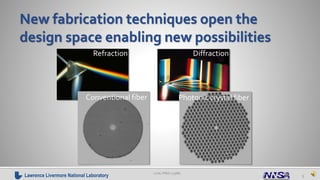

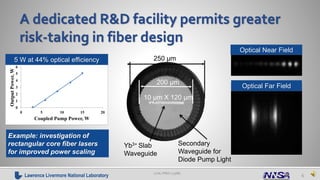

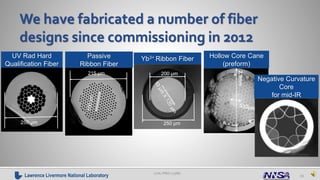

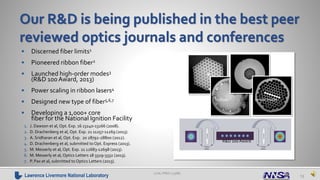

Lawrence Livermore National Laboratory (LLNL) is conducting research on advanced fiber and fiber laser technologies for various applications, including industrial machining and medical uses. Their work includes developing low-loss, robust fibers capable of high power transport and creating different types of laser fibers, such as hollow core and UV radiation hard fibers. LLNL is open to collaboration on innovative optical fiber designs that can address specific challenges in various fields.