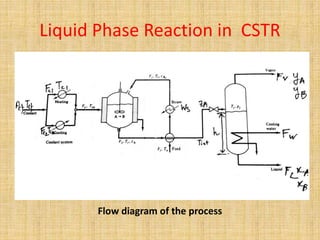

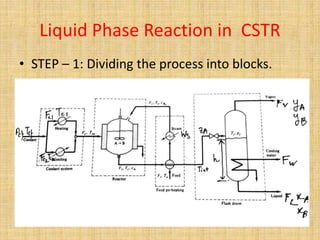

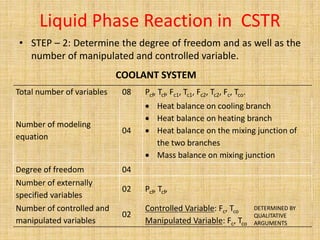

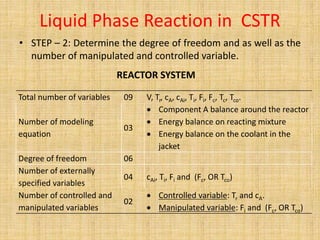

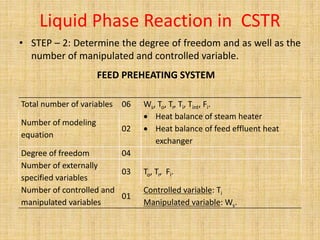

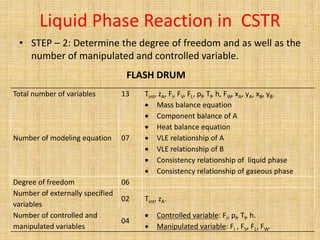

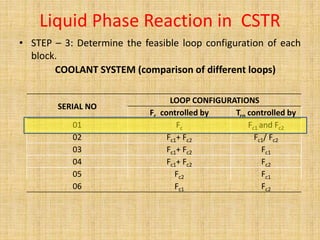

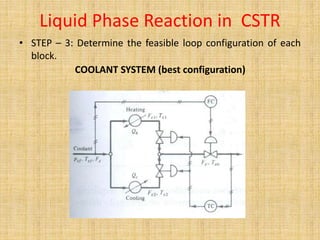

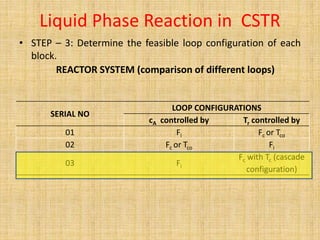

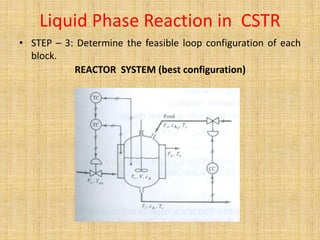

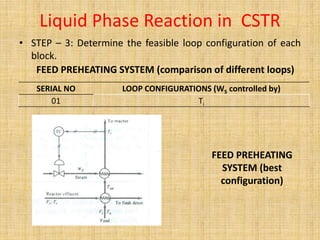

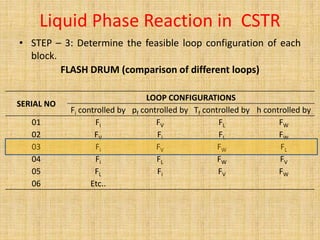

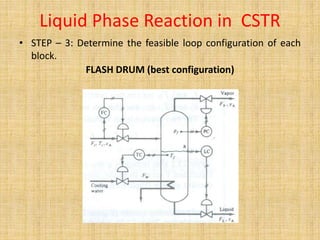

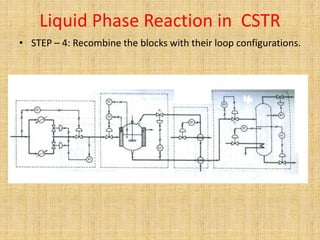

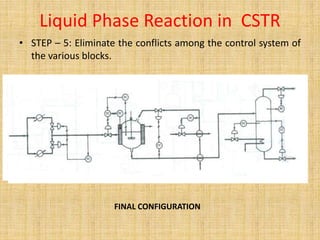

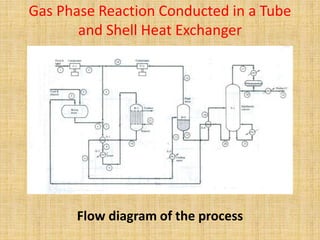

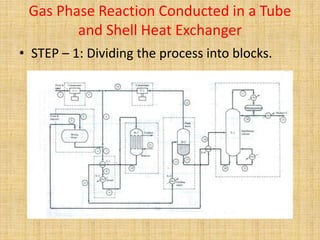

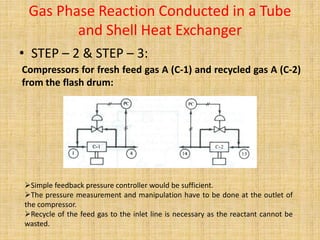

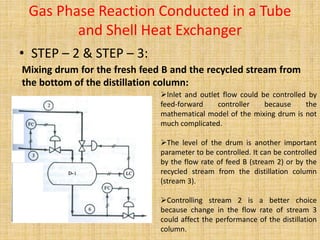

