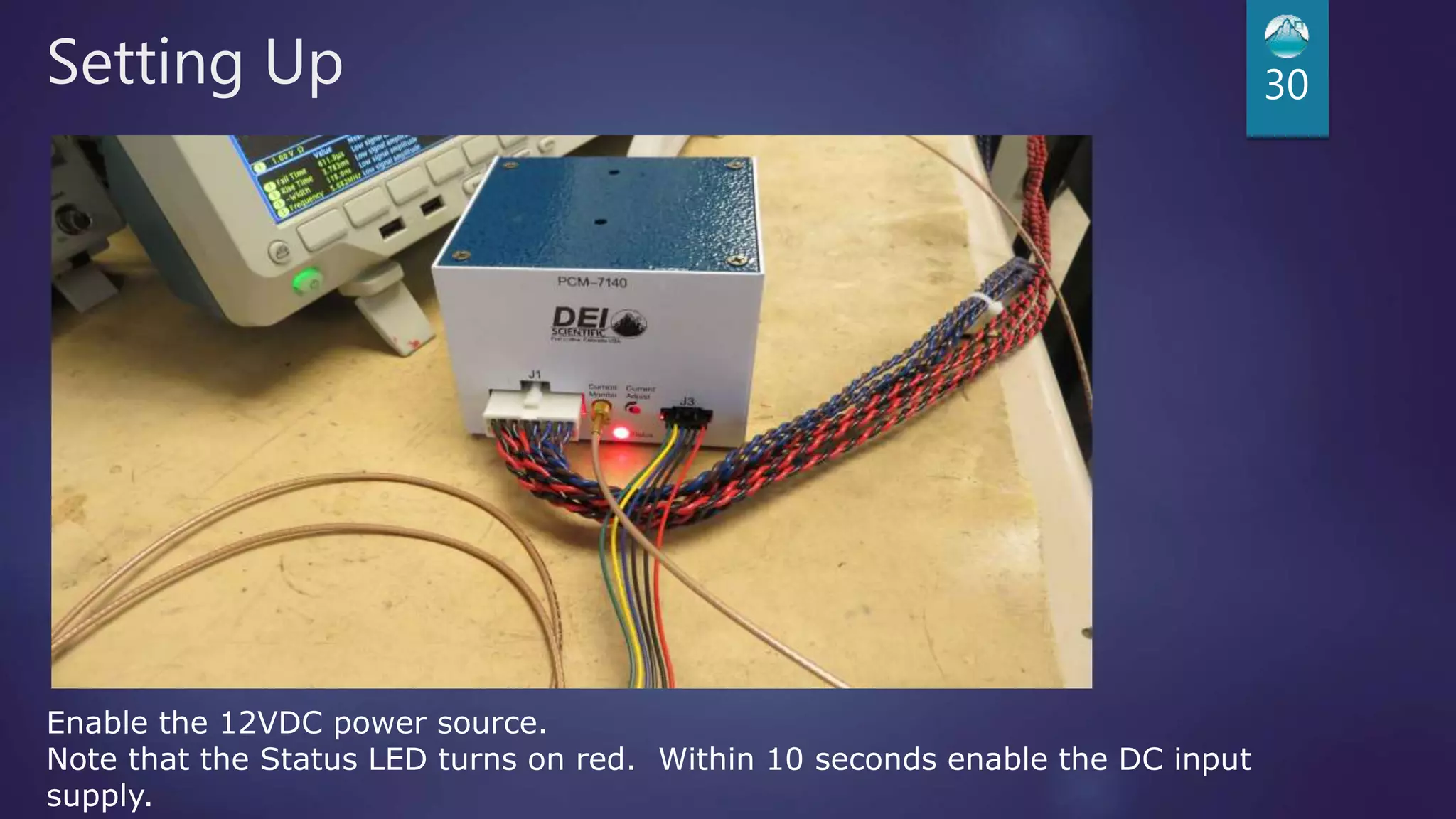

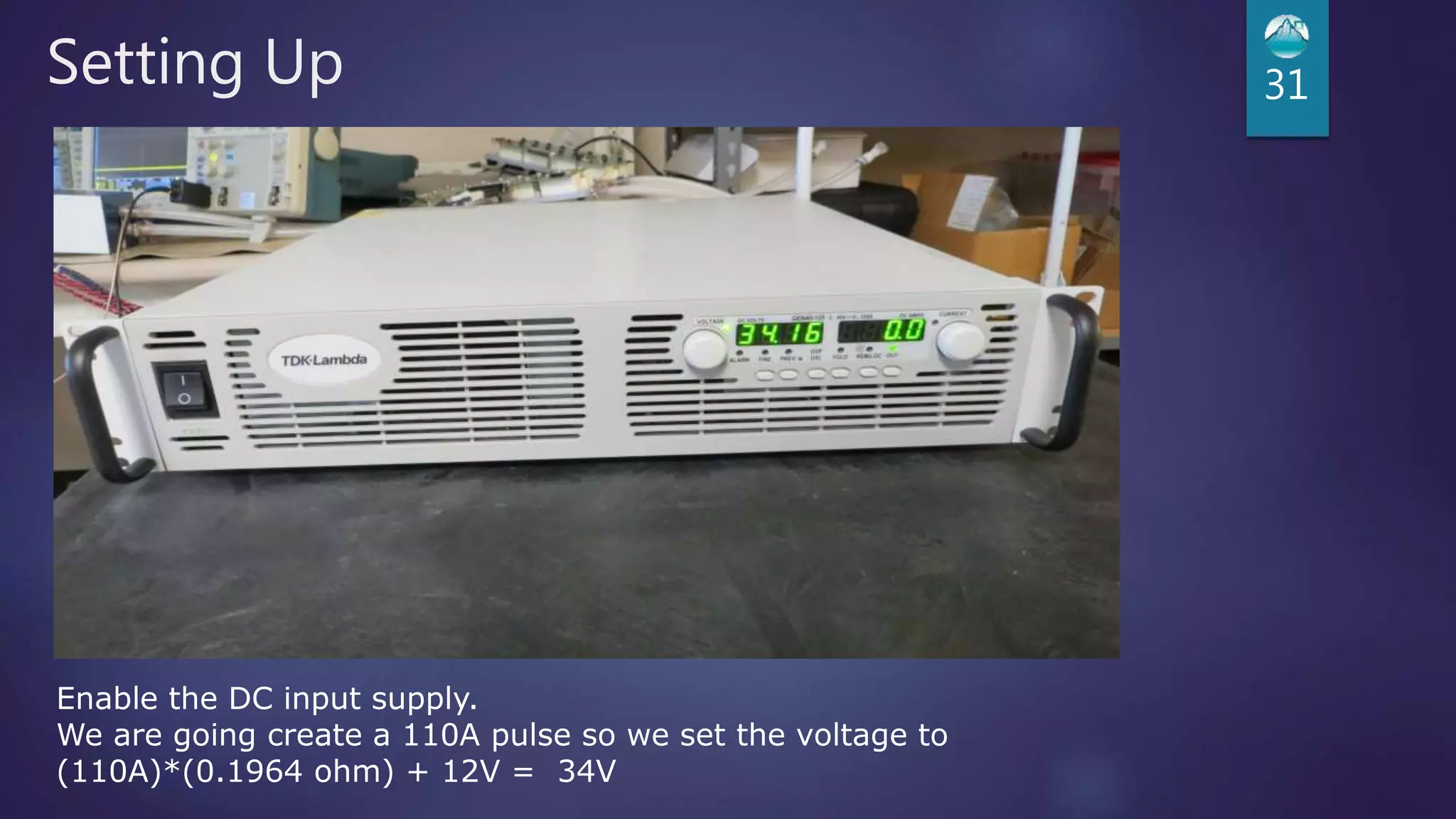

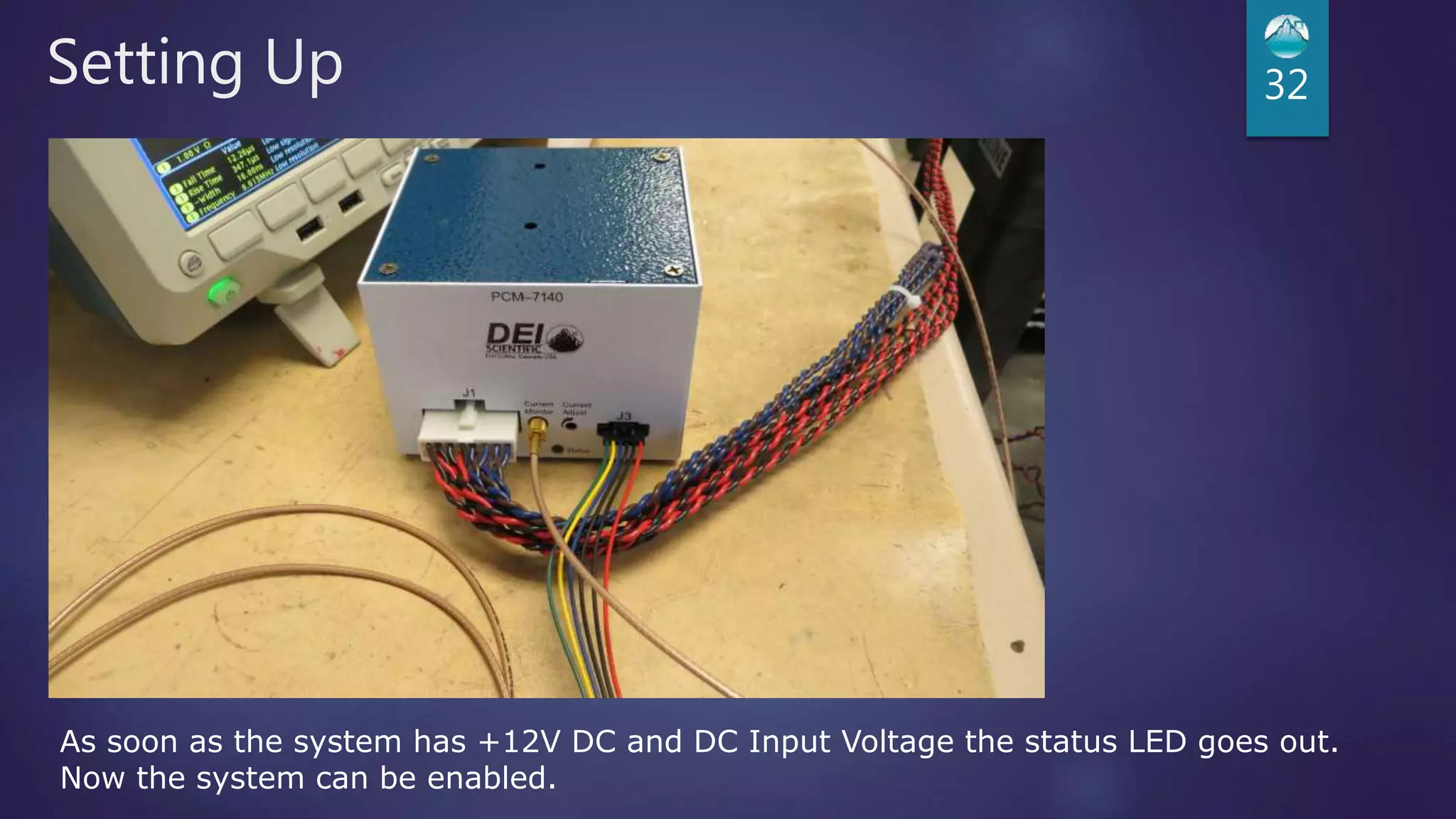

