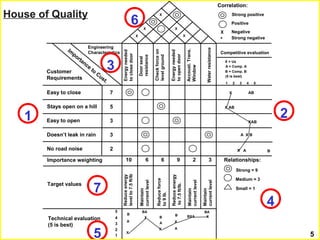

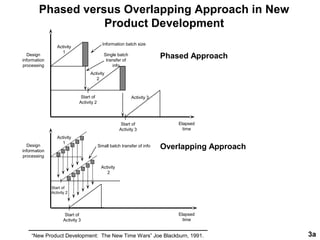

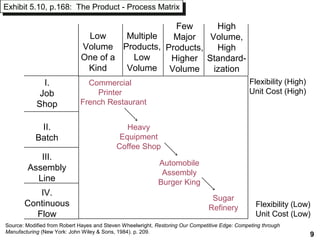

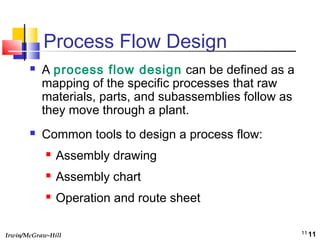

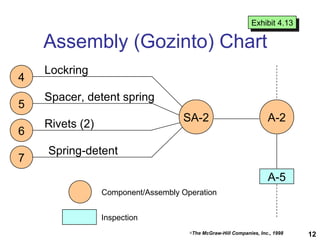

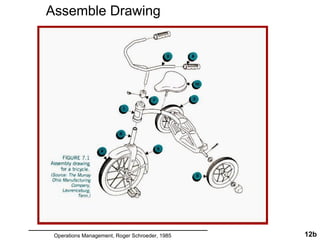

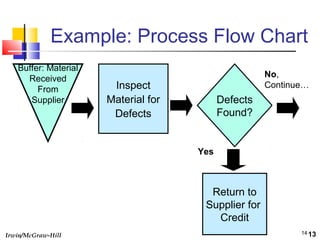

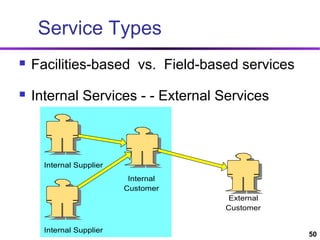

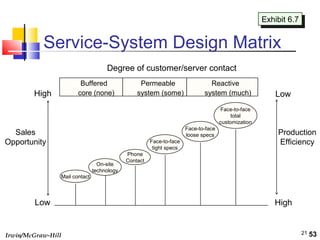

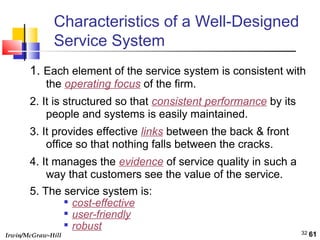

The document discusses various aspects of product design and service operations management. It covers topics such as concept development, quality function deployment, concurrent engineering, process flow design, types of processes and structures, service strategy and classifications. The key stages of product design include concept development, product planning, engineering and pilot production. Quality function deployment involves using inter-functional teams to understand customer needs. Concurrent engineering aims to reduce time to market through overlapping activities. Process flows can be job shop, batch, assembly line or continuous and depend on volume and standardization. Services differ from goods in being intangible, perishable and having simultaneous production and consumption.