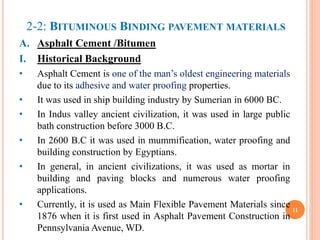

This document provides an overview of bituminous binding pavement materials, focusing on definitions, types, sources, and physical tests related to asphalt cement. It differentiates between asphalt and tar, discusses the historical usage of asphalt, and outlines the refining process and testing methods to evaluate asphalt's properties. Key topics include the types of bituminous binders, their classification, and the importance of grading asphalt for consistency in pavement construction.

![2-2: BITUMINOUS BINDING PAVEMENT MATERIALS

II. Sources of Asphalt Cement

• The two main sources of Asphalt Cement are:

• Natural Asphalt

• Petroleum Asphalt

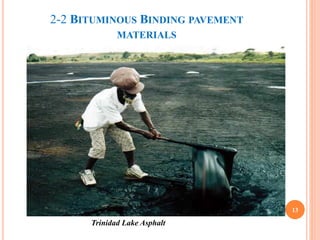

a. Natural Asphalt

Naturally exists in two forms:

1. As relatively soft asphalt material [Trinidad, Bermudez,

etc].

2. As hard, friable and black material in the veins of rocks or

impregnated in various stones; lime stone and sand stone.

[Western Canada].

12

Some of the predominant sources of Natural Asphalt includes; Trinidad

Asphalt Lake, Bermudez, Venezuela, etc.](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-12-320.jpg)

![2-2: BITUMINOUS BINDING PAVEMENT

MATERIALS

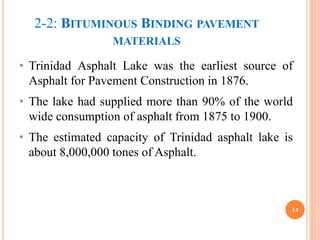

• Different sources of Crude Oil have different contents due to

the difference in geological formation.

• Accordingly, Crude Oils from different sources have different

Asphalt Content.

• One of the index used to measure the content of asphalt in

Crude Oil is American Petroleum Institute [API] Gravity.

• API Gravity =

16

141.5

Specific

Gravity

_ 131.5](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-16-320.jpg)

![2-2: BITUMINOUS BINDING PAVEMENT

MATERIALS

• API Gravity is an arbitrary expression of density of

materials expressed at 60oF.

• Some typical values include:

17

Substance Typical API Values

Water 10

Asphalt 5-10

Gasoline 55

Low API Gravity Crude Oil < 25 [yields high % Asphalt]

High API Gravity Crude Oil > 25 [yields low % Asphalt ]](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-17-320.jpg)

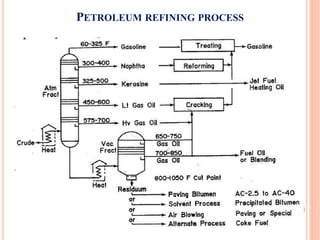

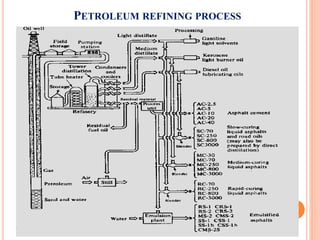

![2-2: BITUMINOUS BINDING PAVEMENT MATERIALS

Basic Refining Process:

• Crude Oil is heated in large furnace to above 340oC

and partially vaporized. The vapor is fed into

distillation tower where lighter components drawn

off for further processing.

• The residue of the above process [asphalt] is fed into

vacuum distillation unit where heavier gas oils are

drawn off.

• The residue of the above process considered as a

straight run Asphalt or can be further processed. 19

Atmospheric

process

Vacuum

process](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-19-320.jpg)

![2-2: BITUMINOUS BINDING PAVEMENT MATERIALS

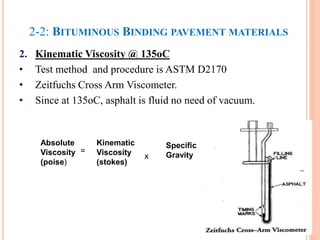

IV. Physical Tests of Asphalt Cement

The main physical tests in Asphalt can be

categorized as follow:

22

Asphalt Physical Tests

Consistency

Tests

Durability

Tests

Purity

Tests

Safety Tests Other

Tests

1 Viscosity Test

[Absolute &

Kinematic]

Thin film Oven

Test [TFO]

Solubility

Test

Flash Point

[Cleveland

Open Cup Test]

Specific

Gravity

2 Penetration Spot Test

3 Softening Point

[Ring and Ball

Test]

Rolling Thin Film

Oven Test [RTFO]

4 Ductility Test](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-22-320.jpg)

![2-2: BITUMINOUS BINDING PAVEMENT MATERIALS

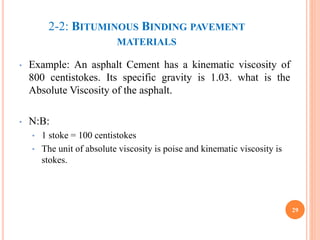

• N:B. as part of the Superpave [Superior Performing Asphalt

Pavement] there are new performance evaluating tests. Such

as

i. Pressure Aging Vessel Test – [PAV]

ii. Rotational Viscometer – [RV]

iii.Dynamic Shear Rehometer – [DSR]

iv.Bending Beam Rehometer –[BBR]

v. Direct Tension Tester – [DTT]

• However, this lecture will only focus on the conventional

tests only.

