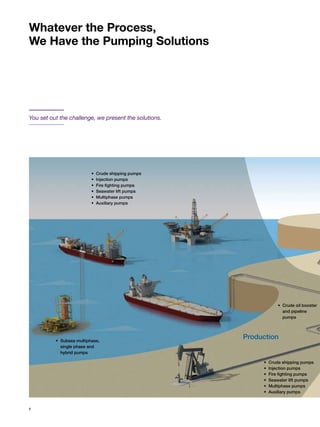

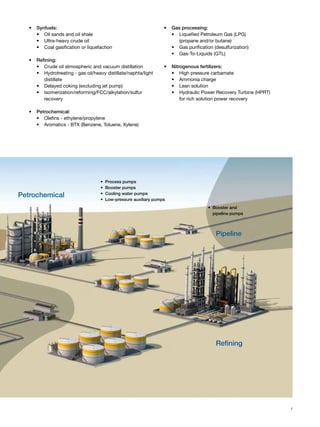

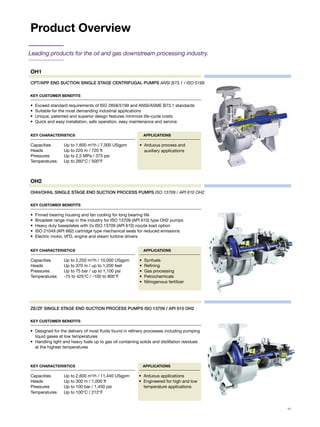

This document provides an overview of pumping solutions from Sulzer for the oil and gas downstream processing industry. It summarizes Sulzer's expertise and global footprint in manufacturing and servicing pumps. A wide range of pump products are described, including end suction pumps, vertical pumps, between bearing pumps, multistage pumps, barrel pumps, and vertical turbine pumps. These are suited for applications in production, refining, pipelines, petrochemicals, and fertilizers.