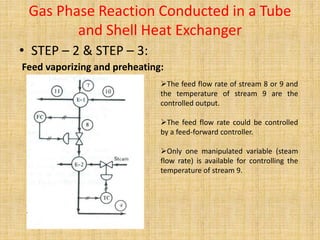

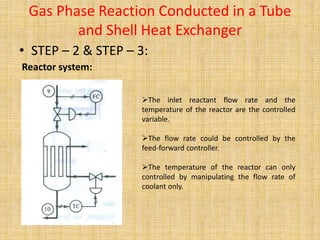

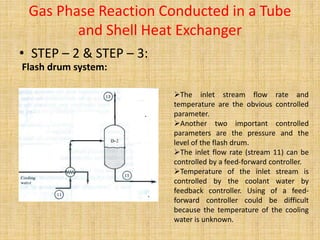

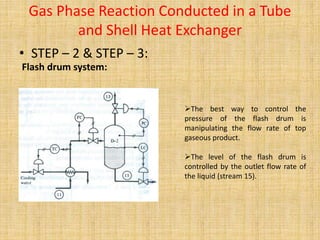

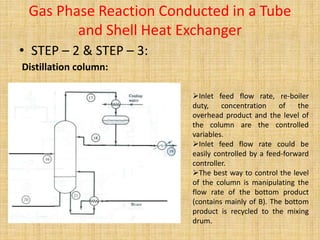

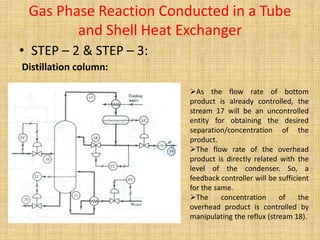

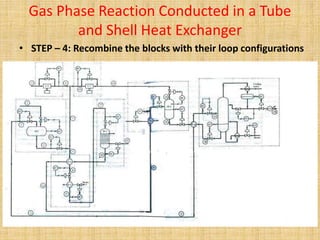

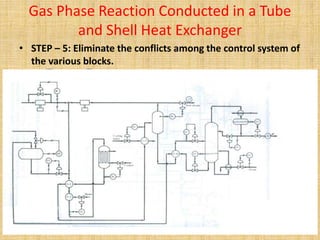

The document outlines the configuration of control loops in interacting units for chemical processes, emphasizing the need to divide processes into blocks and analyze their control configurations to enhance system performance. It details the steps to determine degrees of freedom and controlled/manipulated variables for specific block systems such as liquid and gas phase reactions. The approach is supported by examples of control configurations used in various chemical engineering scenarios.