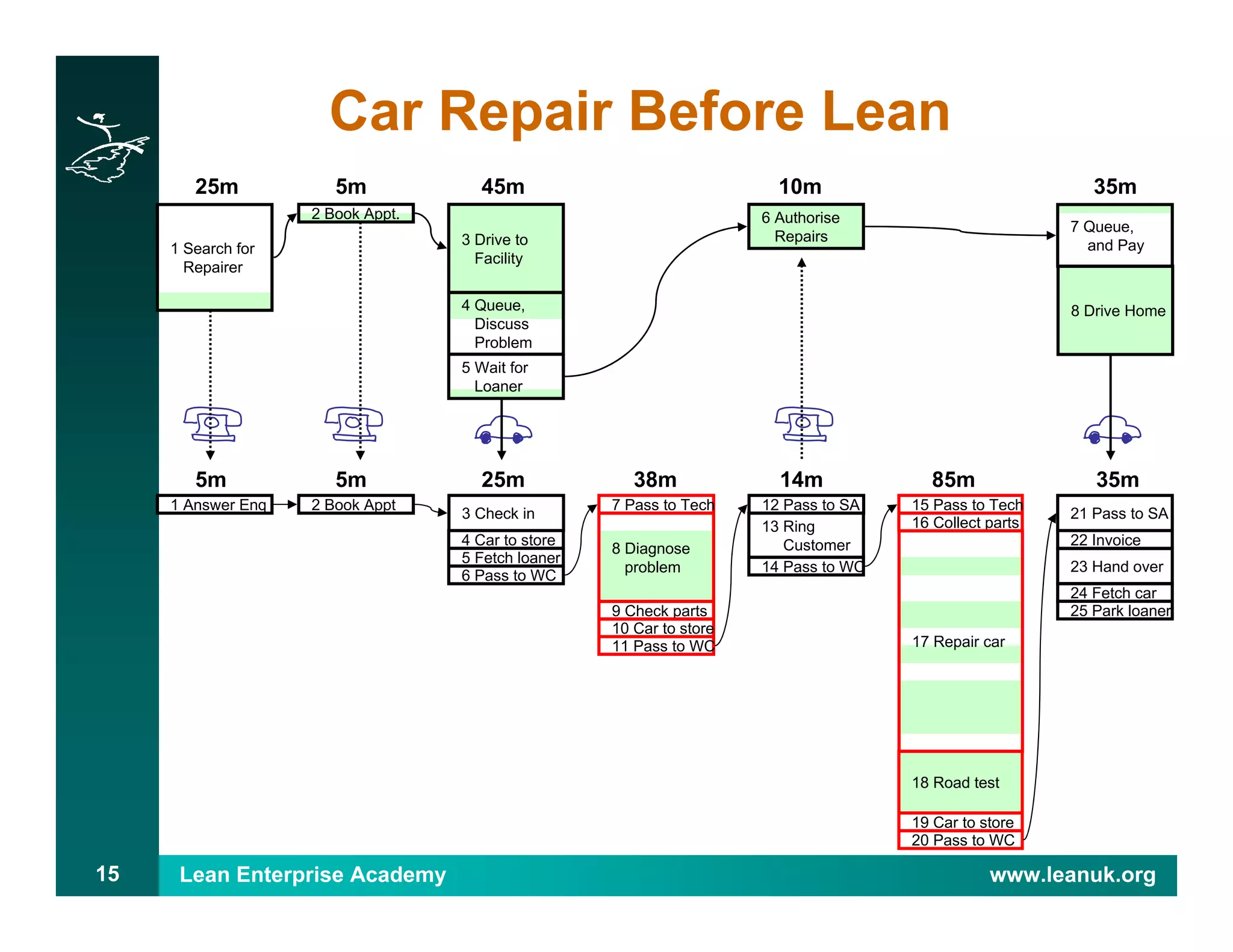

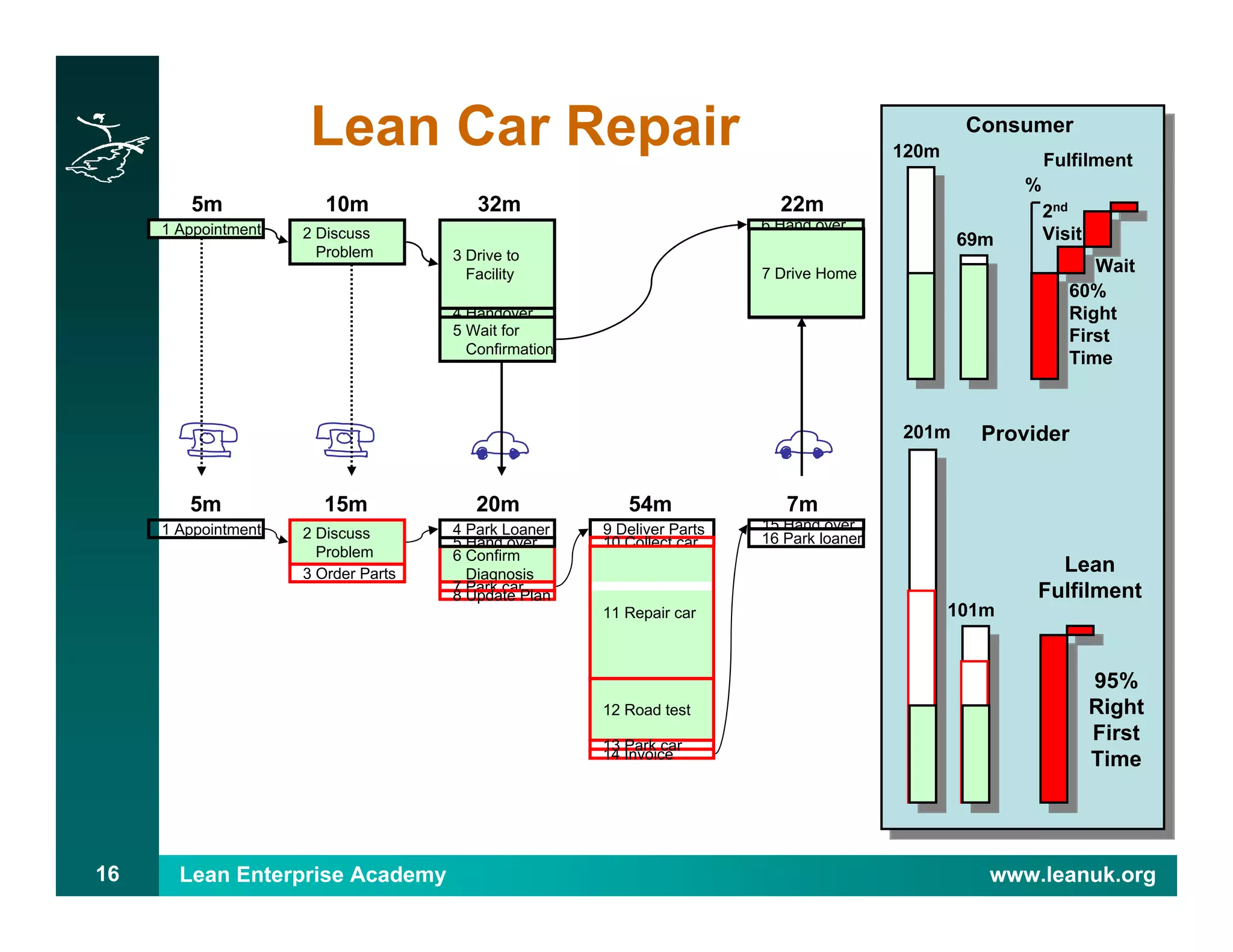

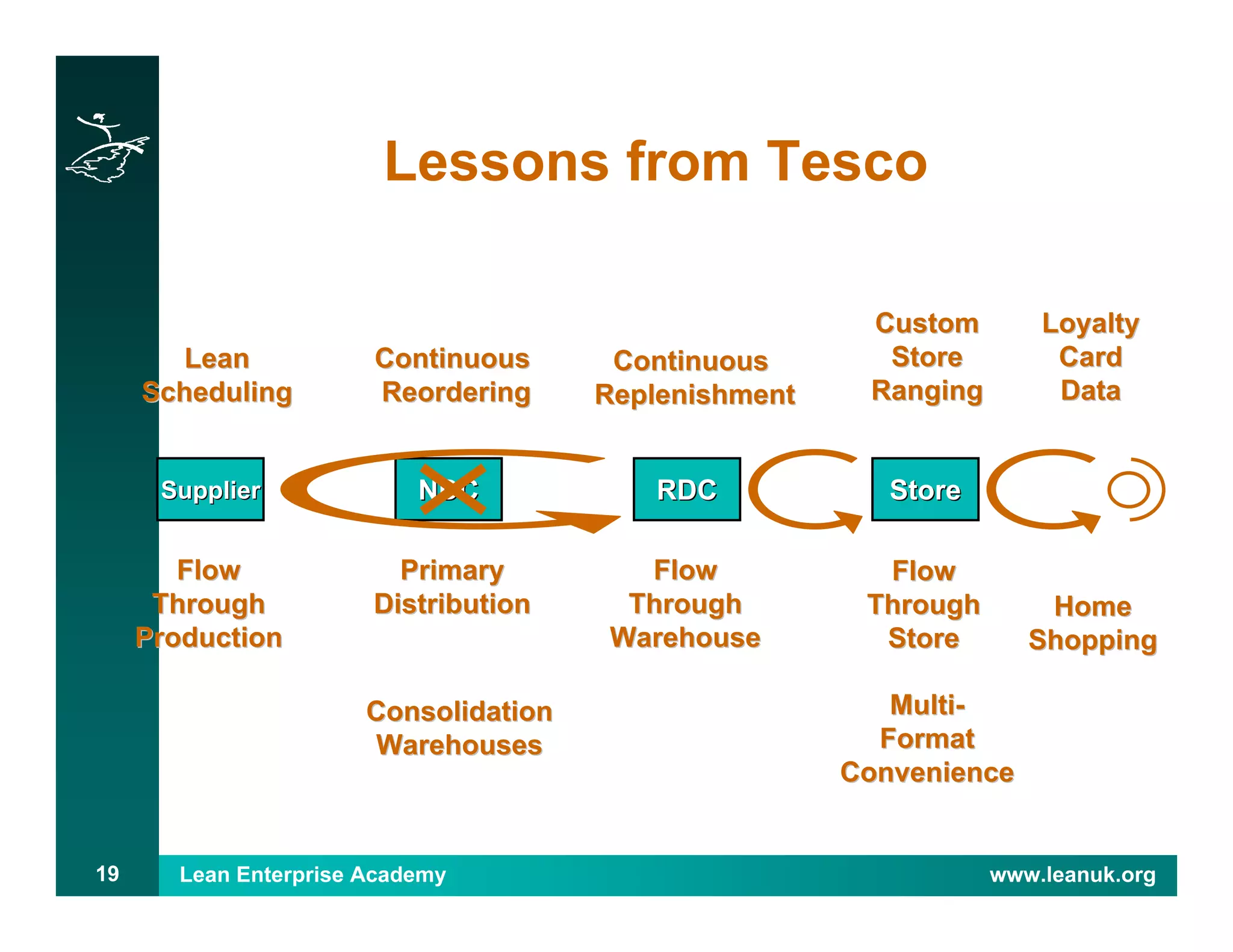

The document outlines lean principles for improving manufacturing and consumption processes, emphasizing value specification from the consumer's perspective and eliminating waste. It highlights the importance of understanding changing consumer behaviors and expectations, as well as the necessity for responsive production and distribution systems. Key takeaways include the significance of collaboration with customers, the need for rapid replenishment, and the evolving nature of market channels and fulfillment strategies.