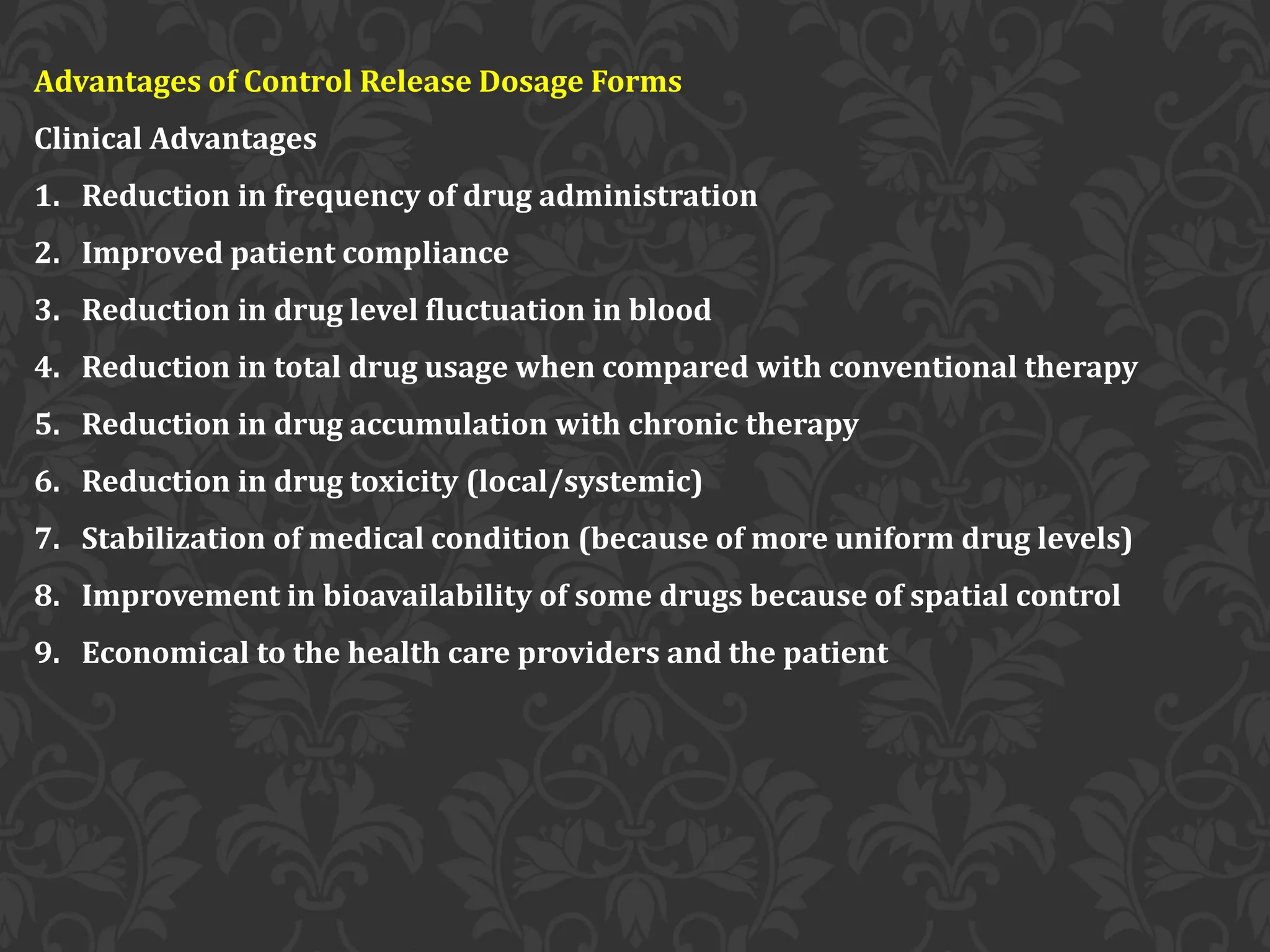

The document outlines the principles and approaches for controlled drug delivery systems, emphasizing their advantages such as improved patient compliance and reduced drug toxicity. It discusses various formulation strategies, including dissolution and diffusion-controlled systems, and describes mechanisms like ion exchange resins used for controlled release. The document also highlights the potential disadvantages of controlled release dosage forms, including the risk of dose dumping and increased costs.

![Matrix dissolution system

(a) Rigid Matrix Diffusion: Materials used are insoluble plastics such as PVP &

fatty acids.

(b) Swellable Matrix Diffusion: it is also called as Glassy hydro gels and popular

for sustaining the release of highly water soluble drugs. Materials used are

hydrophilic gums

06Examples:

Natural- Guar gum, Tragacanth.

Semi synthetic -HPMC, CMC, Xanthum gum. Synthetic -Polyacrilamides. Examples:

Glucotrol

XL, Procardia XL

The Higuchi Equation describing the drug release from this system [1]

: Q = [DƐ/T (2A-Ɛ Cs.t)] 1/2 Where Q=amt of drug release per unit surface area at

time t,

D=diffusion coefficient of drug in the release medium, Ɛ=porosity of the matrix,

Cs=solubility of

drug in release medium, T=tortuosity of matrix, A=concentration of drug present

in matrix per

unit volume.

Rate controlling step: Diffusion of dissolved drug in matrix.](https://image.slidesharecdn.com/unitinoveldrugdeliverysystem-240729090716-2fddf233/75/CONTROLLED-RELEASE-DRUG-DELIVERY-SYSTEM-I-11-2048.jpg)