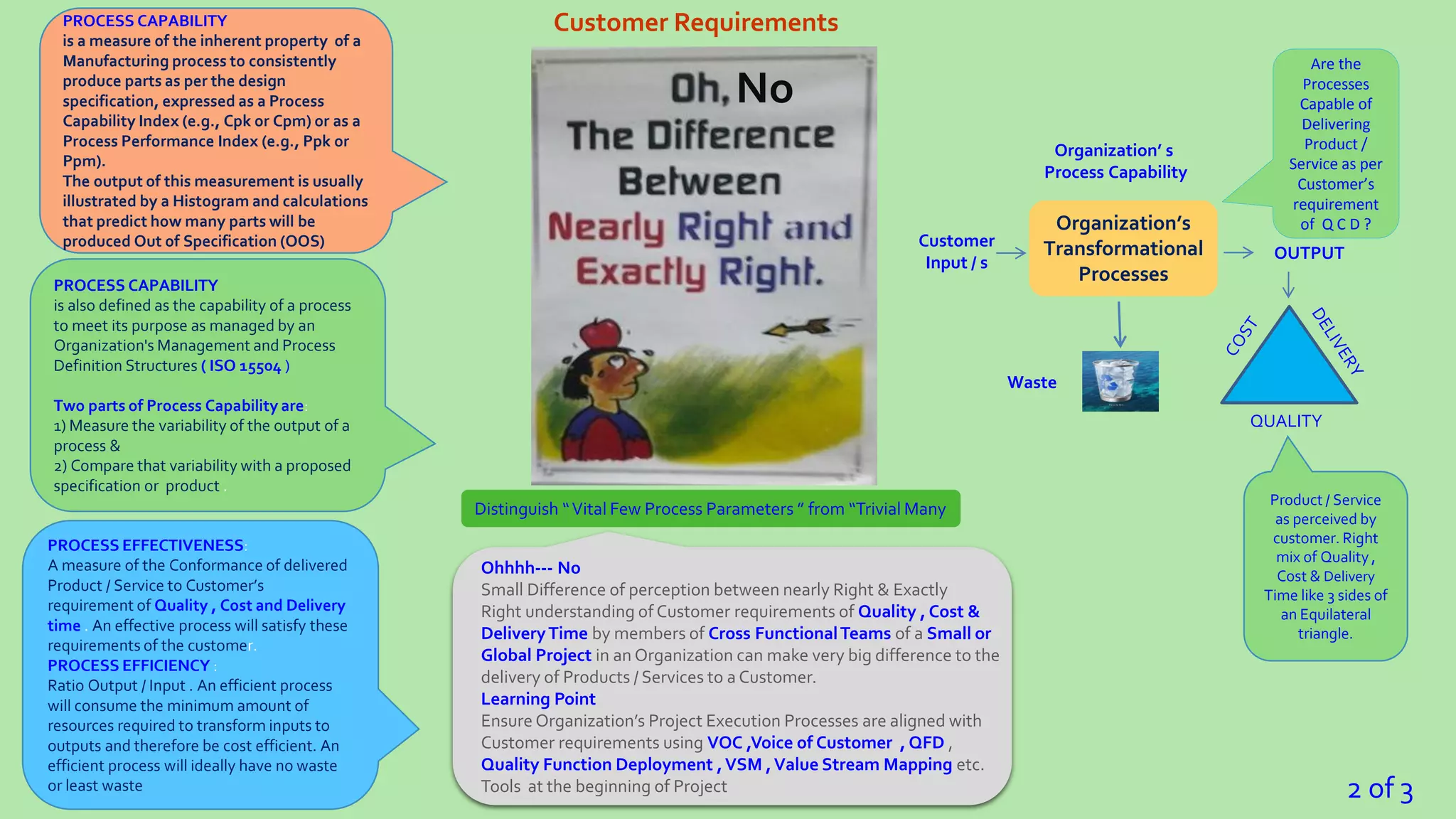

This document discusses concepts related to process effectiveness, efficiency, and capability. It defines process effectiveness as satisfying customer requirements for quality, cost, and delivery time. Process efficiency is defined as the ratio of output to input, with an efficient process having minimal waste. Process capability is defined as a process's ability to meet its purpose as defined by an organization's management structures, and involves measuring process variability and comparing it to specifications. The document provides formulas for calculating process capability indices like Cp, Cpk, Pp, and Ppk and explains when each would be used.