23](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-23-320.jpg)

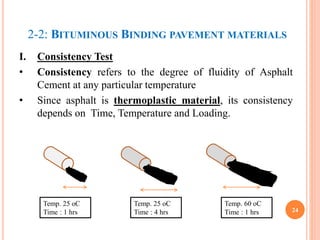

![2-2: BITUMINOUS BINDING PAVEMENT

MATERIALS

• As shown earlier, the following empirical tests are used for

measuring consistency:

1. Viscosity [Absolute and Kinematic ]

2. Penetration

3. Softening point

4. Ductility

• Before discussing each test let us look the representative

testing temperatures:

25

Temperature Condition represented

25 oC Average Pavement Temperature

60 oC Maximum Pavement Temperature

135 oC Mixing, Pumping, Spraying, etc Temp.](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-25-320.jpg)

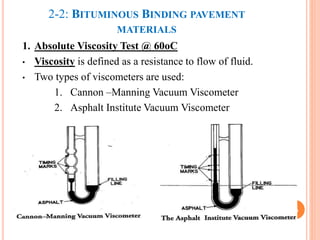

![2-2: BITUMINOUS BINDING PAVEMENT

MATERIALS

• The test method and procedure is described on ASTM D2171

• Procedures :

i. The viscometer is mounted in thermostatically controlled constant

water or oil bath at 60oC.

ii. Asphalt will be charged to the viscometer & apply partial vacuum

to assist movement.

iii. Record the time the asphalt take to pass between the time marks.

iv. Calculate the viscosity as:

i. V2 = T2 [V1/T1]

27

Where, V2 = Viscosity of the unknown material

V1 = Viscosity of standard material

T2 = Time of unknown material

T1 = Time of standard material

But [V1/T1] =calibration constant and provided by

manufacturers](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-27-320.jpg)

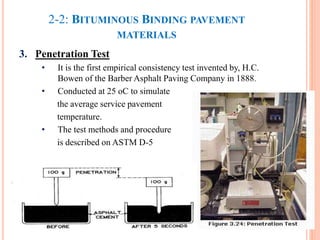

![2-2: BITUMINOUS BINDING PAVEMENT MATERIALS

• Test procedure:

1. A container of asphalt brought to a standard temperature

of 25oC in thermostatically controlled bath.

2. The sample is placed under a needle of specified

dimension.

3. The needle is loaded with 100gm weight and allowed to

penetrate for 5 sec .

4. The depth of penetration is measured on 0.1mm [dmm]

as penetration unit.

• N:B: for highly viscous asphalt the penetration is small and

vise versa.

31](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-31-320.jpg)

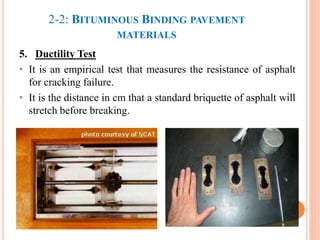

![2-2: BITUMINOUS BINDING PAVEMENT

MATERIALS

4. Softening Point Test [Ring & Ball Test]

It is the temperature at which an asphalt cement began phase

change.

Test method and procedure is ASTM D-36.

32

Procedure:

i. Fill asphalt in the brass rings

and suspend in backer filled

with water.

ii. Place the steel balls on the

asphalt.

iii. Heat the bath at a rate of

5oC/min.

iv. Record the temperature at

which the asphalt touch the

bottom arrangement.

v. Average the results of the 2

samples.](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-32-320.jpg)

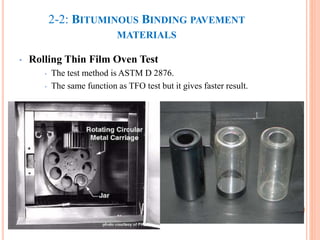

![2-2: BITUMINOUS BINDING PAVEMENT

MATERIALS

• Hence, measuring of Durability relates with measuring of

Aging.

• However, there is no direct test to measure aging. Rather,

standard tests conducted on the aged sample which simulate

the actual condition.

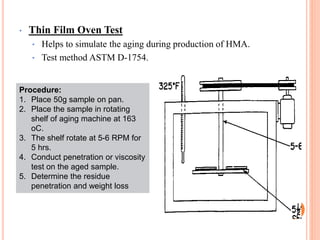

• In order to simulate the short term aging, there are two tests

in the conventional test; these are:

1. Thin Film Oven Test [TFO]

2. Rolling Thin Film Oven Test [RTFO]

37](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-37-320.jpg)

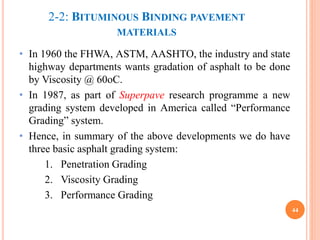

![2-2: BITUMINOUS BINDING PAVEMENT

MATERIALS

• Initially, people uses Chewing to check the softness

[“consistency”] of asphalt.

• In 1888, H.C Bowen of Barber Asphalt Paving

Company, invent the first penetration test and machine.

• In 1910, after several modifications on test machine;

penetration test become principal means of controlling

consistency at 25oC.

• In 1931 American Associations of State Highway and

Transport officials [AASHTO] published standard

specifications for Penetration Grade Asphalt Cement.

43](https://image.slidesharecdn.com/cotm4192chapter2-2bituminousmaterials-221227141146-d32b108a/85/COTM-4192-Chapter-2-2-Bituminous-Materials-ppt-43-320.jpg)