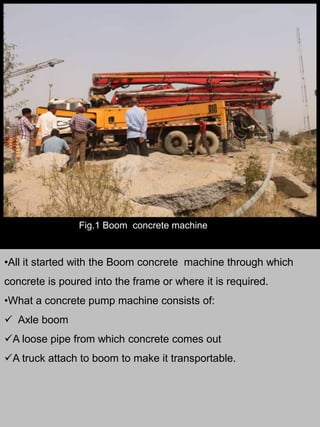

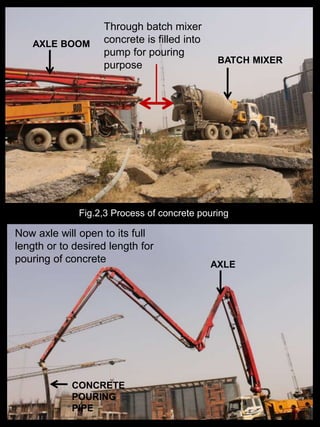

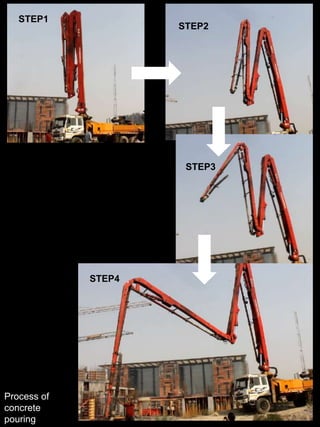

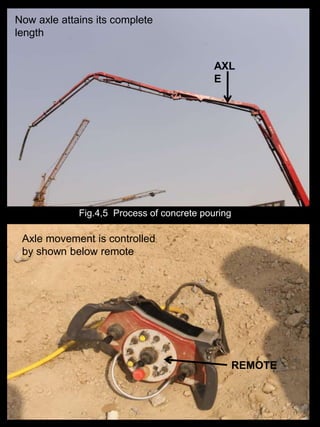

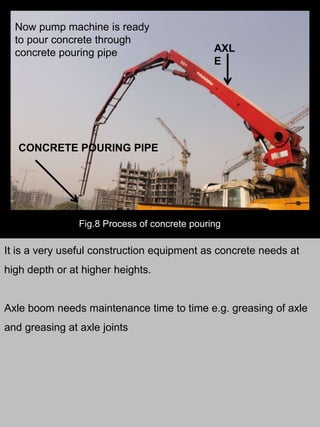

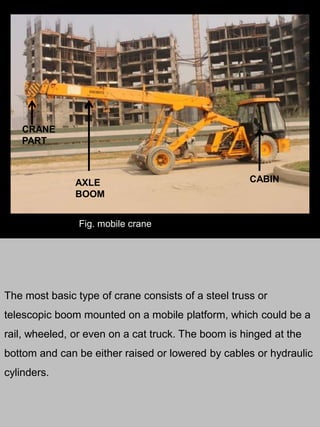

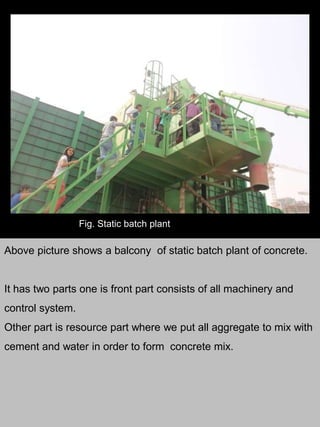

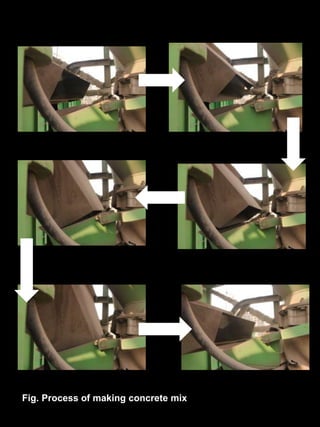

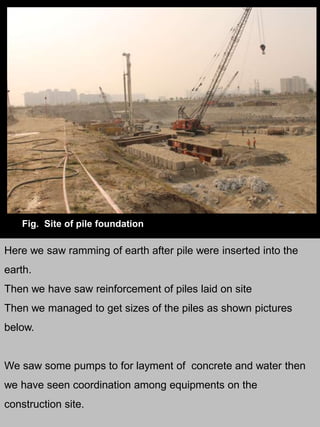

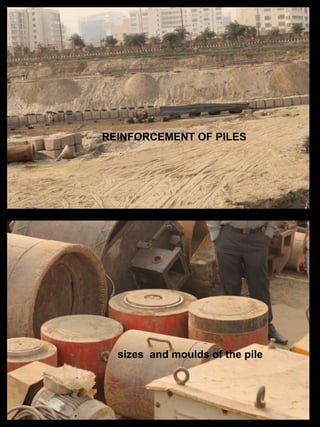

The document summarizes a site visit to a construction site at Jaypee Wish Town in Noida. It describes some of the key equipment observed on site including a tower crane used to lift materials for tall buildings, a concrete pump machine consisting of an axle boom and pipe to pour concrete, and a batch mixer to fill concrete into the pump. Process steps of pouring concrete are outlined. Other equipment mentioned include a mobile crane, static batch plant to mix concrete ingredients, and pile foundations with reinforcement laid on site.