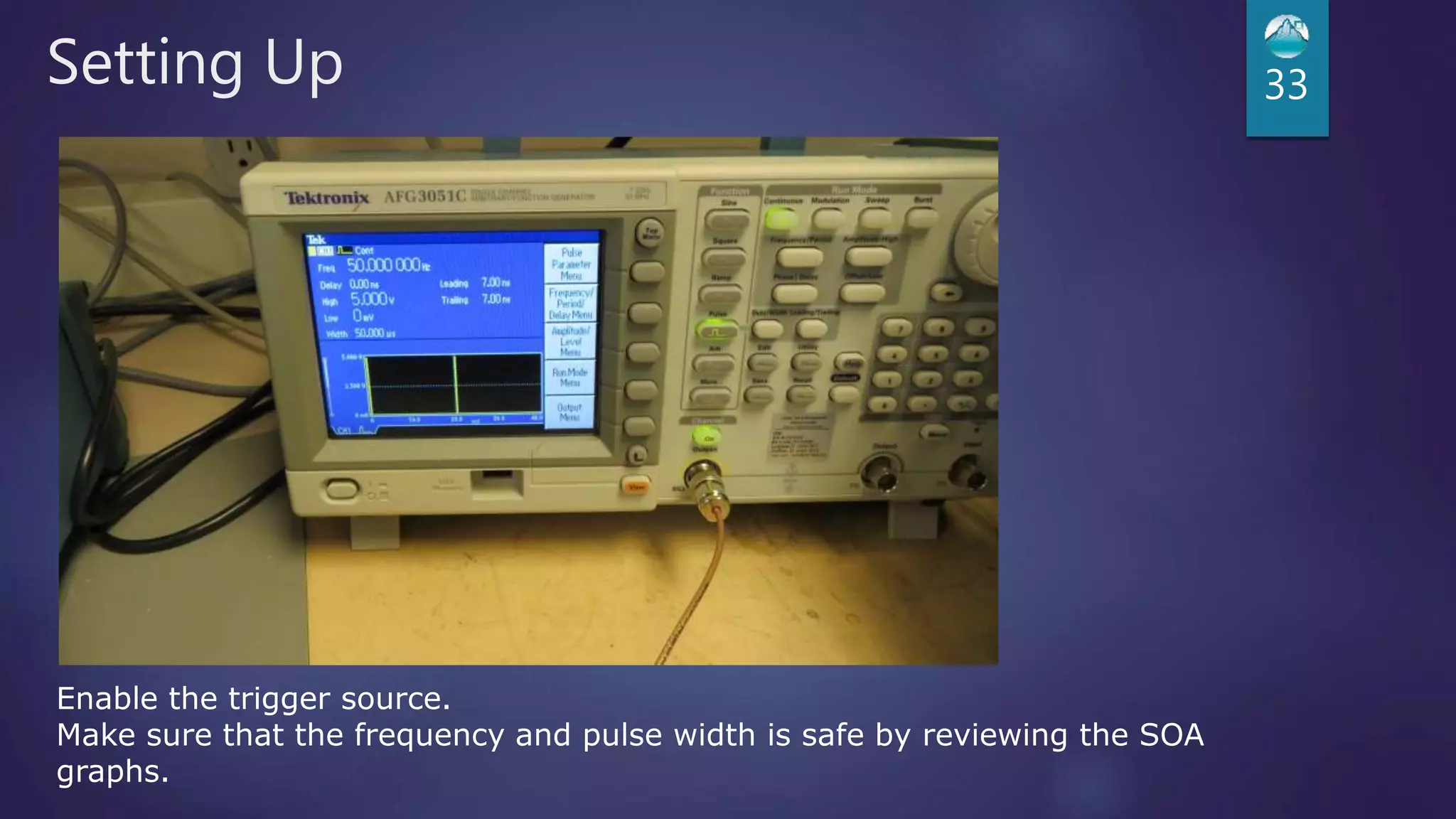

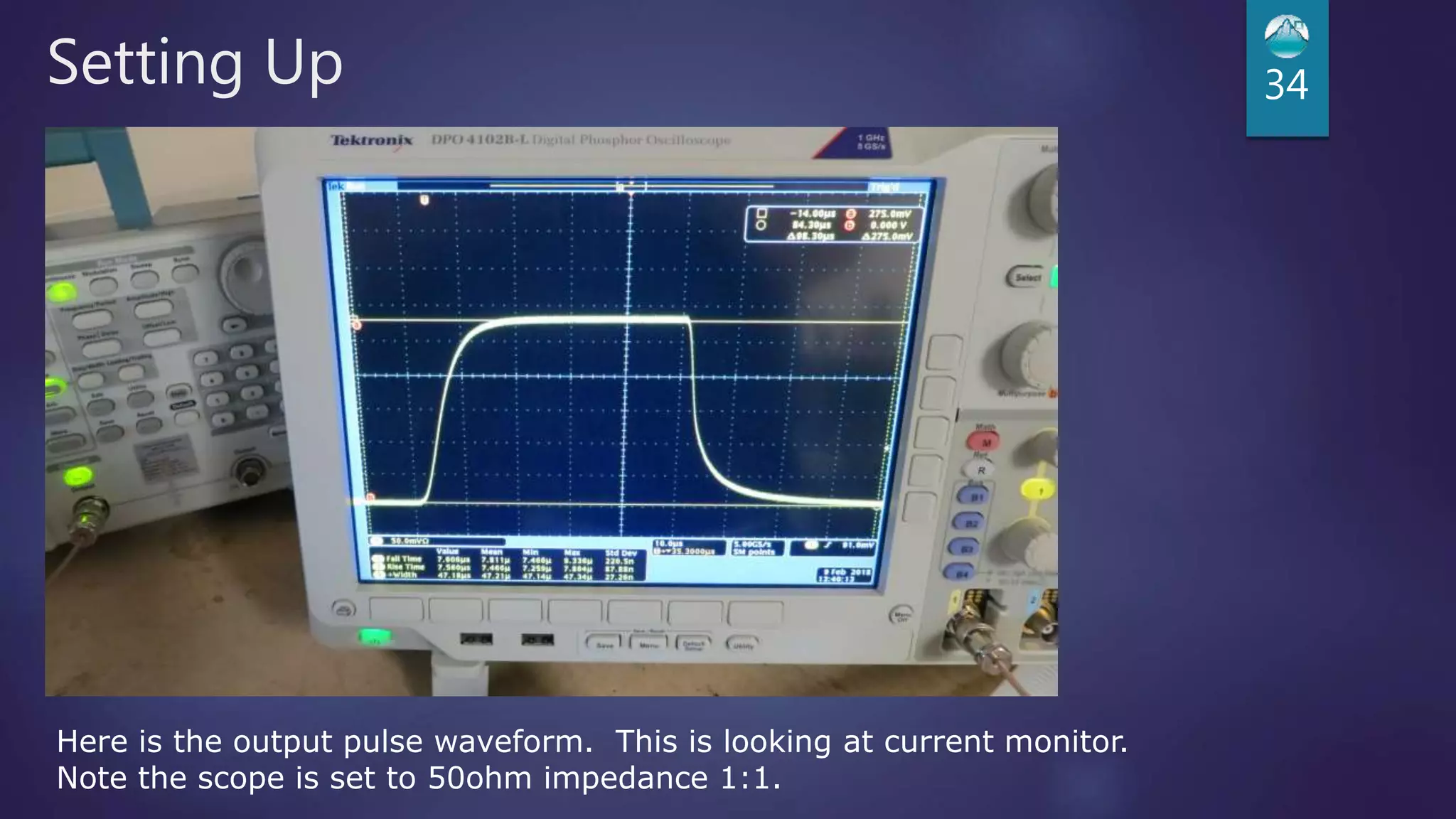

