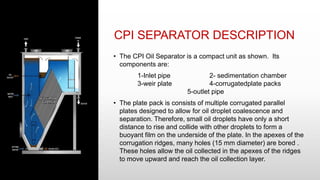

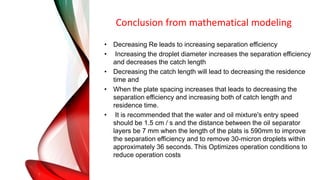

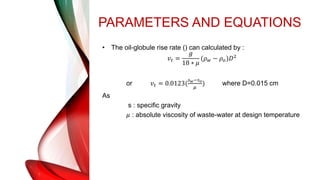

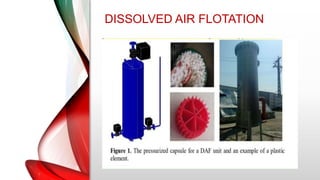

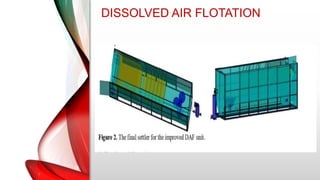

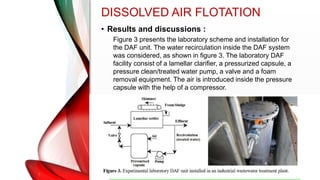

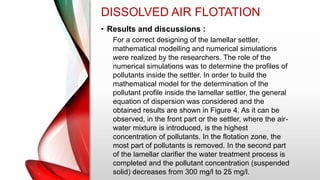

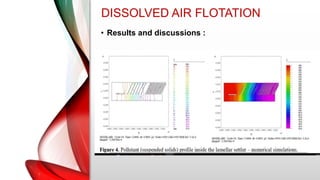

The document provides a detailed overview of the design and operational principles of a corrugated plate interceptor (CPI) separator and a dissolved air flotation (DAF) unit, both used for oil and water separation. It discusses the physics behind oil droplet coalescence, separation efficiency factors, and the construction of each system, highlighting advantages and disadvantages. It concludes with experimental results showing high efficiency in pollutant removal and the significance of innovative techniques to enhance performance in wastewater treatment.