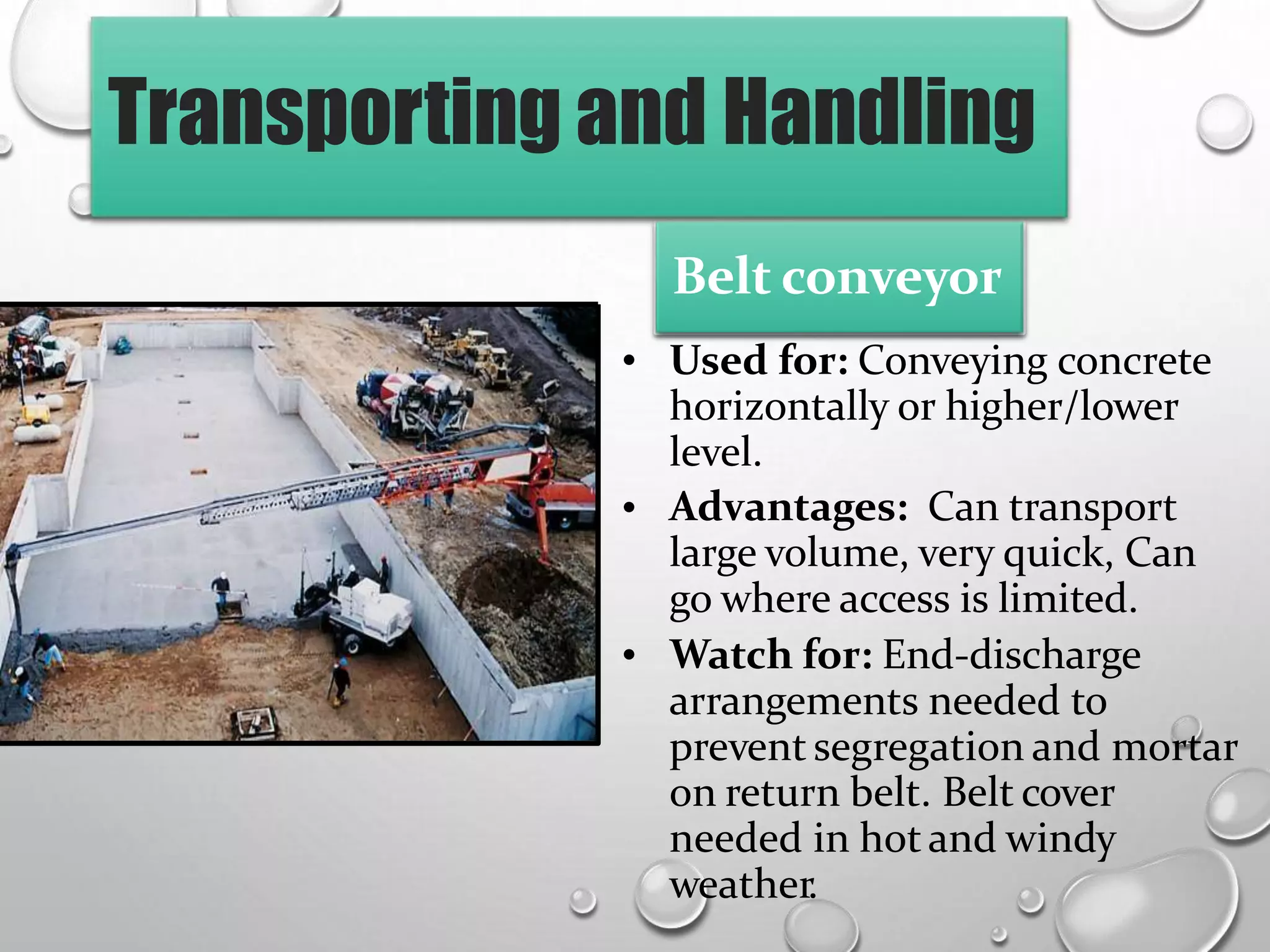

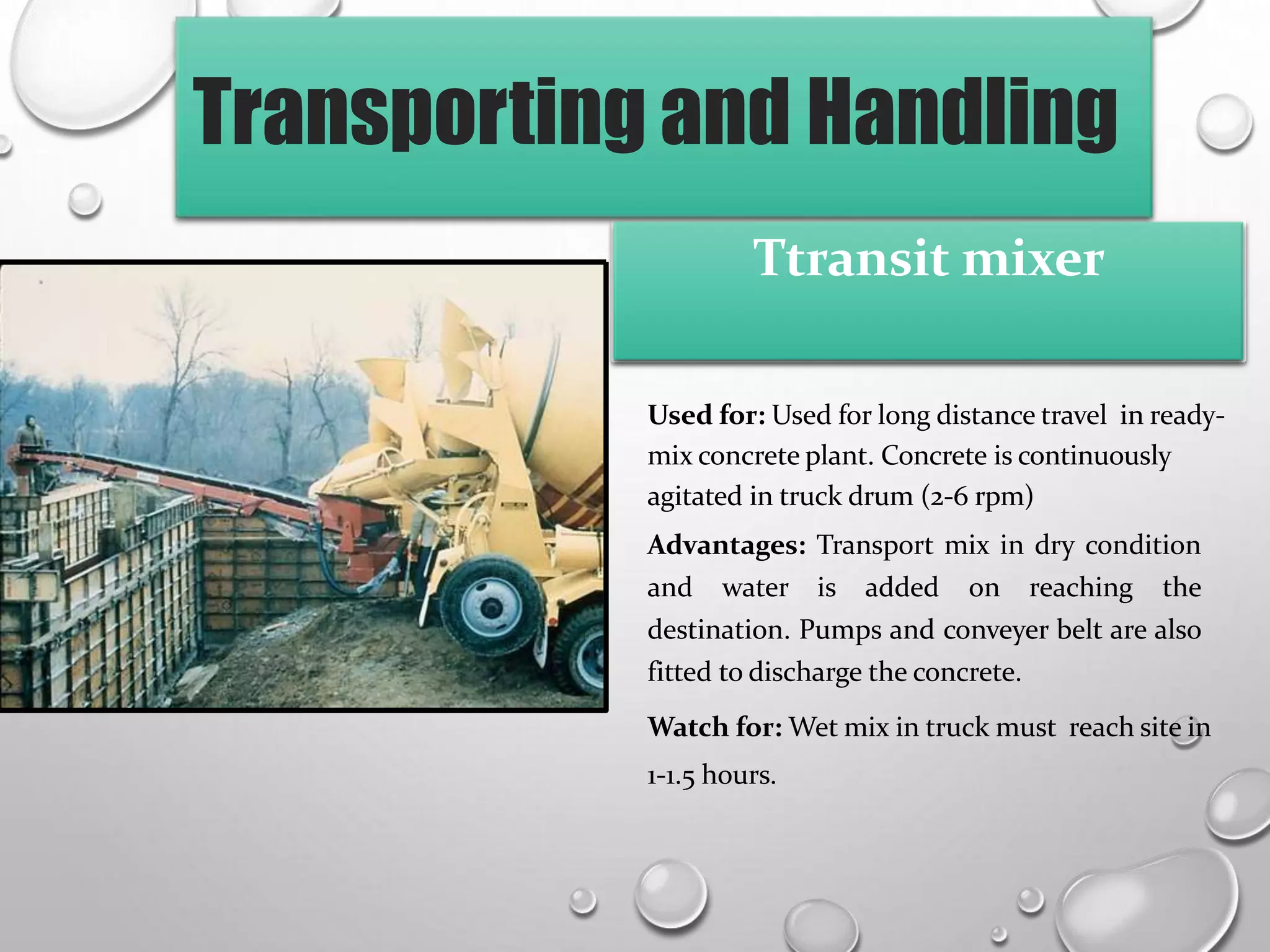

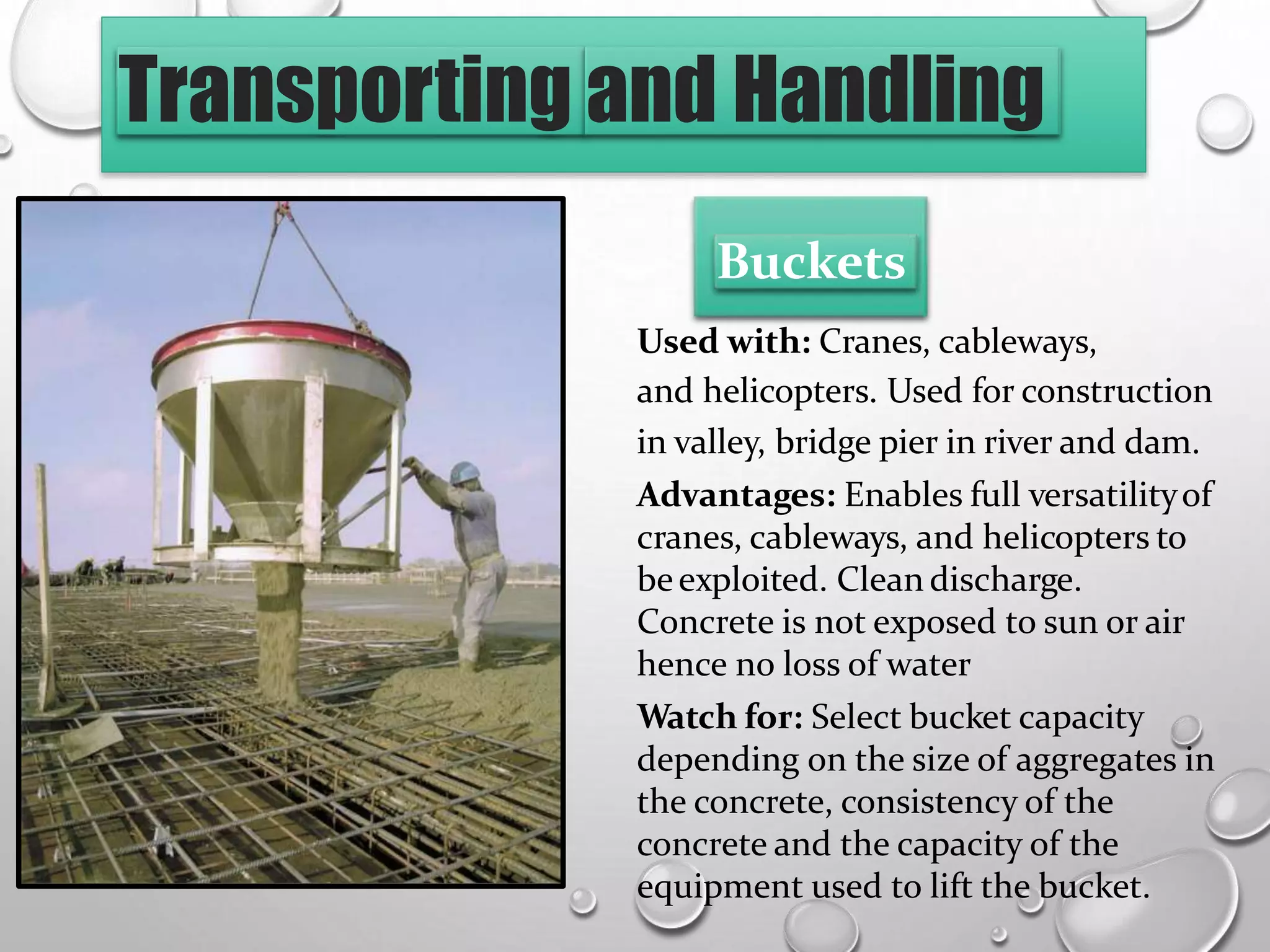

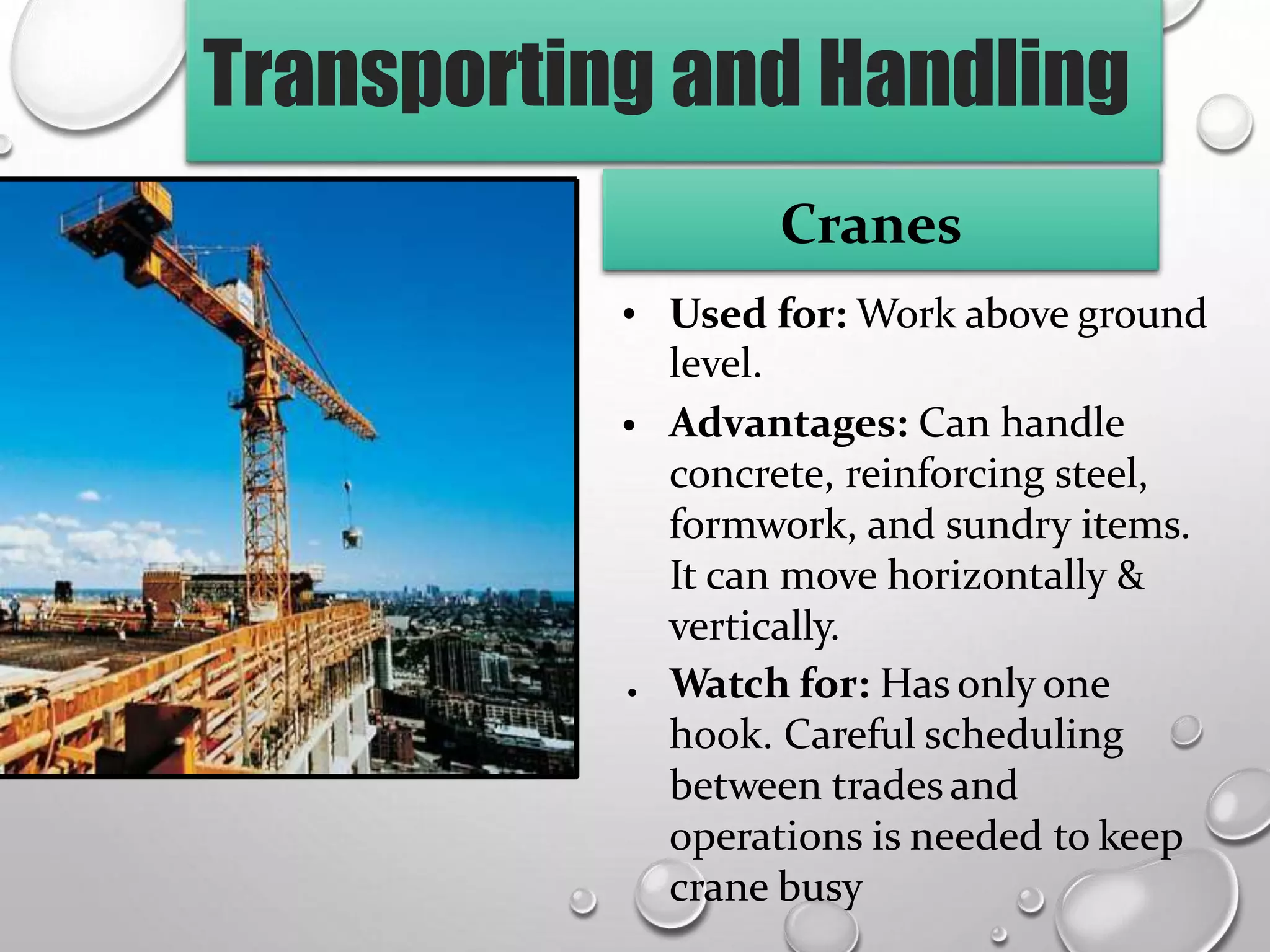

