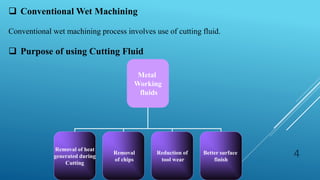

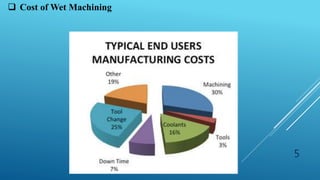

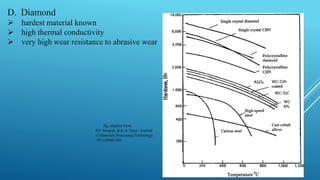

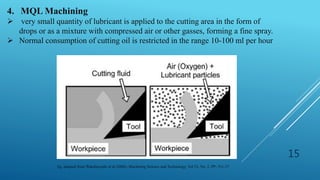

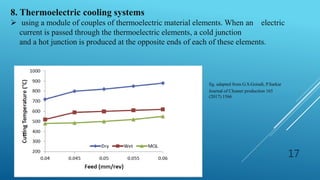

This seminar report discusses dry machining as an alternative to conventional wet machining. Wet machining utilizes cutting fluids that generate waste and pollution. Dry machining aims to eliminate cutting fluids. However, dry machining is challenging due to high temperatures that reduce tool life and damage workpiece surfaces. Strategies to enable successful dry machining include using advanced tool materials and coatings, minimum quantity lubrication, cryogenic cooling, and thermoelectric cooling. Dry machining has applications in machining various materials and processes, and offers advantages like waste elimination and improved productivity.