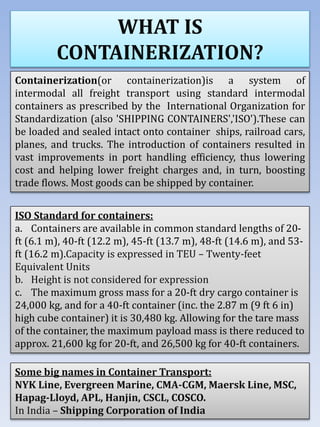

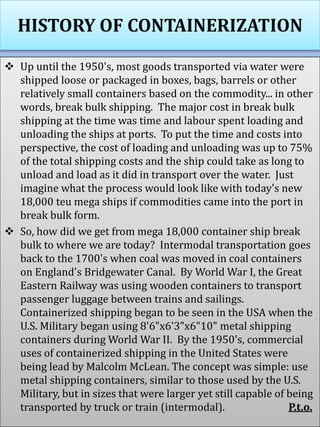

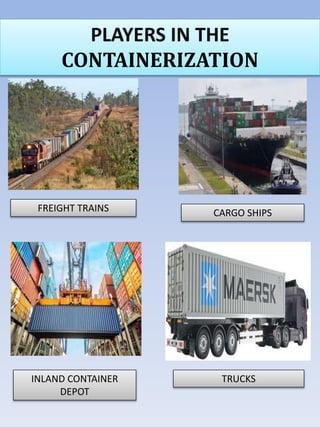

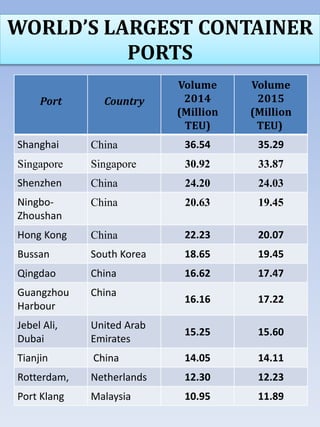

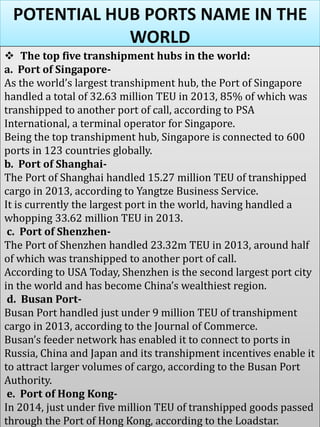

Containerization refers to the use of standard intermodal containers in freight transport. It has led to vast improvements in port efficiency and lower shipping costs. The key developments were the standardization of container sizes and specifications in the 1960s and the use of container ships, trains, trucks and ports. The top five container ports globally are Shanghai, Singapore, Shenzhen, Ningbo-Zhoushan and Hong Kong. The main advantages of containerization are standardized containers that can be transported anywhere by multiple modes, flexibility, lower costs, and increased speed of transport. Potential requirements for hub ports include location on major shipping routes and access to large hinterlands via multiple transport modes.