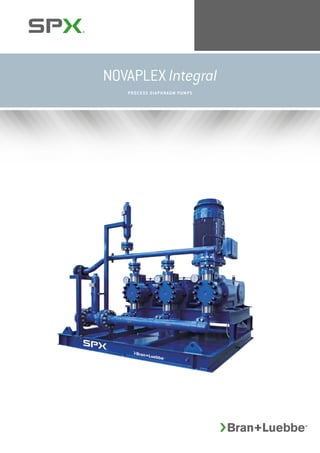

The Novaplex Integral is a diaphragm pump that uses hydraulically actuated diaphragms rather than direct contact between the crank gear and process fluid. The diaphragms separate the hydraulic fluid from the pumped liquid to ensure zero leakage. Novaplex Integral pumps can handle high pressures and flow rates, making them suitable for critical installations. They use double diaphragms with position control and leak detection for safety.