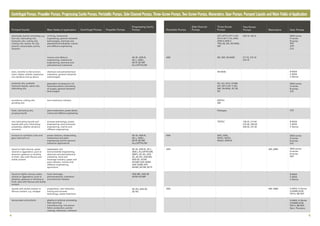

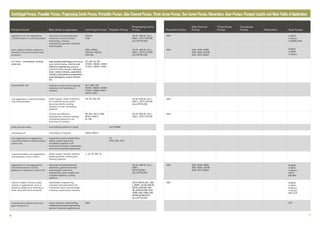

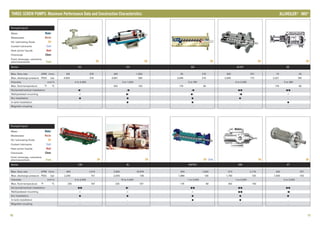

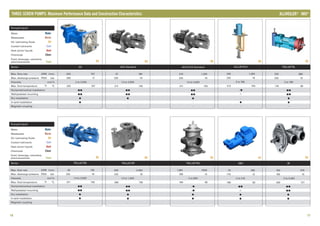

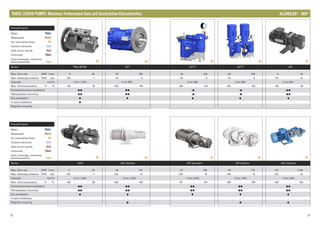

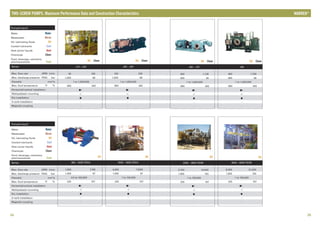

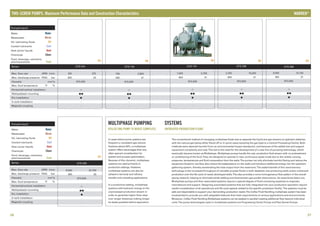

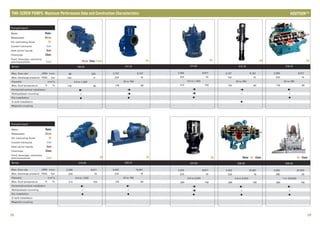

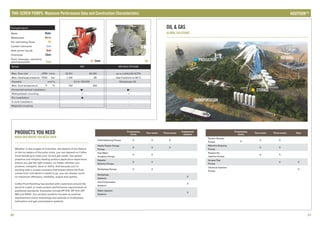

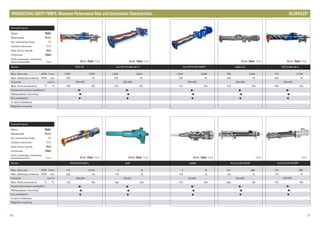

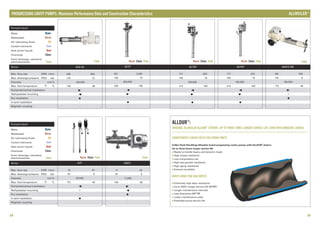

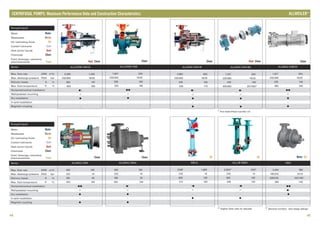

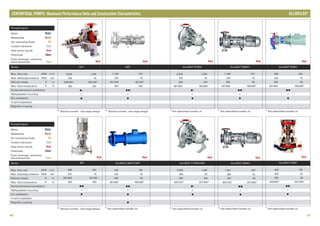

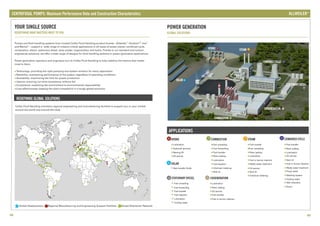

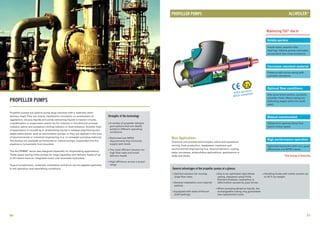

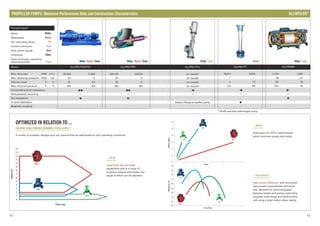

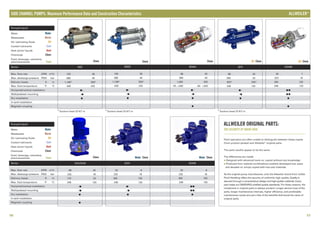

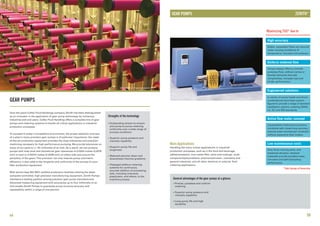

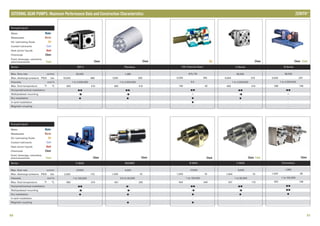

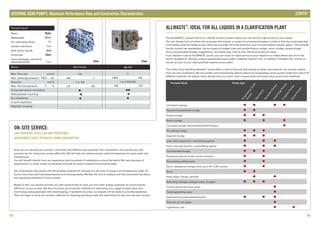

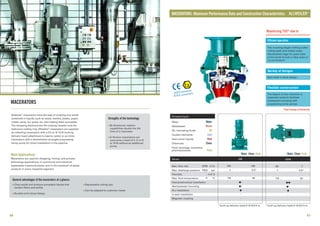

The document provides an overview of products from Colfax Fluid Handling for various industries. It describes their portfolio of pump brands including Allweiler, Houttuin, Imo, Warren and Zenith. The document then provides details on their various pump technologies for applications in industries like oil and gas, power generation, chemical processing, mining, pulp and paper, wastewater, food and beverage and others. It lists the main pumped liquids and fields of application for different pump types including centrifugal pumps, propeller pumps, progressing cavity pumps, peristaltic pumps, side channel pumps, three-screw pumps, two-screw pumps, macerators and gear pumps. Contact information and addresses for