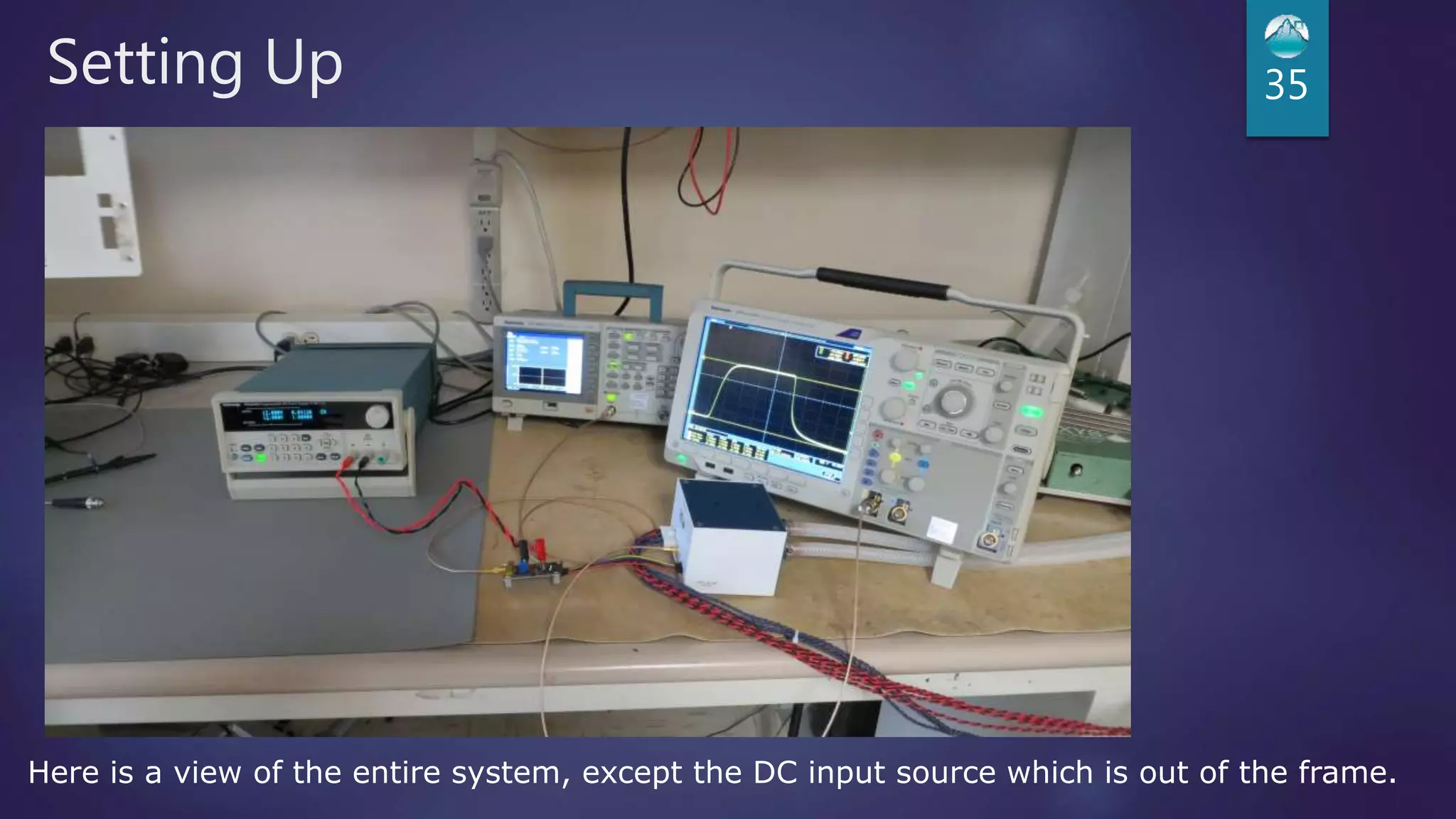

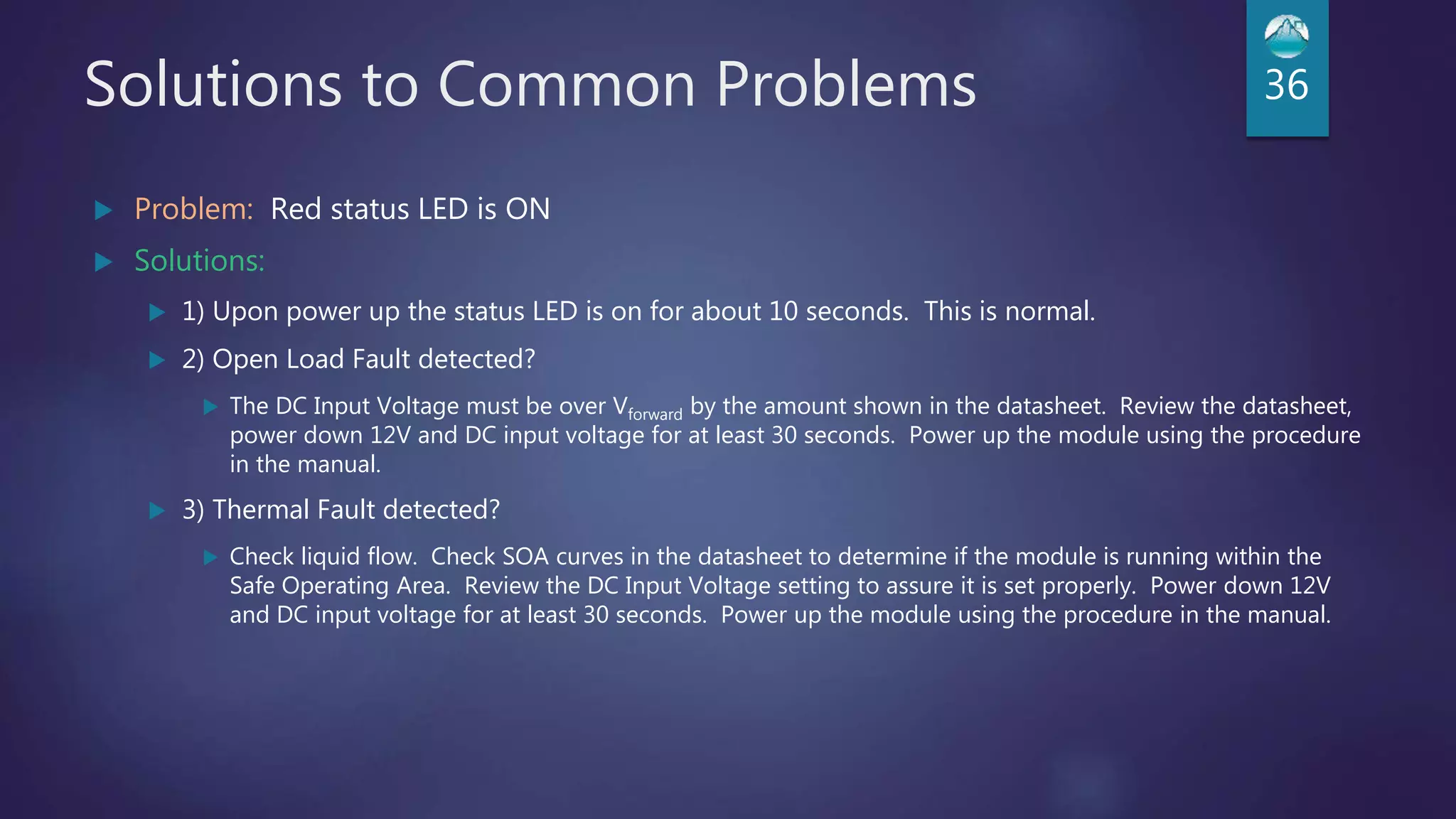

The pcm-7140 laser diode driver module by IXYS Colorado includes a control cable, manual, and various output boards for different current ranges (0.1a to 200a) with fast rise and fall times. It features a liquid cooling system, error detection for open load and over-temperature conditions, and is designed for high frequency and duty cycle operations. The document outlines setup instructions, troubleshooting steps, and example scenarios for effective operation.