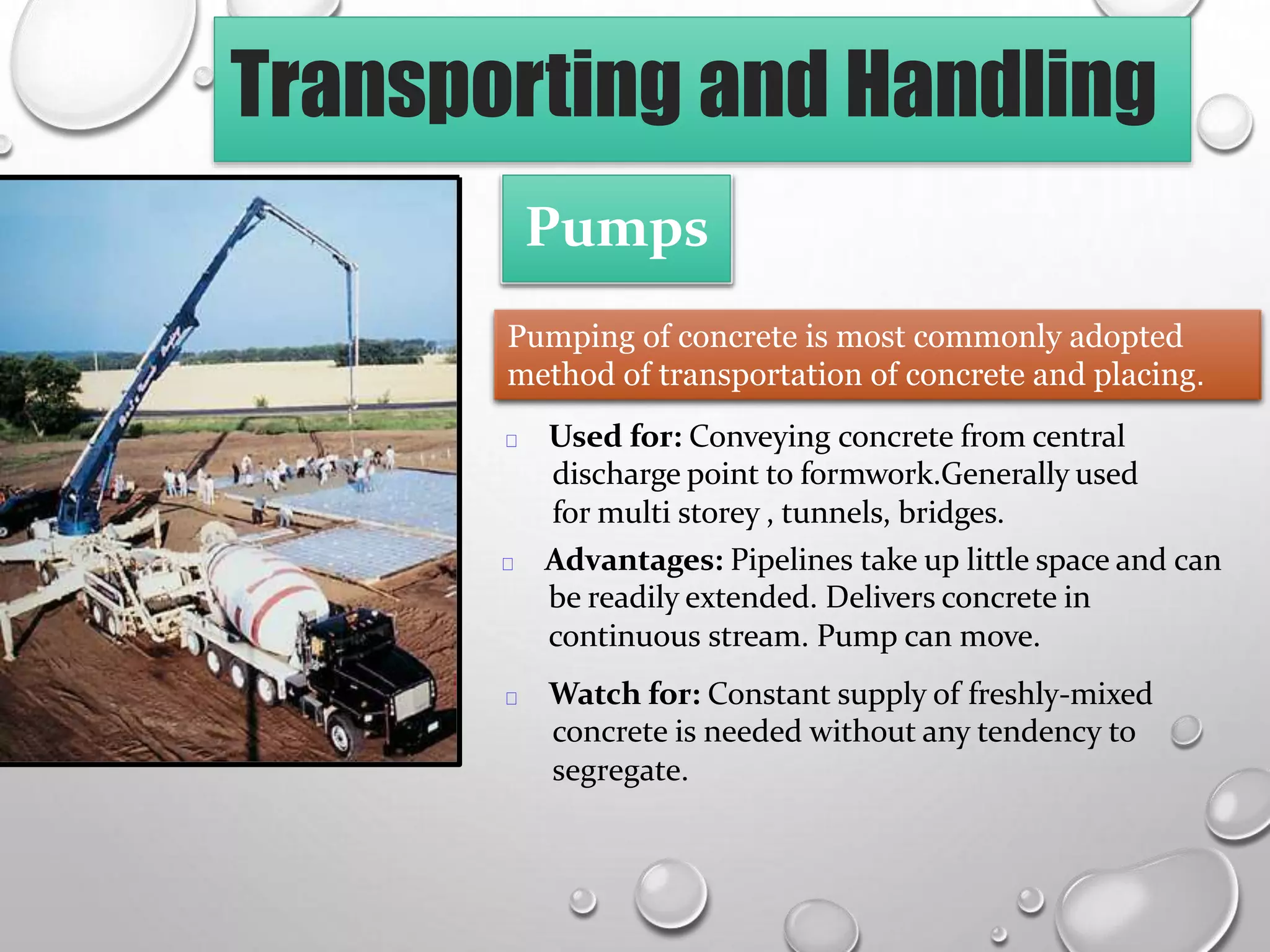

The document discusses various methods for transporting and handling concrete on construction sites, including wheelbarrows, skips and hoists, belt conveyors, transit mixers, buckets used with cranes and helicopters, pumps, and screw spreaders. A wide range of equipment has been developed to transport concrete given modern demands, with considerations for advantages and limitations of each method depending on the transport distance and placing conditions. Pumps are commonly used to convey concrete over long distances both horizontally and vertically on multi-story buildings and bridges.